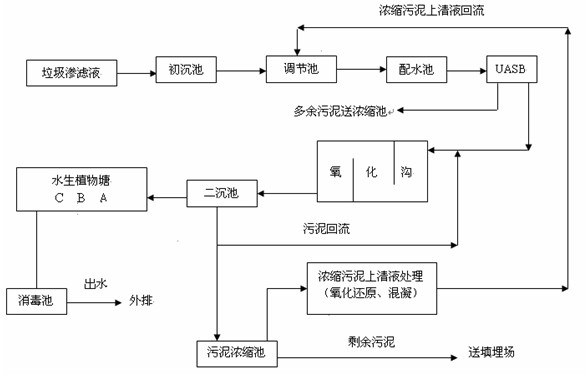

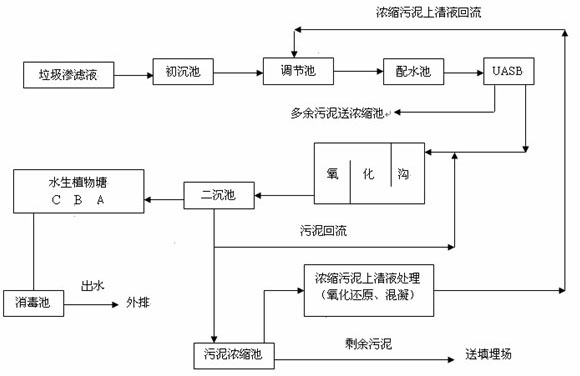

Landfill leachate treatment process

A technology of landfill leachate and treatment process, applied in the field of high-concentration organic wastewater treatment, can solve the problem that the treatment process cannot meet the national sewage discharge standard and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: this landfill leachate treatment process, concrete operation is as follows:

[0028] (1) Collect the landfill leachate and enter the primary sedimentation tank for sedimentation, so that most of the impurities and sludge in it are precipitated, and then the sewage enters the adjustment tank for 5 days to adjust the water quality and water quantity.

[0029] (2) Pump the landfill leachate from the adjustment tank into the distribution tank, and then distribute the water through the distribution tank into the upflow anaerobic sludge bed (UASB) reactor for anaerobic reaction, and the generated biogas, sewage and sludge pass through The three-phase separator on the upper part of the anaerobic reactor is separated, the biogas is discharged through the gas collection chamber, the sewage containing sludge enters the settling area, and the sludge with good settling performance settles to the sludge bed of the anaerobic reactor, and the sewage containing a small amo...

Embodiment 2

[0036] Embodiment 2: this landfill leachate treatment process, concrete operation is as follows:

[0037] (1) Collect the landfill leachate and enter the primary sedimentation tank for sedimentation, so that most of the impurities and sludge in it are precipitated, and then the sewage enters the adjustment tank for 10 days to adjust the water quality and water quantity.

[0038] (2) Pump the landfill leachate from the adjustment tank into the distribution tank, and then distribute the water through the distribution tank into the upflow anaerobic sludge bed (UASB) reactor for anaerobic reaction, and the generated biogas, sewage and sludge pass through The three-phase separator on the upper part of the anaerobic reactor is separated, the biogas is discharged through the gas collection chamber, the sewage containing sludge enters the settling area, and the sludge with good settling performance settles to the sludge bed of the anaerobic reactor, and the sewage containing a small am...

Embodiment 3

[0046] Embodiment 3: this landfill leachate treatment process, concrete operation is as follows:

[0047] (1) Collect the landfill leachate and enter the primary sedimentation tank for sedimentation, so that most of the impurities and sludge in it are precipitated, and then the sewage enters the adjustment tank for 8 days to adjust the water quality and water quantity.

[0048] (2) Pump the landfill leachate from the adjustment tank into the distribution tank, and then distribute the water through the distribution tank into the upflow anaerobic sludge bed (UASB) reactor for anaerobic reaction, and the generated biogas, sewage and sludge pass through The three-phase separator on the upper part of the anaerobic reactor is separated, the biogas is discharged through the gas collection chamber, the sewage containing sludge enters the settling area, and the sludge with good settling performance settles to the sludge bed of the anaerobic reactor, and the sewage containing a small amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com