Multistage filtering and drainage system for deep-long water-rich tunnel underground water and construction method thereof

A water-rich tunnel and drainage system technology, applied in the direction of tunnel, drainage, earthwork drilling and mining, etc., can solve the difficulty of dredging work, cannot effectively remove the accumulated water on the tunnel ground, and cannot meet the requirements of dredging, etc. Problems, to achieve the effect of good sewage recycling on-site recycling, good sedimentation and filtration effect, and improved sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

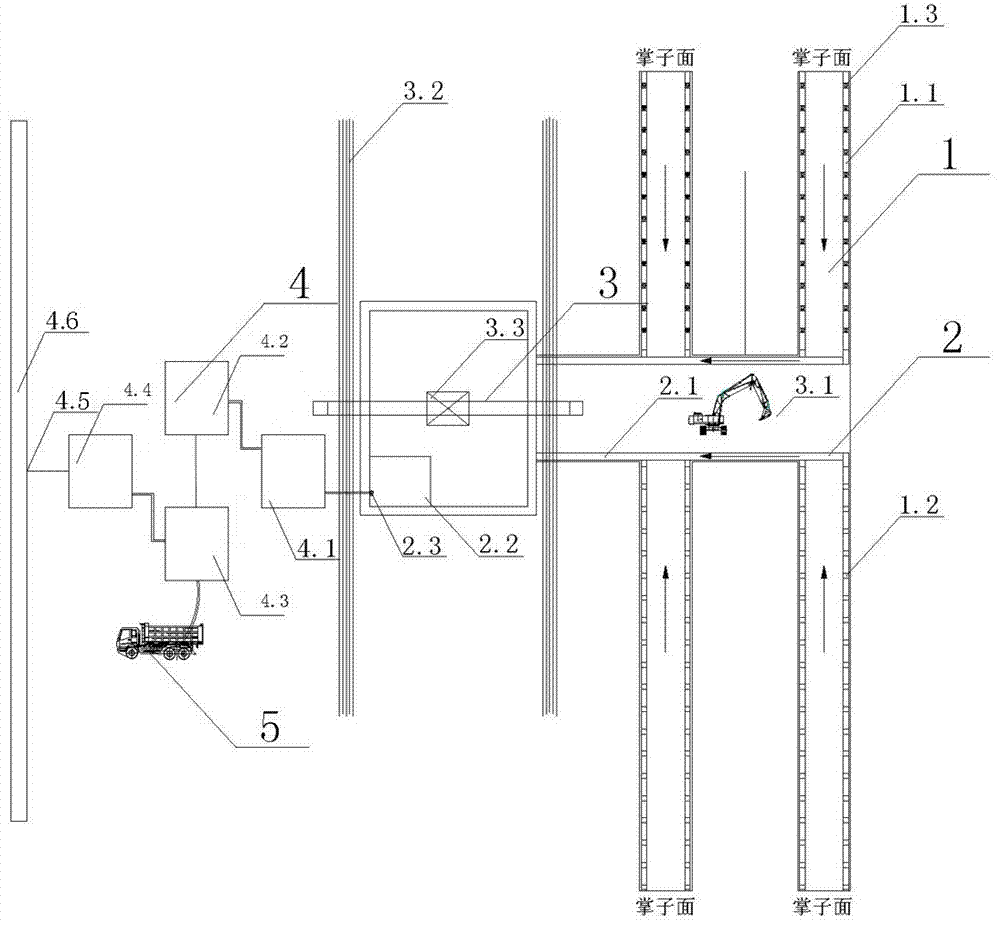

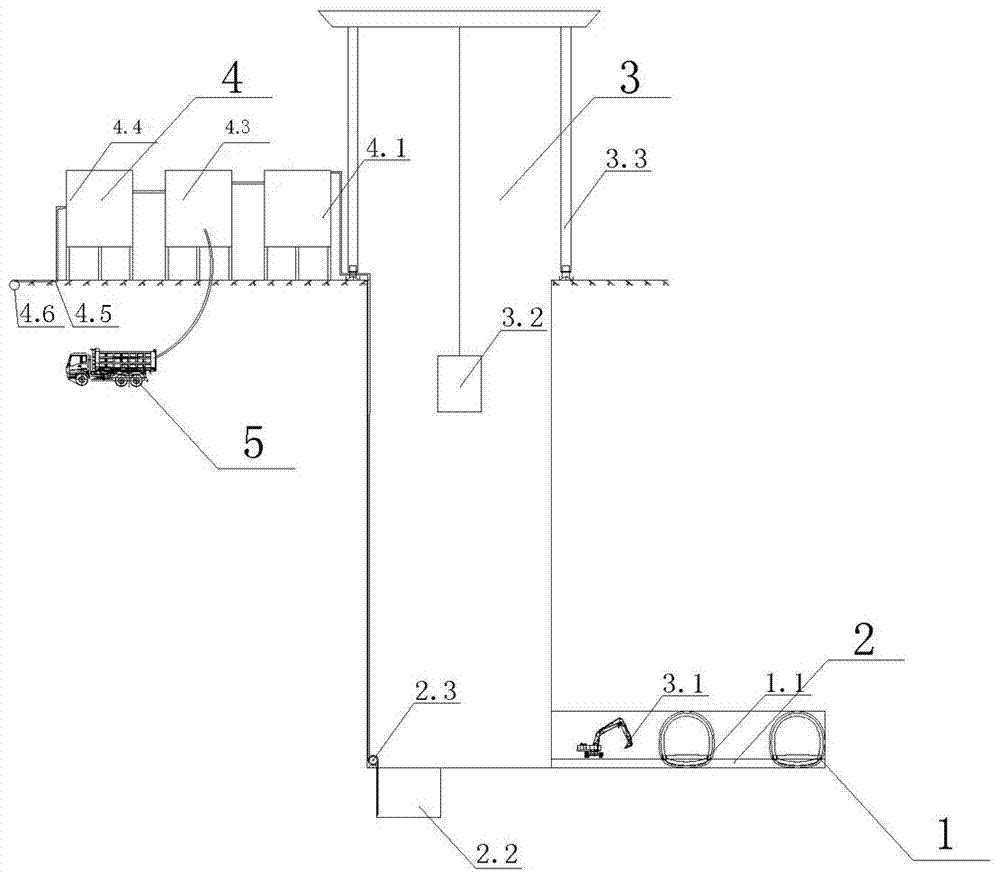

[0043] like Figure 1 to Figure 5 As shown, a deep and long-distance water-rich tunnel groundwater multi-stage filtration and drainage system includes a gantry crane 3.2 and a lifting slag bucket 3.3, wherein:

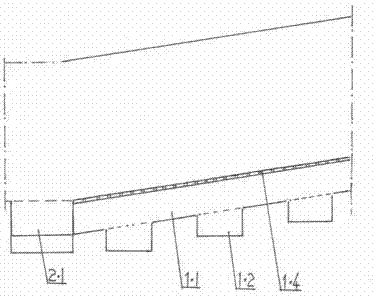

[0044] Tunnel drainage and sedimentation system 1: including tunnel drainage ditch 1.1, drainage ditch sedimentation tank 1.2 and step-by-step turning pump 1.3. The cross-sectional shape of the tunnel drainage ditch is rectangular, and it is used to introduce the groundwater from the face of the tunnel excavation to the cross passage ditch 2.1, which is made of brick masonry or concrete pouring. The upper end surface of the tunnel drainage ditch is provided with a perforated cement cover plate 1.4, which can be used as a road for workers to enter and exit.

[0045] The tunnel drainage ditch is located on both sides or in the middle of the ground of the working tunnel. The lower bottom surface of the tunnel drainage ditch is provided with a drainage ditch sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com