Single-direction inclined-shaft profiling precision grinding method of array optical elements of micro circular troughs

A technology for optical components and precision grinding, which is applied in the direction of optical surface grinders, grinding/polishing equipment, grinding machines, etc. It can solve the problems of low grinding efficiency, easy wear of grinding wheels, and large difference in surface roughness, etc., to achieve grinding The effect of improving machining efficiency, improving machining accuracy, and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

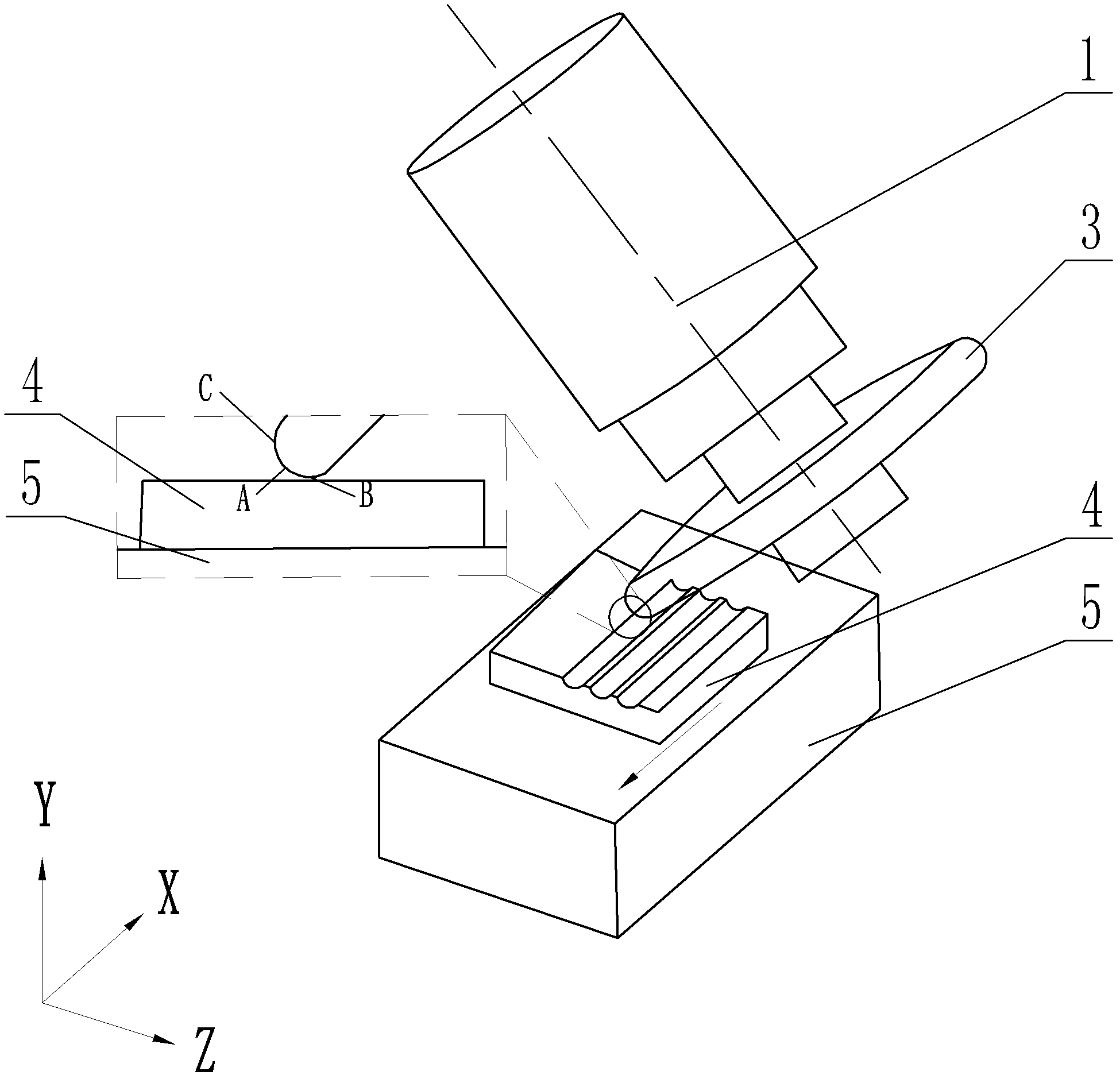

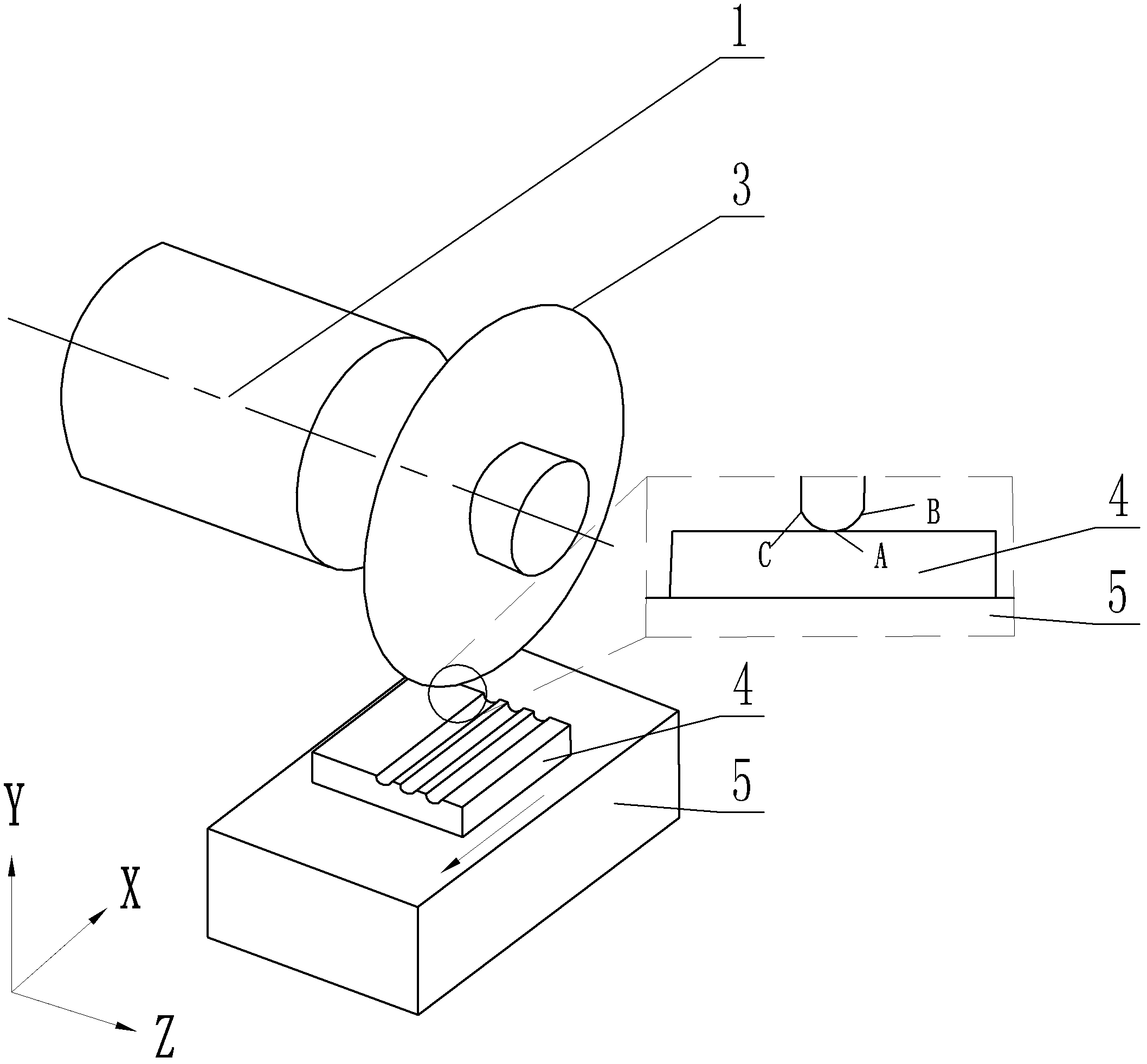

[0014] Specific implementation mode one: combine figure 1 Explain that the single-direction oblique-axis profiling precision grinding method of the micro-arc groove array optical element described in this embodiment is realized according to the following steps:

[0015] Step 1. Fix the workpiece 4 to be ground on the upper surface of the workbench 5 of the precision grinding machine, and rotate the profiling grinding wheel 3 so that the rotation axis 1 of the profiling grinding wheel 3 forms an angle of 45 degrees with the plane where the surface of the workpiece 4 to be ground is located, so that The first lowest point B of the profiling grinding wheel 3 becomes the grinding center point;

[0016] Step 2. Adjust the profiling grinding wheel 3 to the initial point of the first arc groove to be processed, so that the workpiece 4 to be ground is fed in the opposite direction of the X axis along with the precision grinding machine table 5, and the rotation direction of the profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com