Drilling machine

A drilling machine and frame technology, applied in the field of mechanical processing, can solve the problems of no drilling machine installation, energy waste, and increased processing costs of cylinders, etc., and achieve the effects of improving production and manufacturing efficiency, reducing air pollution, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

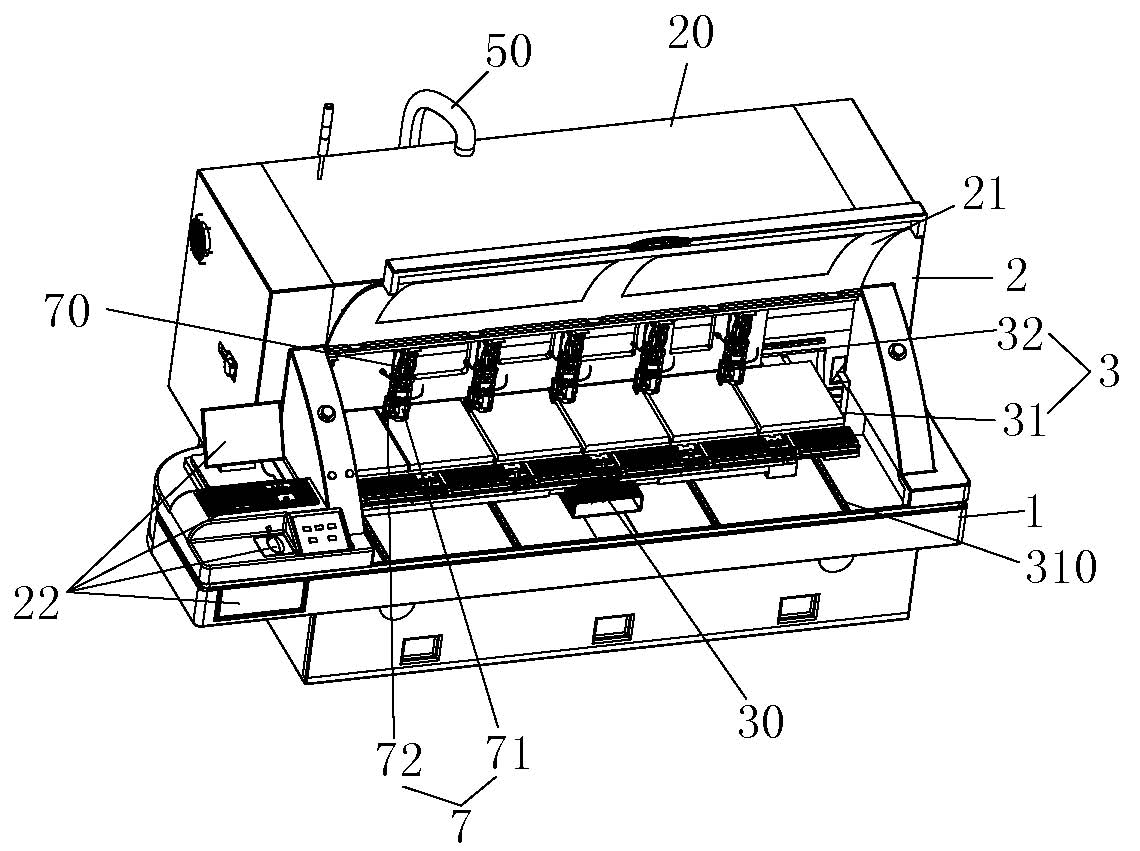

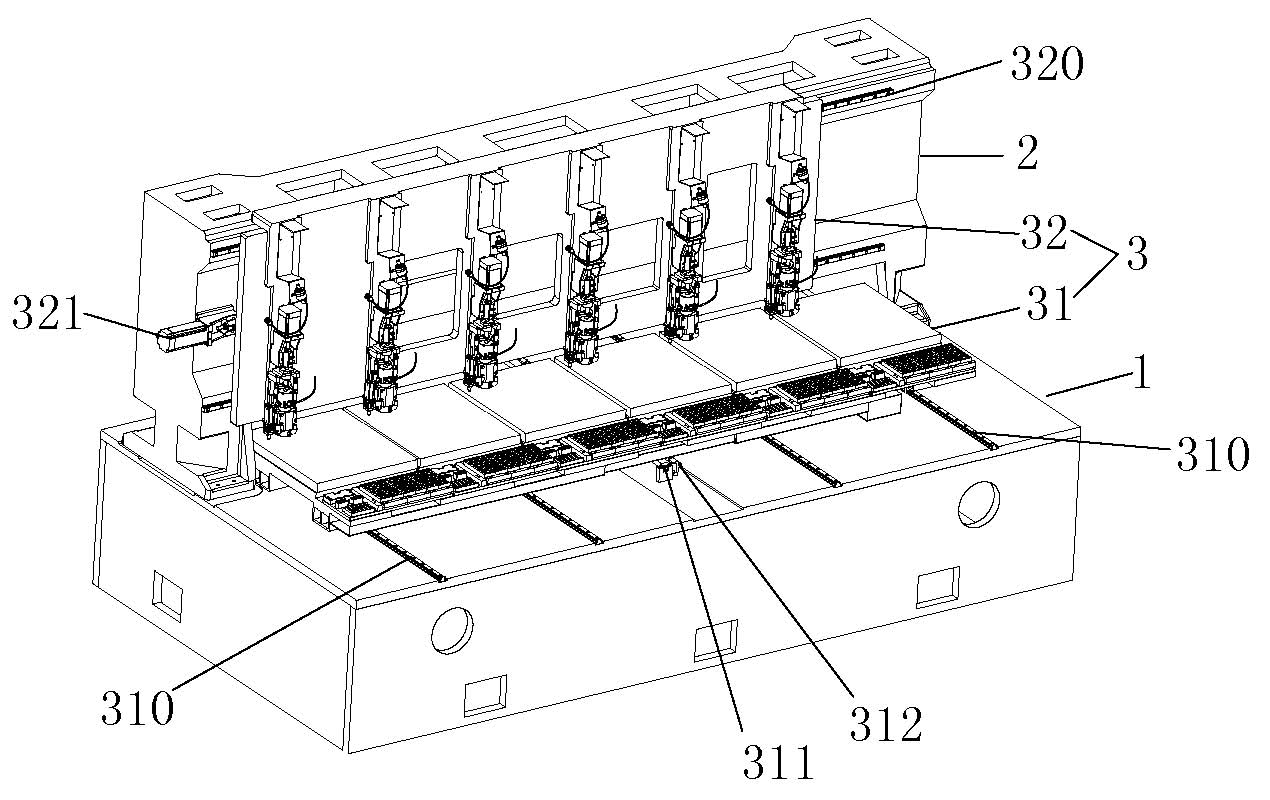

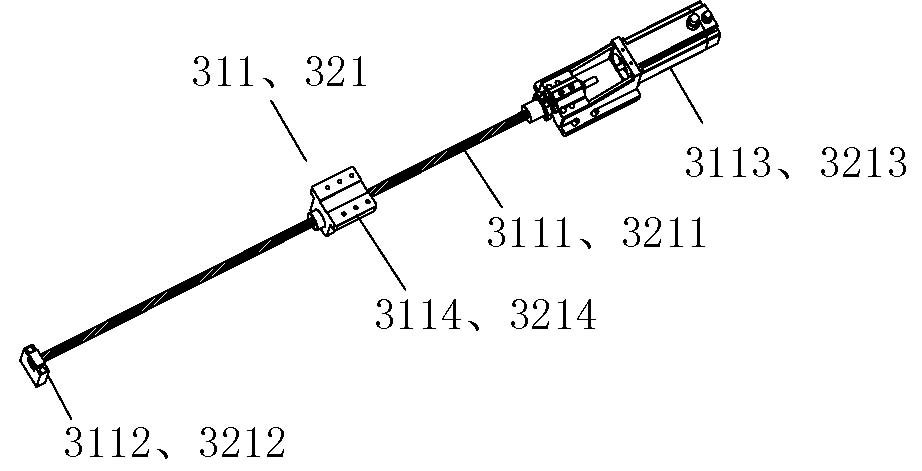

[0047] A kind of drilling machine, it is characterized in that: it comprises: a machine platform 1, this machine platform 1 is used as the carrying device of whole drilling machine; A frame 2, this frame 2 is installed on the machine platform 1; A mobile platform 3, It includes: an X-axis platform 31 installed on the machine 1 and a Y-axis platform 32 installed on the frame 2; a broken knife detection mechanism 4, which is fixedly installed on the frame 2 through its housing 41 Above; a powder suction device 5, the powder suction device 5 is installed on the side of the frame 2, and communicates with the housing 41 of the broken knife detection device 4 through a small dust suction tube 50; an oil cooling device 6, the oil cooling The device 6 is installed on the side of the frame 2; at least six manipulator devices 7 are installed on the frame 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com