Pressure lubricating integral barrel-shaped tappet device

An integral, barrel-shaped technology, applied in fuel injection devices, charging systems, engine components, etc., can solve the problems of not easily dissipating frictional heat, reducing stiffness and strength, increasing lateral pressure and friction, and improving fatigue. The effect of contact life, increased load-carrying capacity, and reduced number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

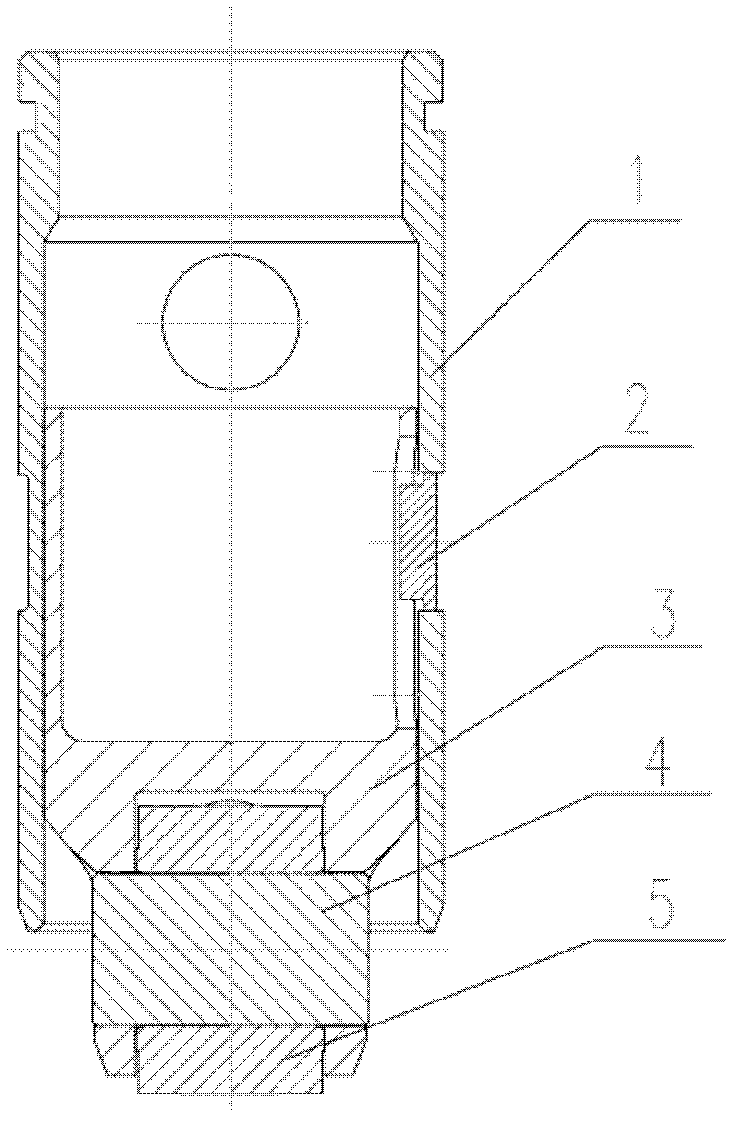

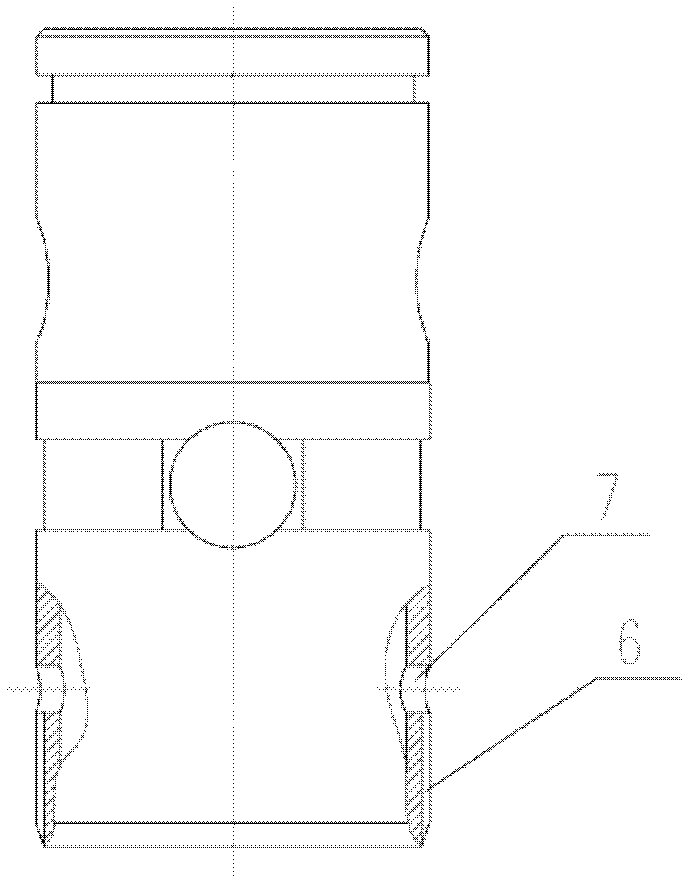

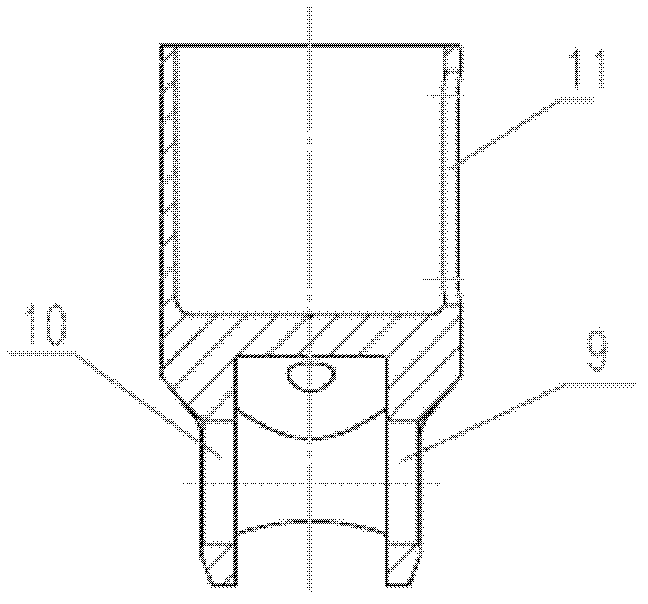

[0020] The best embodiment of the present invention is as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown: a pressure-lubricated integral barrel-shaped tappet device, which mainly includes a support sleeve 1, a guide key 2, a tappet body 3, a roller pin 4, and a roller 5. It is characterized in that the tappet body 3 is provided with two Through hole 8, roller pin hole 9, roller pin hole 10 and guide groove 11, roller 5 is set on the roller pin 4, installed between roller pin hole 9 and roller pin hole 10 of tappet body 3, tappet body 3 , roller pin 4 and roller 5 are assembled into one, assembled in the support sleeve 1, relying on the guide key 2 to guide and limit in the tappet body wall guide groove 11.

[0021] The above-mentioned roller pin 4 and the tappet body 3 adopt an interference fit, the interference amount is 0.01-0.039mm, the roller 5 and the roller pin 4 are clearance fit, the gap is 0.071-0.122mm, the tappet body 3 and the support sleeve 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com