Prefab house made of autoclaved aerated concrete slabs and assembly method for prefab house

A technology of autoclaved and aerated prefabricated houses, which is applied in the direction of residential buildings, buildings, building structures, etc., and can solve the problems of easy damage of boards, poor thermal insulation performance, fireproof performance, sound insulation and impact resistance, and repeated use. Low efficiency and other problems, to improve sound insulation and impact resistance, meet the effect of repeated use, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The assembly method of the autoclaved aerated concrete slab prefabricated house of the present invention comprises the following steps:

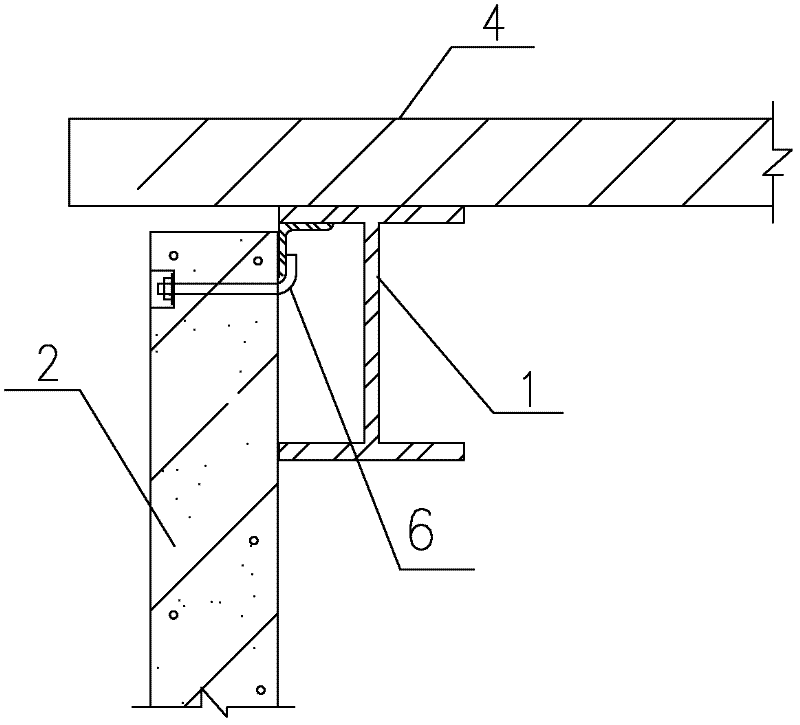

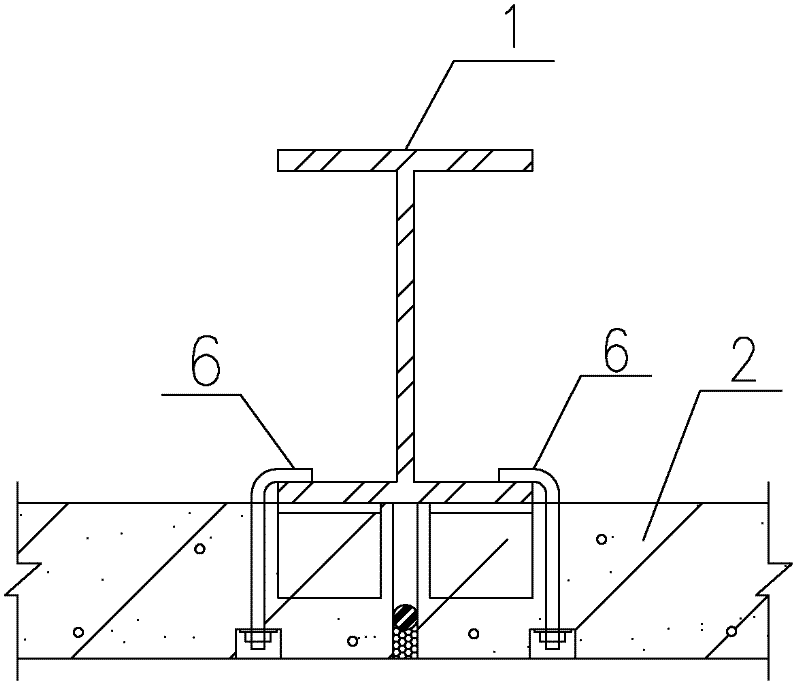

[0033] The first step is to install the steel frame 1 of the prefabricated house. The steel frame includes steel columns and main beams. You can choose square tubes with specifications of 100mm×100mm×8mm, 150mm×150mm×6mm or 200mm×150mm×3.2mm× 4.5mm, 250mm×150mm×3.2mm×4.5mm H-shaped steel, the specific specifications can be designed separately according to the size of the room and the number of floors. For the convenience of disassembly, after the specifications and sizes of all components are designed, they can be assembled with bolts during construction;

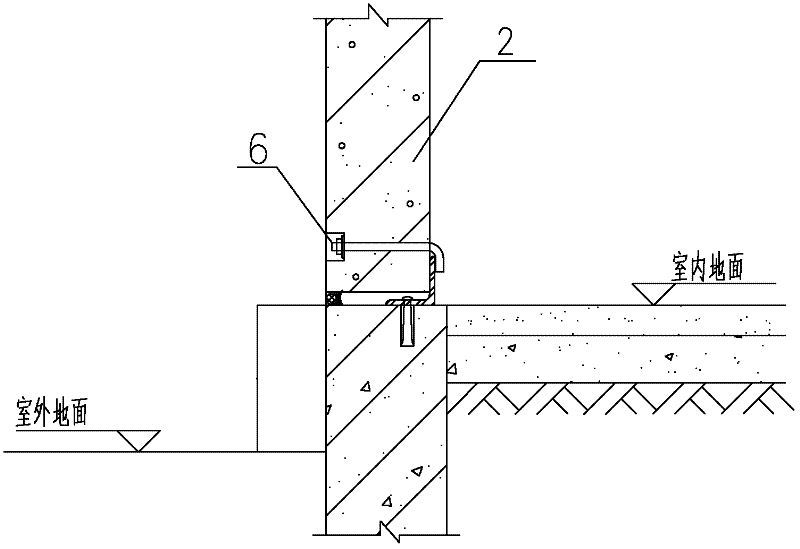

[0034] The second step is to install the exterior wall panel 2 of autoclaved aerated concrete, which can be installed horizontally (horizontally installed, that is, the surface formed by the side in the length direction of the panel and the side in the width direction is perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com