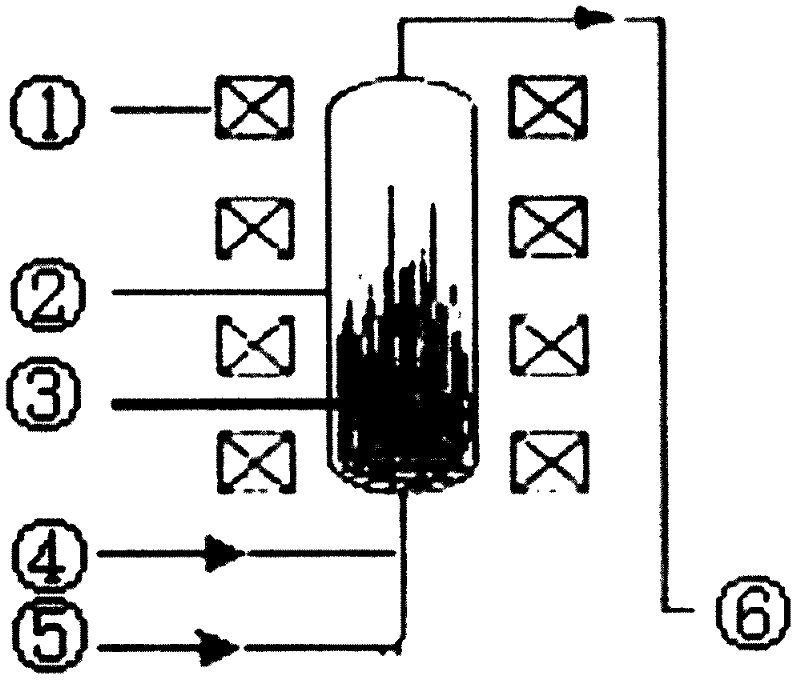

Method for preparing cyclohexene by selectively hydrogenising benzene in magnetic stabilization bed

A technology of selective hydrogenation and magnetically stabilized bed, applied in the fields of hydrogenation to hydrocarbons, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Hexene cannot be separated out in time, so as to improve the selectivity and yield, reduce the loss and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) The coercive force of the magnetic catalyst carrier is 2kA / m, and the specific saturation magnetization is 10Am 2 / kg, the magnetic core is Fe 3 o 4 , the magnetic core size is 1 μm, and the cladding layer is γ-Al 2 o 3 The thickness of the cladding layer is 20μm, the mass fraction of the magnetic core is 20%, and 0.01mol / L RuCl is configured 3 Aqueous solution, and add additive ZnCl 2 aqueous solution, the molar ratio of Ru to metal ions in the auxiliary agent is 5:1, the magnetic catalyst carrier is immersed in the above mixed solution for 3 hours, and then 0.5mol / L NaBH is added dropwise 4 Aqueous solution, control NaBH 4 mixed with solution metal ions Ru 3+ , Zn 2+ The molar ratio is 10:1 to ensure that the metal cations are completely reduced, so that the loading of Ru is 2wt%, and then the magnetic catalyst is washed with deionized water to neutrality, and then washed three times with absolute ethanol, and finally the catalyst sample is stored in Preven...

Embodiment 2

[0019] 1) The coercive force of the magnetic catalyst carrier is 20kA / m, and the specific saturation magnetization is 15Am 2 / kg, the magnetic core is γ-Fe 2 o 3 , the magnetic core size is 5 μm, and the cladding layer is γ-Al 2 o 3 The thickness of the cladding layer is 50 μm, the mass fraction of the magnetic core is 10%, and 0.05mol / L RuCl is configured 3 Aqueous solution, and add additive ZnCl 2 aqueous solution, the molar ratio of Ru to metal ions in the additive is 8:1, the magnetic catalyst carrier is immersed in the above mixed solution for 2 hours, and then 0.5mol / L NaBH is added dropwise 4 Aqueous solution, control NaBH 4 mixed with solution metal ions Ru 3+ , Zn 2+ The molar ratio is 20:1 to ensure that the metal cations are completely reduced, so that the loading of Ru is 5wt%, then the magnetic catalyst is washed with deionized water to neutrality, and then washed three times with absolute ethanol, and finally the catalyst sample is stored in Prevent oxida...

Embodiment 3

[0023] 1) The coercive force of the magnetic catalyst carrier is 10kA / m, and the specific saturation magnetization is 12Am 2 / kg, the magnetic core is Fe 3 o 4 , the magnetic core size is 3 μm, and the cladding layer is γ-Al 2 o 3 The thickness of the cladding layer is 100 μm, the mass fraction of the magnetic core is 40%, and 0.01mol / L RuCl is configured 3 Aqueous solution, and add additive ZnSO 4 aqueous solution, the molar ratio of Ru to metal ions in the auxiliary agent is 10:1, the magnetic catalyst carrier is immersed in the above mixed solution for 3 hours, and then 1mol / L NaBH is added dropwise 4 Aqueous solution, control NaBH 4 mixed with solution metal ions Ru 3+ , Zn 2+ The molar ratio is 15:1 to ensure that the metal cations are completely reduced, so that the loading of Ru is 3wt%, then the magnetic catalyst is washed with deionized water to neutrality, and then washed three times with absolute ethanol, and finally the catalyst sample is stored in Prevent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com