Double-ended high-power gas discharge lamp

A gas discharge lamp, high-power technology, applied to the parts of gas discharge lamps, etc., can solve the problems of easy looseness of the lamp head, unsafe use, high temperature, etc., to improve light output efficiency, safe and reliable use, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

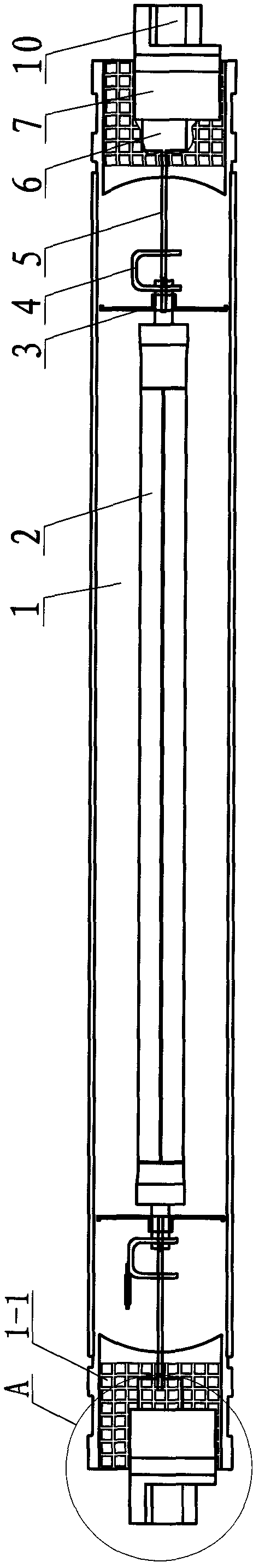

[0012] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

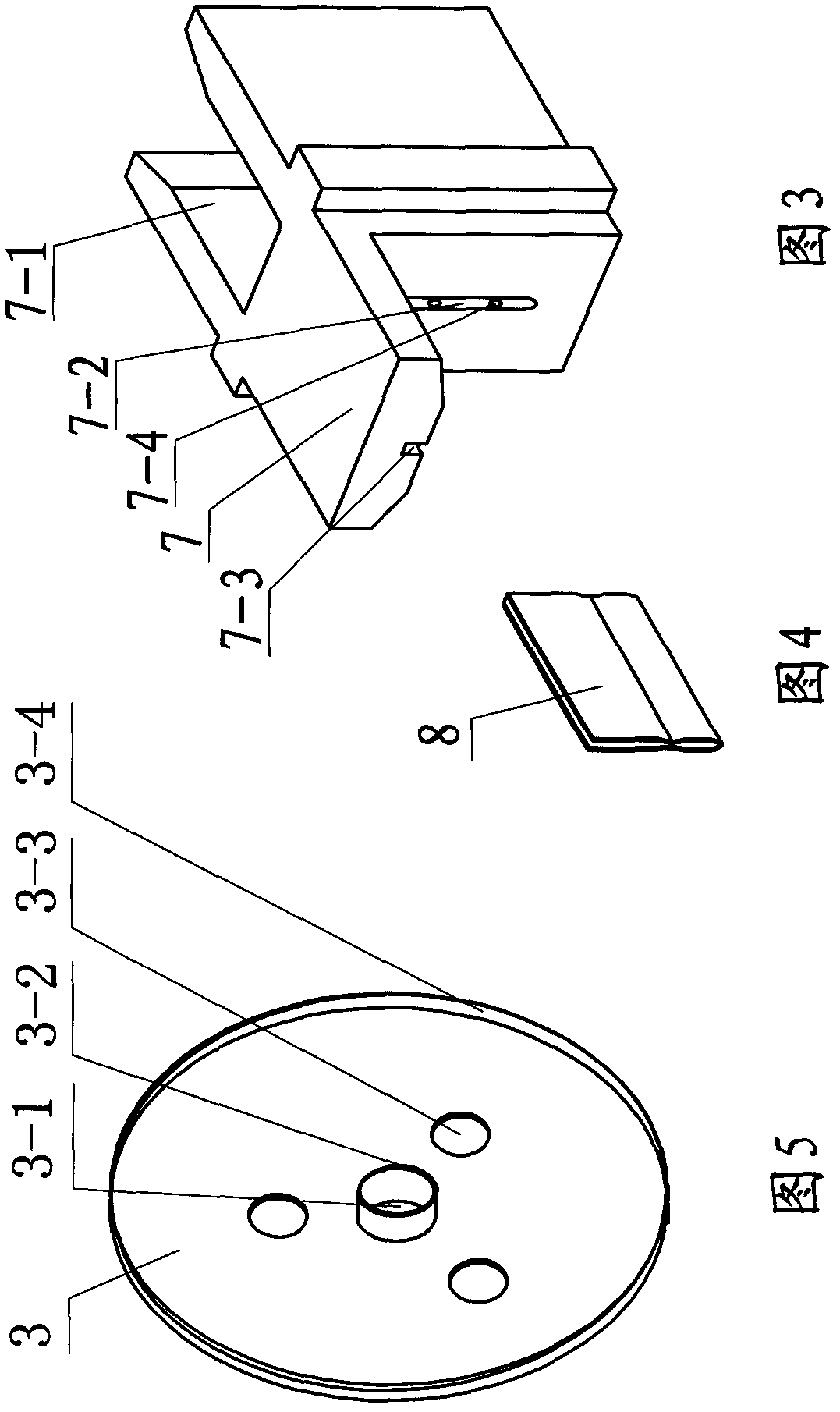

[0013] The supporting piece 3 is a whole disc shape, made of bright metal or stainless steel. There is a supporting hole 3-1 in the middle. The hole edge has a hole flanging 3-2 in the same direction as the flanging 5, and the