Efficient and energy-saving electric heating warmer

A high-efficiency, energy-saving, heater technology, applied in heating methods, electric heating systems, lighting and heating equipment, etc., can solve the problems of high operating costs, short service life of radiators, high energy and water consumption rates, and achieve low operating costs. , Solve the effect of slow heating and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

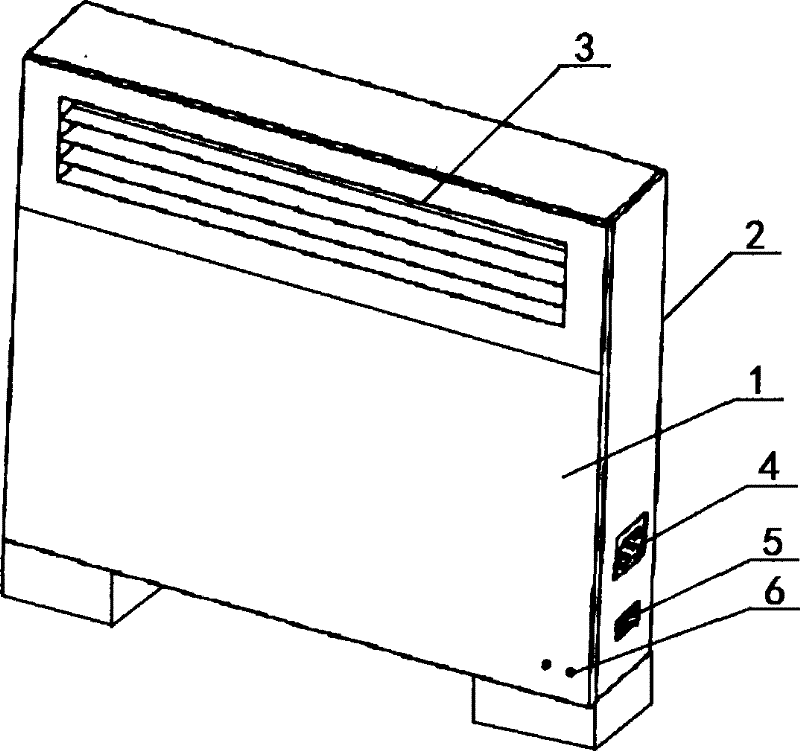

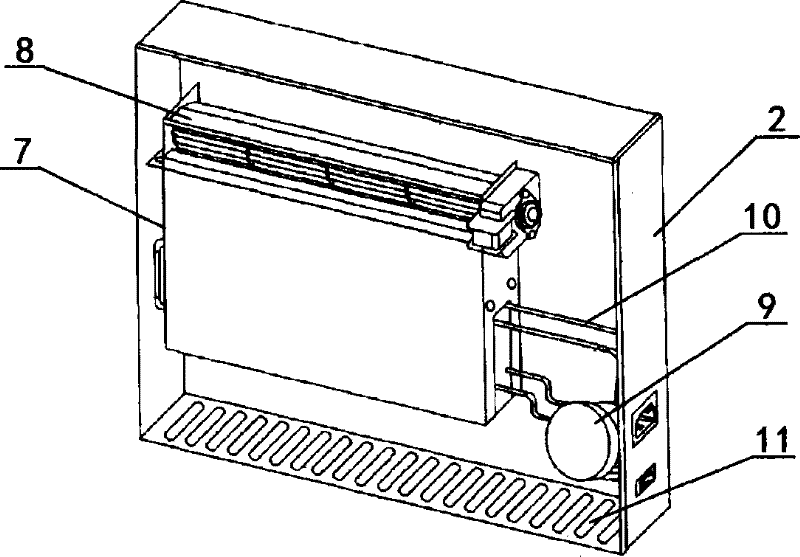

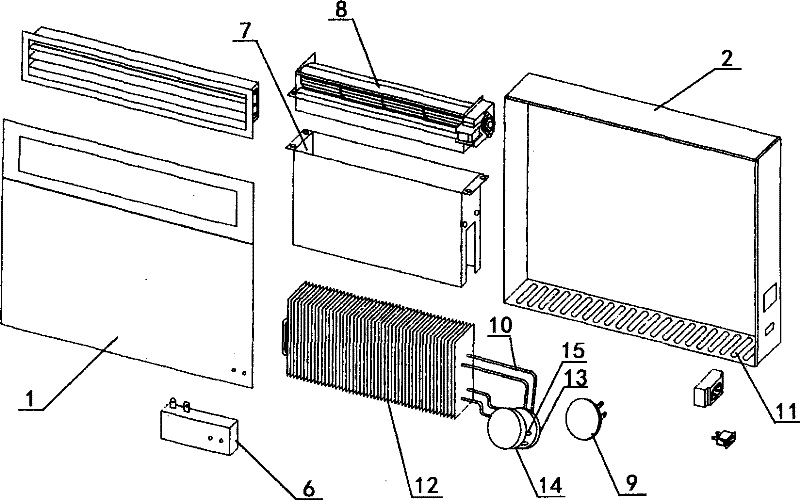

[0019] Such as Figure 1-3 As shown, the high-efficiency energy-saving electric heating heater according to the embodiment of the present invention includes a casing 2, a loop heating unit 7, and a heating plate 9. A front panel with a decorative layer is installed on the casing 2 and the outer surface. The cover plate 1 is also provided with an air outlet 3 at the upper or lower position of the front cover plate 1. At the same time, a loop control unit 7 with an outer layer of the windshield is installed in the inner cavity of the casing 2 and is located in the loop control unit. Several rows of condensers 12 are arranged inside 7; the top of the loop control unit 7 is connected to the induced draft fan 8 and the position of the air grille of the induced draft fan 8 is at the air outlet 3. Disk 9, a liquid storage chamber 14 and an evaporator 13 are respectively arranged on both sides of the heating disk 9, and the liquid storage chamber 14 and the evaporator 13 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com