Construction method of shotcrete support for water contained loess geological tunnel

A technology of shotcrete and construction method, which is applied in underground chambers, earthwork drilling, shaft equipment, etc., to achieve the effects of preventing overall subsidence, ensuring durability, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

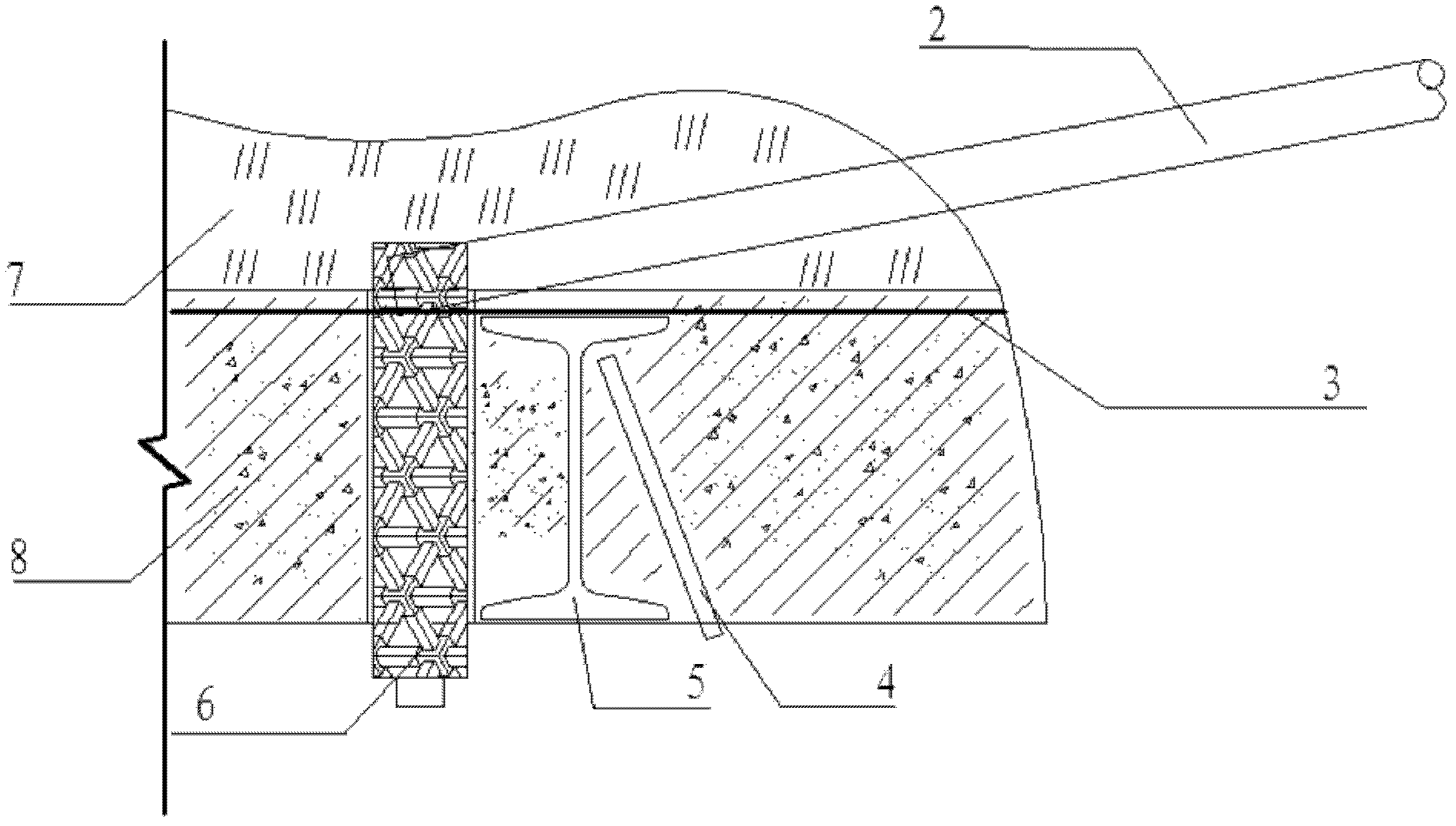

[0031] A. Carry out the pipe shed construction step on the said cave body, install a steel arch frame under the pipe shed position after construction, drill a number of pipe shed pipe holes at the pipe shed position, and punch a number of pipe shed pipe holes on the pipe shed pipe wall in advance. Small holes, and the pipe shed pipe filled with water-absorbing agent is inserted into the pipe hole, and the end of the pipe shed pipe is welded with the steel arch frame. For each construction of 5-9 steel arch frames, a group of pipe shed pipes is constructed. Form the upper arch excavation temporary support stress system;

[0032] The pipe shed method or the umbrella arch method is a super-strong support structure for shallow buried underground excavation in underground structural engineering. Its essence is to pre-drill holes and install thick-walled steel pipes with large moments of inertia on the buried arc of the lining arch ring of the underground tunnel to be excavated or s...