supporting hole edges are evenly distributed. The expansion hole 3-3 facilitates the thermal expansion and contraction of the material without deformation. There are flanges 3-4 perpendicular to the wafer and smooth surface around the support sheet to increase the mechanical strength of the support sheet, such as Figure 5 Shown.

[0014] The clip 8 is made of stainless steel and has indentations on both surfaces, such as Figure 4 Shown.

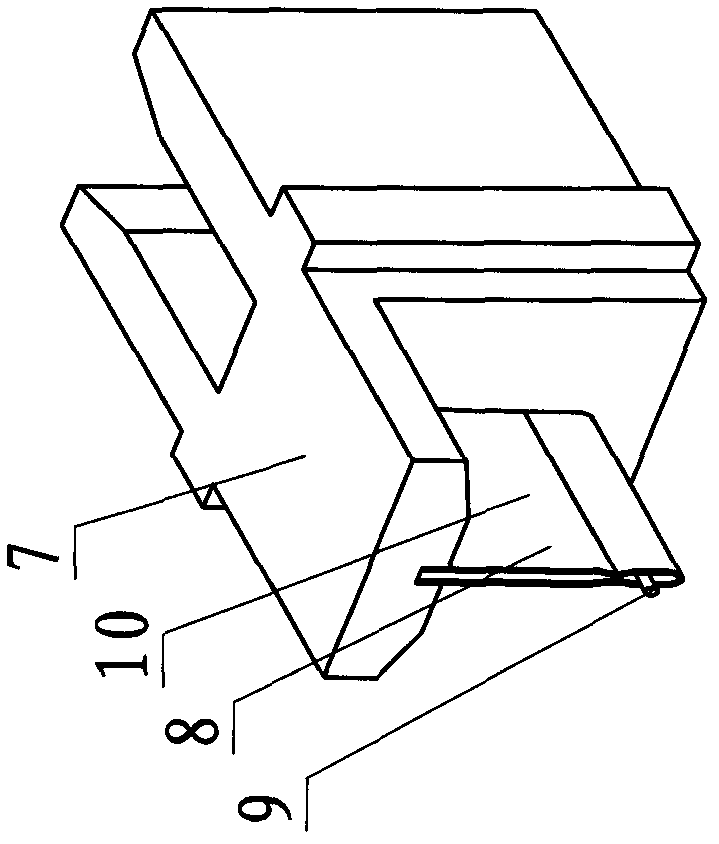

[0015] Porcelain head 7 is made of insulating material with temperature resistance, humidity resistance and high dielectric strength. There is a short groove 7-2 on the left vertical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com