Silicon micro two-dimension acceleration sensor based on self-resonant technology

An acceleration sensor, self-resonance technology, applied in the field of MEMS sensors, can solve the problems of cross-interference, inconsistent spindle sensitivity, etc., to achieve the effect of not easy to distort error, save A/D conversion, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

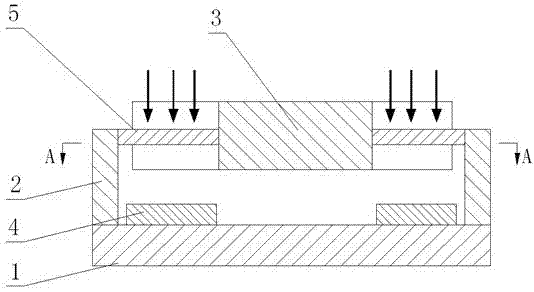

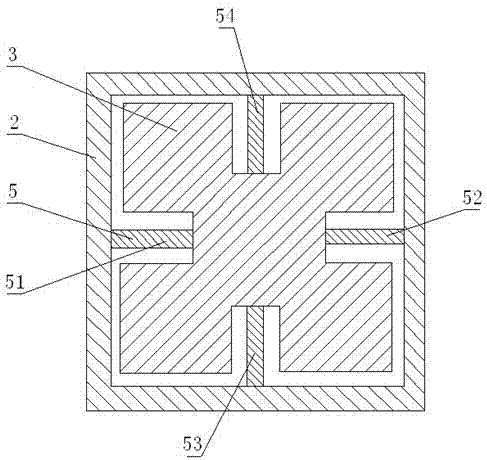

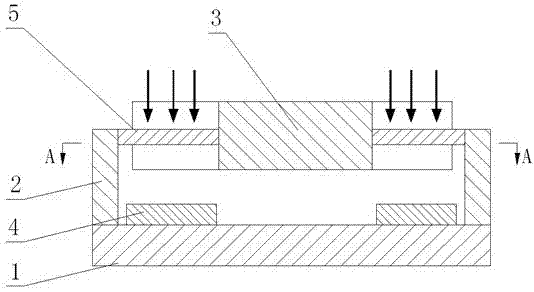

[0018] figure 1 It is a schematic diagram of the structure of a silicon micro two-dimensional acceleration sensor based on self-resonance technology, figure 2 for figure 1 The cross-sectional view along the direction A-A is shown in the figure. A silicon micro two-dimensional acceleration sensor based on self-resonance technology, comprising a substrate 1, a fixed support 2, an inertial mass 3, a PN junction 4 and a resonance microbeam 5. The fixed support 2 is a cylindrical structure, and the bottom end of the fixed support 2 is fixed on the substrate 1. In this embodiment, the substrate 1 has a rectangular structure, and the cross section of the fixed support 2 is also a rectangular structure. The bottom end of the fixed support 2 The bottom end is sealed by the substrate 1 . The inertial mass 3 is in the shape of a cloverleaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com