Efficient online automatic cutting machine

A cutting machine and automatic technology, used in textiles and papermaking, papermaking, fiberboard, etc., can solve the problems of material insecurity, reduced product yield, wasted time, etc., and achieve low production safety hazards, easy operation, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

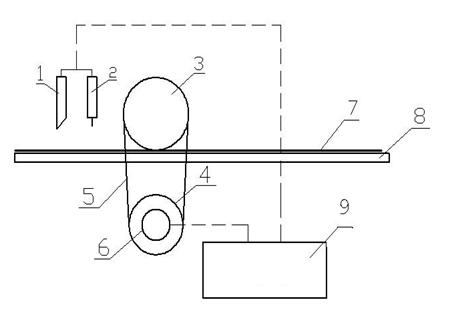

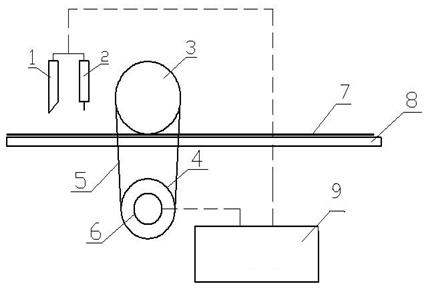

[0014] A high-efficiency online automatic cutting machine, including: strip knife 1, sensor 2 inside the roller, roller 3, stepping motor gear 4, synchronous chain 5, stepping motor 6, glass wool board 7, workbench 8 and control system 9; the roller 3 is installed above the workbench 8, and the stepper motor 6 drives the roller 3 to pass through the synchronous chain 5; the sensor 2 inside the strip knife 1 and the roller is located at the front end of the roller 1; the control system 9 controls the start and close of the stepper motor 6 .

[0015] The production process of the efficient online automatic cutting machine described in the present embodiment is as follows:

[0016] Open the control system 9, input the required length and width of the glass wool board to the control system 9, set the transmission speed of the glass wool board at the same time, and start the operation. The glass wool board 7 is conveyed on the workbench 8. The glass wool board enters the cutter wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com