Precast concrete sandwiched heat-insulation external wall

A prefabricated concrete and prefabricated concrete slab technology, applied in thermal insulation, walls, building components, etc., can solve the problems of not considering the waterproof and aging of the sandwich insulation layer, inability to bear the load, cracks in the outer wall, etc., so as to improve the waterproof performance of the wall and save energy. The effect of material and labor, high wall flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

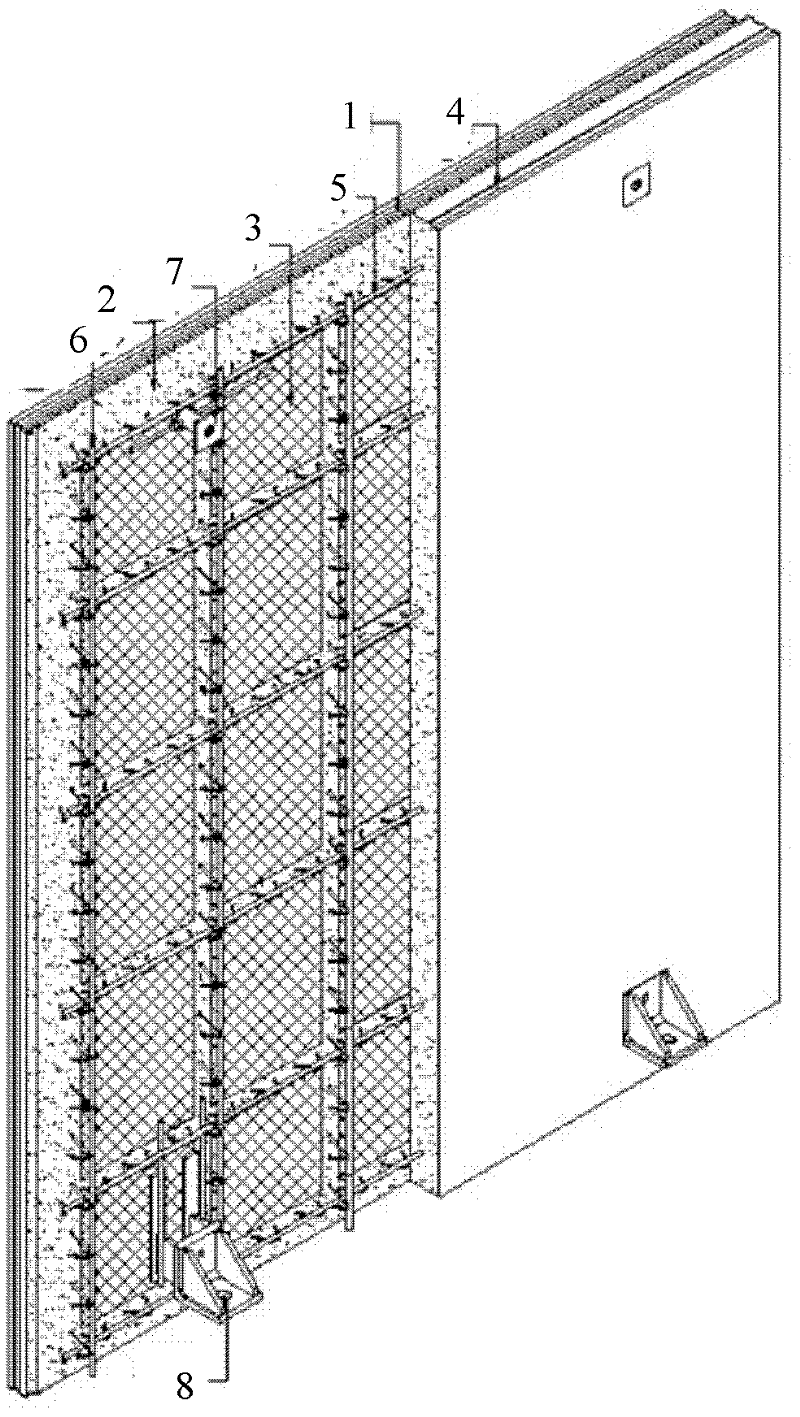

