Multi-component warp imitated yarn-dyed fabric and preparation method thereof

A technology of imitating dyed weaving and warp yarns, applied in the textile field, can solve the problems of poor fabric performance, long working time, discontinuity, etc., and achieve the effects of good elasticity and wearability, energy saving and consumption reduction, good shaft rate, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

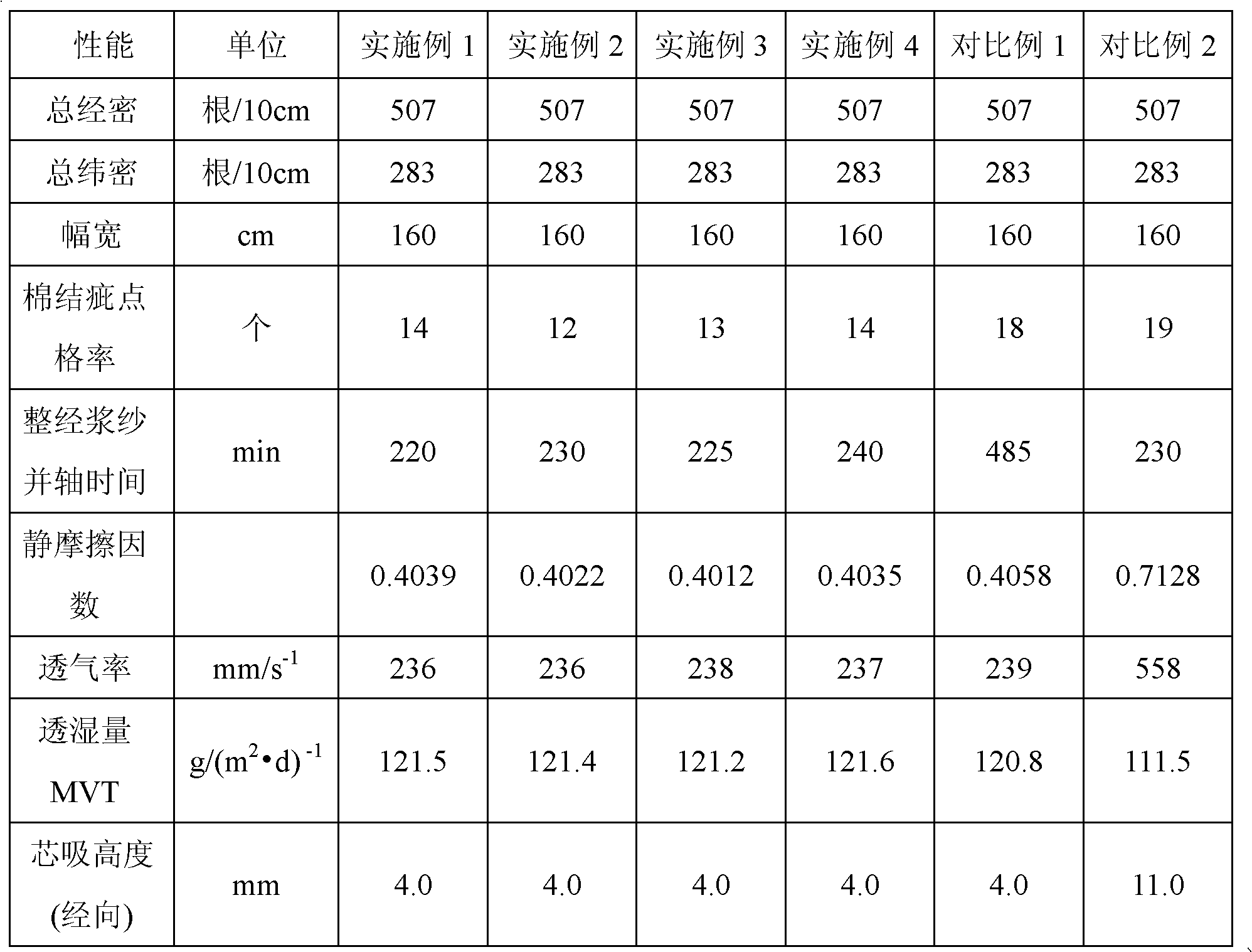

[0021] Embodiments 1 to 4 are specific embodiments of the present invention, and Embodiment 2 is the best embodiment of the present invention.

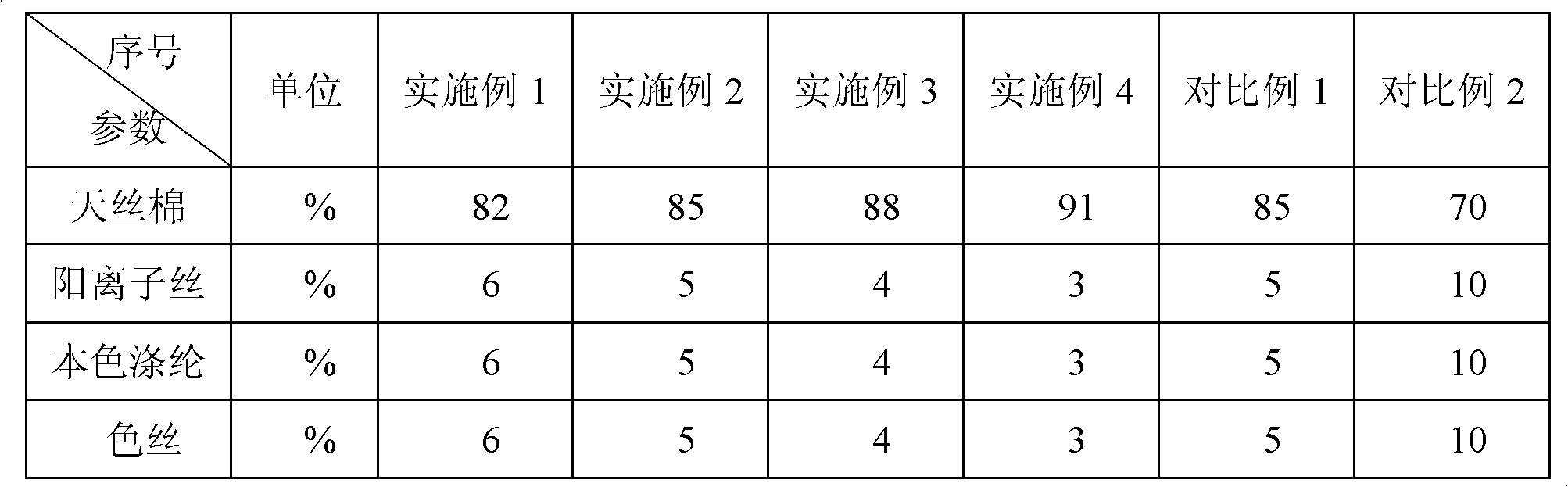

[0022] Table 1 Fiber composition of multi-element warp imitation yarn-dyed fabric

[0023]

[0024] Wherein, the preparation method of embodiment 1 and embodiment 2 comprises the following steps:

[0025] A warping

[0026] ①Warping of natural polyester, cationic yarn and colored yarn

[0027] Use a short fiber warping machine to warp natural-color polyester, cationic yarn and colored yarn, use one warp beam for natural-color polyester, and use one warp beam for cationic yarn and colored yarn according to the number of warp roots in a 1:1 arrangement. The warping speed is 400m / min, when unwinding, use a lightweight thin cloth to cover two adjacent bobbins in parallel, the tension of the yarn is 2CN, the distance between the cradle of the warping tension arm and the magnetic eye is 20cm on both sides, and the winding hardness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com