Polylactic acid toughening and modifying agent and preparation method thereof

A technology of toughening modifier and polylactic acid, applied in the field of preparation of polylactic acid toughening modifier, can solve the problems of high cost, increase in cost, increase market competitiveness, etc., and achieve good compatibility and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

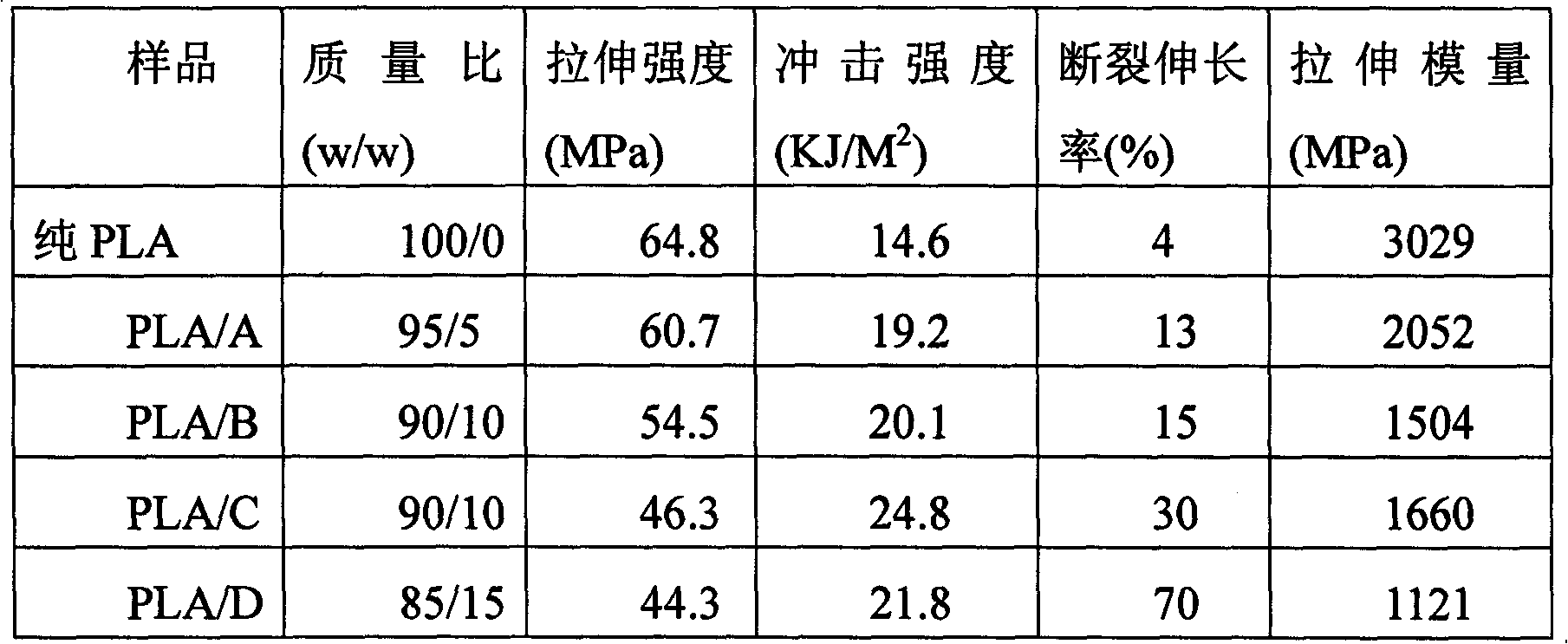

Examples

Embodiment 1

[0023] Castor oil and L-lactic acid are fed according to the material ratio of 1:2, stannous chloride is used as a catalyst, and reacted for a certain period of time under a certain vacuum at 150°C. After the product is purified, toughener A is obtained, and the number average is measured by GPC. The molecular weight is 6810, ready for use.

Embodiment 2

[0025] Feed polycastor oil and DL-lactic acid according to the material ratio of 1:3, stannous octoate is used as the catalyst, and the reaction temperature is 170°C. First, react for a period of time under nitrogen atmosphere, and then react under a certain degree of vacuum, and the reaction is over. The final product was purified to obtain toughening agent B, and the number average molecular weight was 18750 as measured by GPC, and it was ready for use.

Embodiment 3

[0027] Feed castor oil and succinic acid according to the material ratio of 1:1.5, and directly polycondense at 180 ° C. The reaction is first reacted under a nitrogen atmosphere for a period of time, and then reacted under a certain degree of vacuum. After the reaction is completed, a toughening agent is obtained. C, the number average molecular weight measured by GPC is 3052, ready for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com