Non-load crack prevention method for layered pouring of zero block web plate

A technology of layered pouring and prevention method, applied in construction, bridge construction, bridges, etc., can solve the problem of no prevention/avoidance measures, and achieve the effect of preventing cracks, reducing temperature rise, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

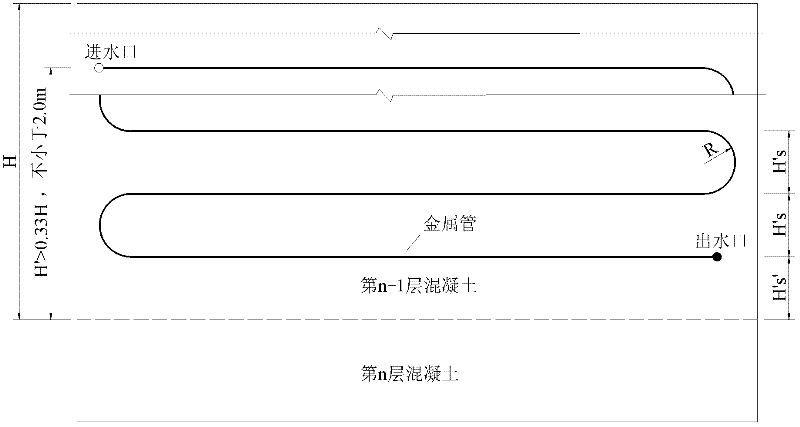

[0033] As shown in the accompanying drawings, the non-load crack prevention method of the zero block web layered pouring of the present invention is to pre-embed thick-walled metal pipes in the upper concrete of the zero block web layered layered pouring, and the method includes the following successively step:

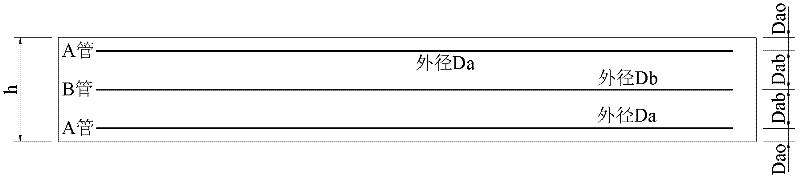

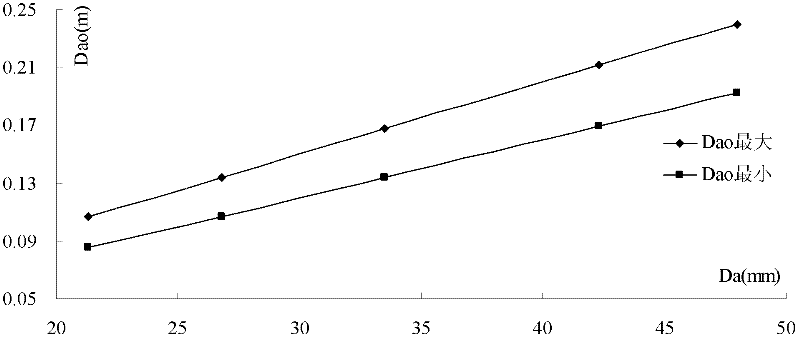

[0034] Step 1: Prepare cooling pipes of corresponding specifications according to the web thickness, including A cooling pipe and B cooling pipe. Cooling tubes with a thickness of 3.0mm, of which the outer diameter of cooling tube A is 42.3mm, and the outer diameter of cooling tube B is 48.0mm.

[0035] Step 2: After the first layer of concrete pouring is completed, after 2 days of curing, start to bind the second layer of steel bars and install the formwork, then bend the cooling pipe in the longitudinal direction to make it return to the shape and fix it on the steel bar, and the cooling pipe needs to be arranged vertically The height of the cooling pipe on the bot...

Embodiment 2

[0040] As shown in the accompanying drawings, the non-load crack prevention method of the zero block web layered pouring of the present invention is to pre-embed thick-walled metal pipes in the upper concrete of the zero block web layered layered pouring, and the method includes the following successively step:

[0041]Step 1: Prepare cooling pipes of corresponding specifications according to the web thickness, including A cooling pipe and B cooling pipe. The diameter is 48.0mm, the wall thickness is 3.0mm, the outer diameter of B cooling tube is 60.0mm, and the wall thickness is 5.0mm.

[0042] Step 2: After the first layer of concrete pouring is completed, after 2 days of curing, start to bind the second layer of steel bars and install the formwork, then bend the cooling pipe in the longitudinal direction to make it return to the shape and fix it on the steel bar, and the cooling pipe needs to be arranged vertically The height of the cooling pipe is 2.70m, the distance betw...

Embodiment 3

[0047] As shown in the accompanying drawings, the non-load crack prevention method of the zero block web layered pouring of the present invention is to pre-embed thick-walled metal pipes in the upper concrete of the zero block web layered layered pouring, and the method includes the following successively step:

[0048] Step 1: Prepare cooling pipes of corresponding specifications according to the web thickness, including A cooling pipe and B cooling pipe. The diameter is 33.5mm, the wall thickness is 3.0mm, the outer diameter of B cooling tube is 33.5mm, and the wall thickness is 4.0mm.

[0049] Step 2: After the first layer of concrete pouring is completed, after 2 days of curing, start to bind the second layer of steel bars and install the formwork, then bend the cooling pipe in the longitudinal direction to make it return to the shape and fix it on the steel bar, and the cooling pipe needs to be arranged vertically The height of the cooling pipe on the bottom layer is 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com