Wheat conditioning and sterilizing method

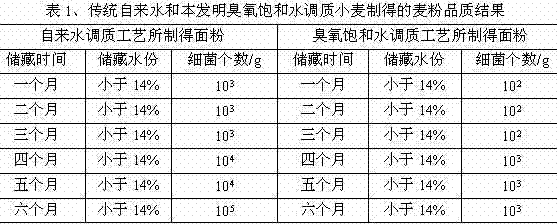

A sterilization method and technology for wheat, applied in grain processing, food preparation, grain milling, etc., can solve the problems of easy mildew, short flour storage period, increased bacterial content of wheat flour, etc., and achieve no harmful residues, No secondary pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A wheat conditioning and sterilization method, adding 4% water (the water content of the original wheat is 12%) to the raw wheat after impurity removal, so that the water content in the wheat is kept at 16%, and then sent to the wheat moistening warehouse for 28 hours to moisten Wheat is then sent to the secondary conditioning bin, where 0.5% of the wheat’s weight of ozone-saturated water is added by spraying water, and then placed for 1 hour and sent to the subsequent grinding and milling system (including five skin mills, two slag mills, seven Heart milling, two-stage tail milling, ten-stage flour clearing, impact-assisted flour extraction, and back-stage bran beating; this process flow is a conventional technology in the field, so it will not be described in detail) to obtain flour.

Embodiment 2

[0018] A wheat conditioning and sterilization method, adding 5% water to the raw wheat after impurity removal (the water content of the original wheat is 10%) to keep the water content in the wheat at 15%, and then sending it to the wheat moistening warehouse for 36 hours to moisten Wheat, then sent to the secondary tempering bin, adding ozone-saturated water accounting for 1.0% of the wheat weight by spraying water, and then placed for 1.5h and sent to the subsequent grinding and milling system (including five skin mills, two slag mills, Seven-way heart mill, two-way tail mill, ten-way powder clearing, impact-assisted flour extraction, and back-road bran beating; this process flow is a conventional technology in this field, so it will not be described in detail) to obtain flour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com