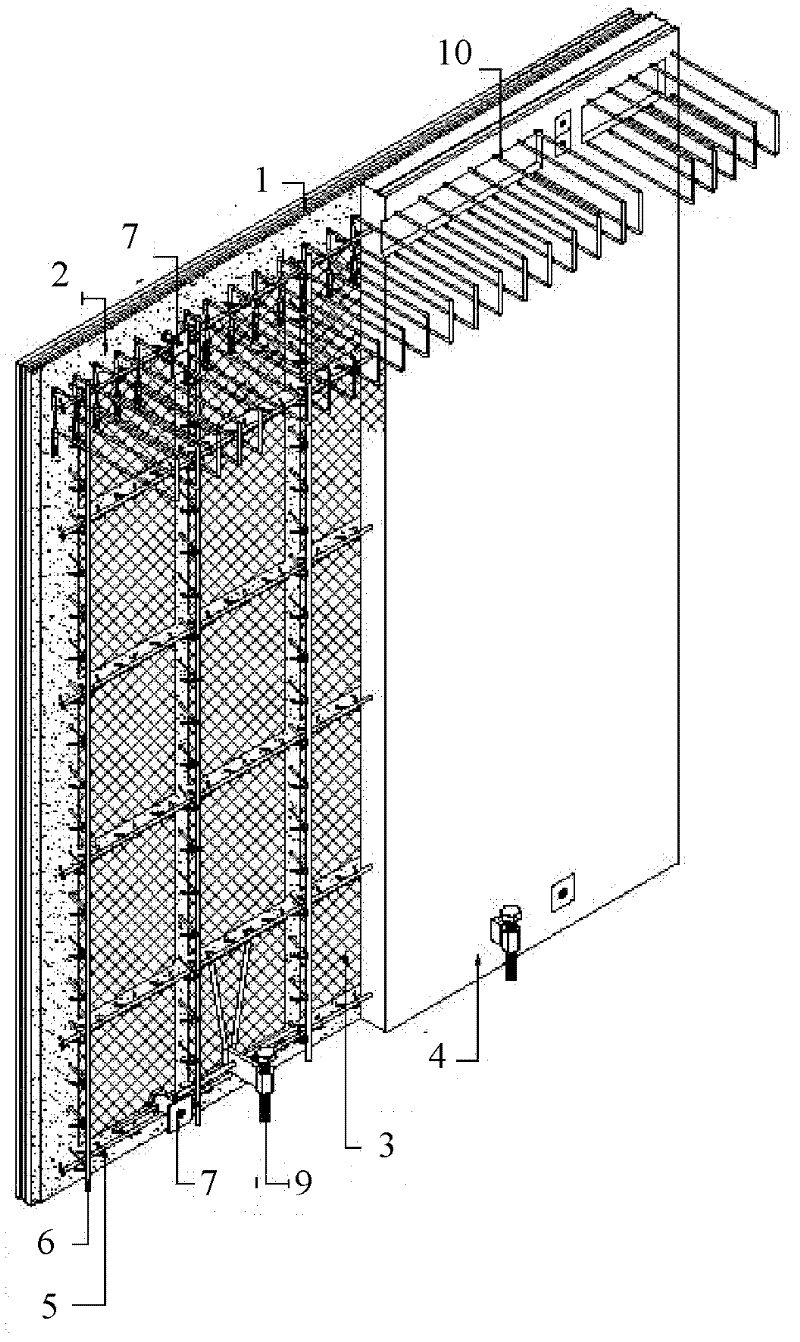

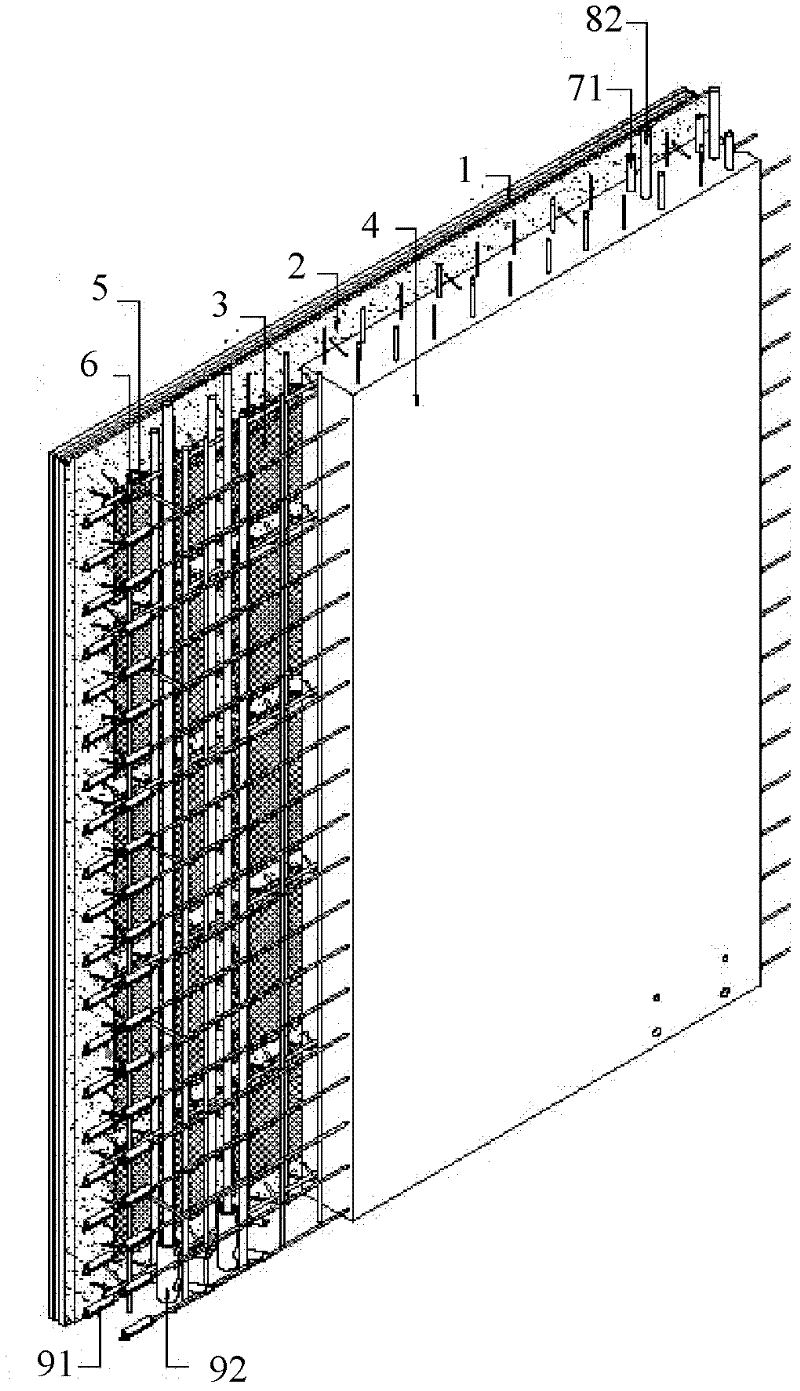

[0035] Such as figure 1 As shown, the prefabricated concrete sandwich thermal insulation exterior wall of the present invention includes an outer prefabricated reinforced concrete slab 1, a transverse superimposed reinforcement 5, a longitudinal superimposed reinforcement 6, a thermal insulation board 3, a thermal insulation and waterproof mortar 2, an inner prefabricated reinforced concrete slab 4 and the main body Embedded parts 7 for bearing out-of-plane loads for structural connections, embedded parts 8 for self-weight (such as Figure 8 , Figure 9 shown). The shape of the plate end meets the waterproof requirements of the structure. The thickness of the outer prefabricated reinforced concrete slab 1 shall not be less than 50 mm according to the design specifications, and the steel bars 41 (such as Figure 7 shown), the diameter and spacing of the steel bars are determined by the load. Folding ribs 5 and 6 (such as Figure 5 and Figure 6 (shown) not only has the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com