Device for semi-aerobic dry fermentation of sludge and feces mixture

A fermentation device, quasi-aerobic technology, applied in sludge treatment, biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of landfill not meeting the requirements, huge treatment burden, high moisture content of sludge, etc. problem, to achieve the effect of reducing the cost of blast aeration, good aerobic effect and high electricity cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

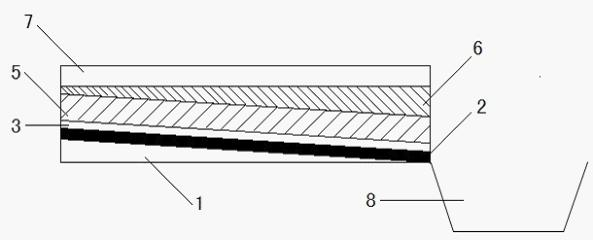

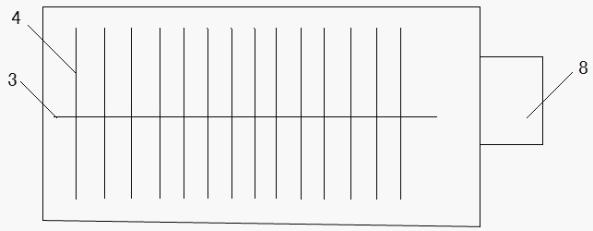

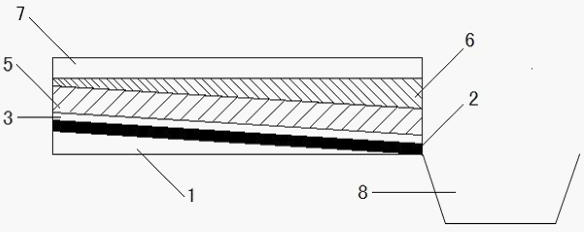

[0020] see figure 1 , figure 2 As shown, the mixed quasi-aerobic drying and fermentation device for sludge and feces includes a base 1 with a slope, on which an HDPE anti-seepage film 2 is first laid, and on the HDPE anti-seepage film 2 is laid a ventilating main pipe 3 and Ventilation branch pipe 4, described ventilating branch pipe 4 is vertically connected on described ventilating main pipe 3 both sides respectively, and cobblestone 5 is placed all to bury described ventilating main pipe 3 and described ventilating branch pipe 4, compost fermentation raw material 6 is piled up on described cobblestone 5 The composting fermentation raw material 6 is covered with composted and fermented sludge composting products 7, and a sump 8 is set at the bottom of the base 1.

[0021] Further, the slope i of the base 1 is 1%-5%.

[0022] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com