Vacuum impregnation device and method of fiber composite material

A fiber composite material, vacuum impregnation technology, applied in the processing of textile materials, liquid/gas/vapor textile processing, textiles and papermaking, etc. Guaranteed uniformity, simple operation and improved impregnation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

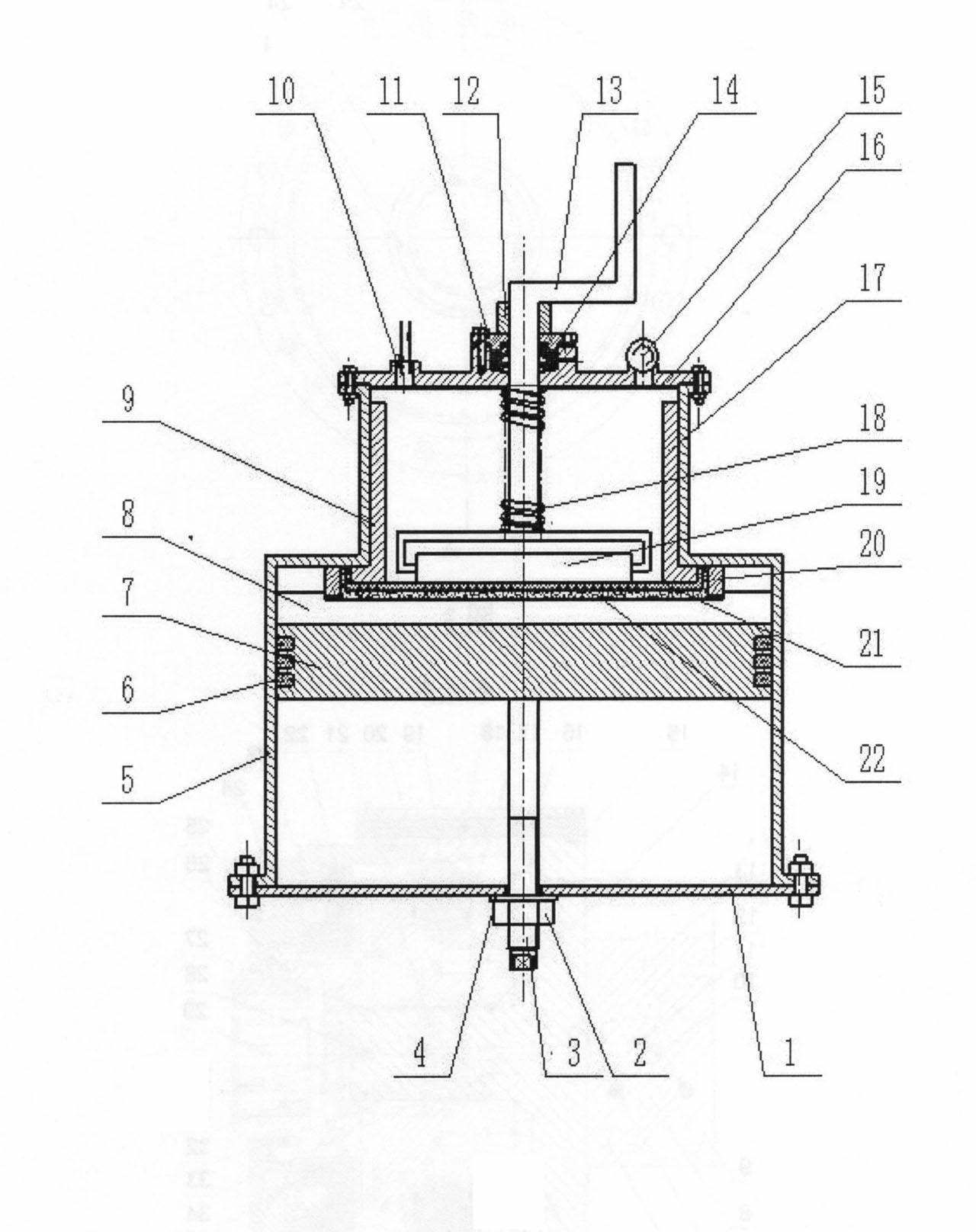

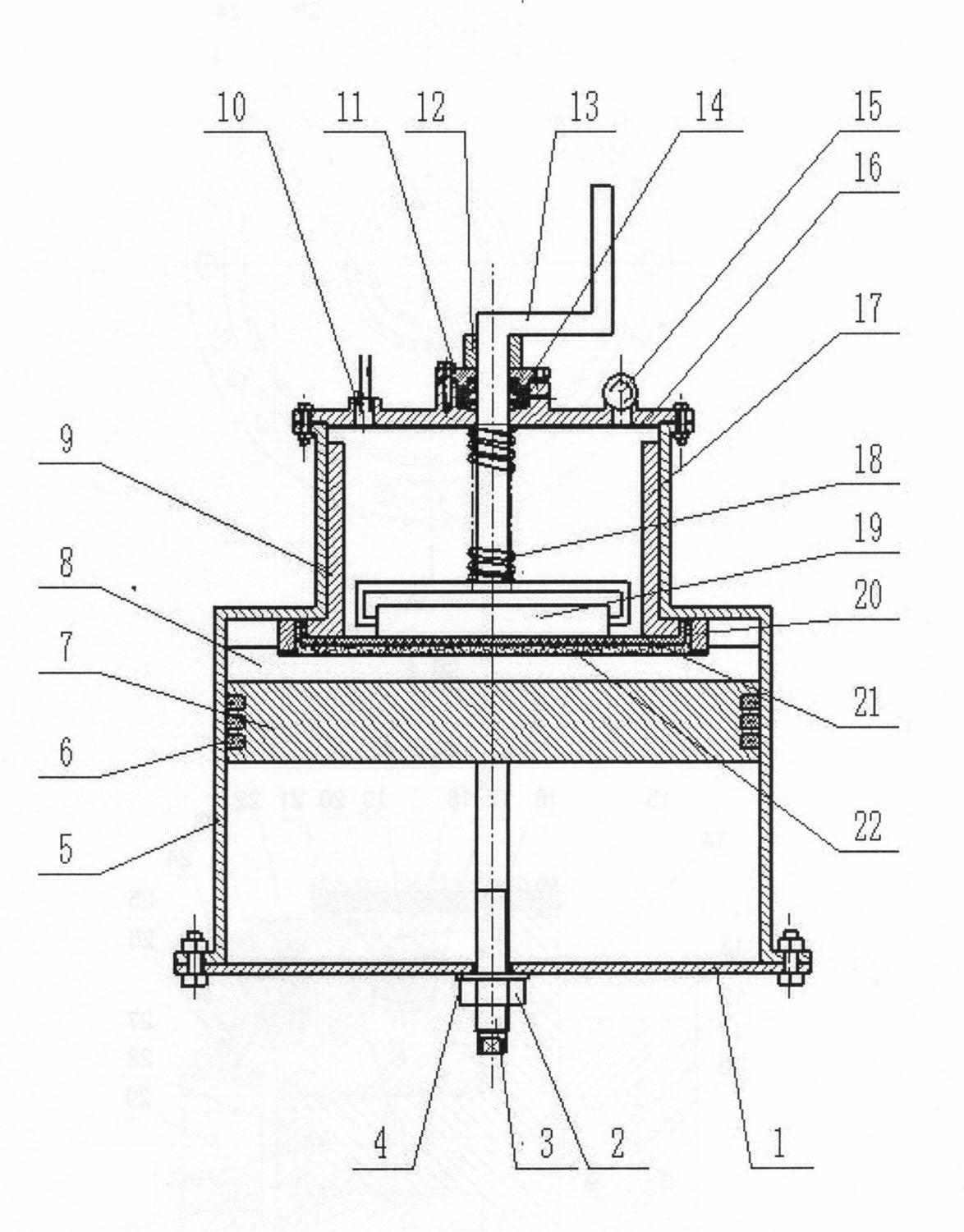

[0015] exist figure 1 In the schematic diagram of the mechanism of a vacuum impregnation device for fiber composite materials shown, the cylinder body 5 is convex, and its bottom is fixed on the frame 1 with bolts. Pass through the through hole, and fix it on the frame with the feed screw nut 2, a sealing gasket 4 is provided between the nut and the frame, and the lower end surface of the piston 7 equipped with the sealing ring 6 is connected with the end surface of the feed screw column, The upper end face of the piston is fixed to the PTFE plate 8 with grooves. Liners 9 are arranged on both inner sides of the raised part of the cylinder body, a support net 21 is fixed on the lower end face of the bush, and squeeze sleeves 20 are provided at both ends of the support net. Both ends of the upper cover of the sealing chamber 16 are fixed on the top of the cylinder body with bolts. The rotating shaft 13 passes through the through hole of the upper cover of the sealing chamber, a...

Embodiment 2

[0019] The method of vacuum impregnating the fabric using the equipment of Example 1: first, the glass fiber / PTFE fabric is laid flat on the support net, the support net is placed on the lower end surface of the bushing, and the support net and the fabric are fixed by a squeeze sleeve on the bushing; fix the grooved PTFE plate on the upper face of the piston. Spray a layer of resin evenly into the groove of the PTFE board through the paint spray gun, and the amount of resin sprayed is determined by the mass difference between the front and back of the paint spray gun measured by the electronic balance.

[0020] Then, after vacuuming the vacuum impregnation device to 50kpa, close the filling / deflation port. Relying on the spiral motion to push the piston displacement, so that the fiber fabric is in contact with the resin for impregnation; adjust the spring compression between the rotating shaft and the cylinder to maintain a certain pressure between the PTFE roller and the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com