Embodiment 2

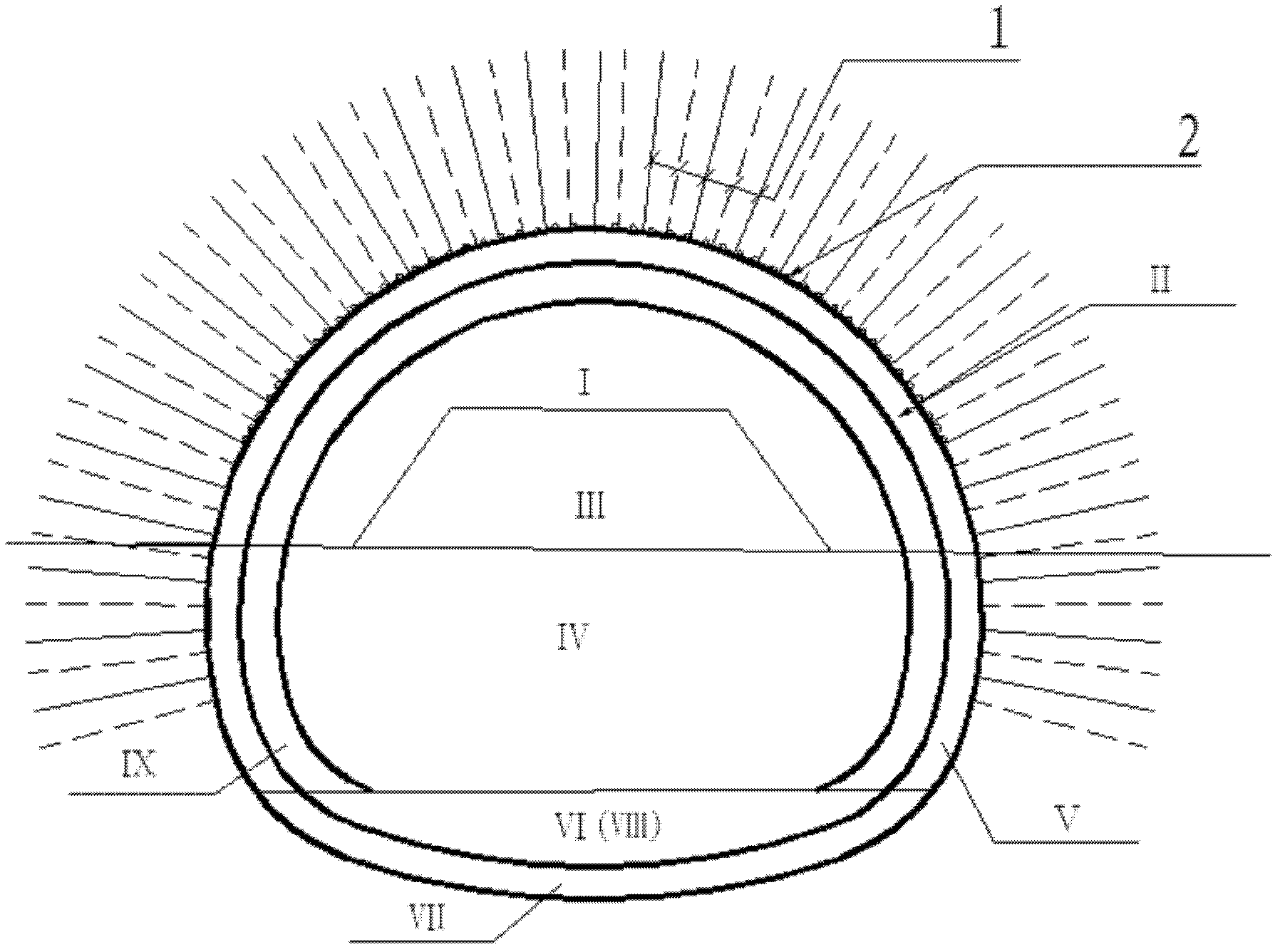

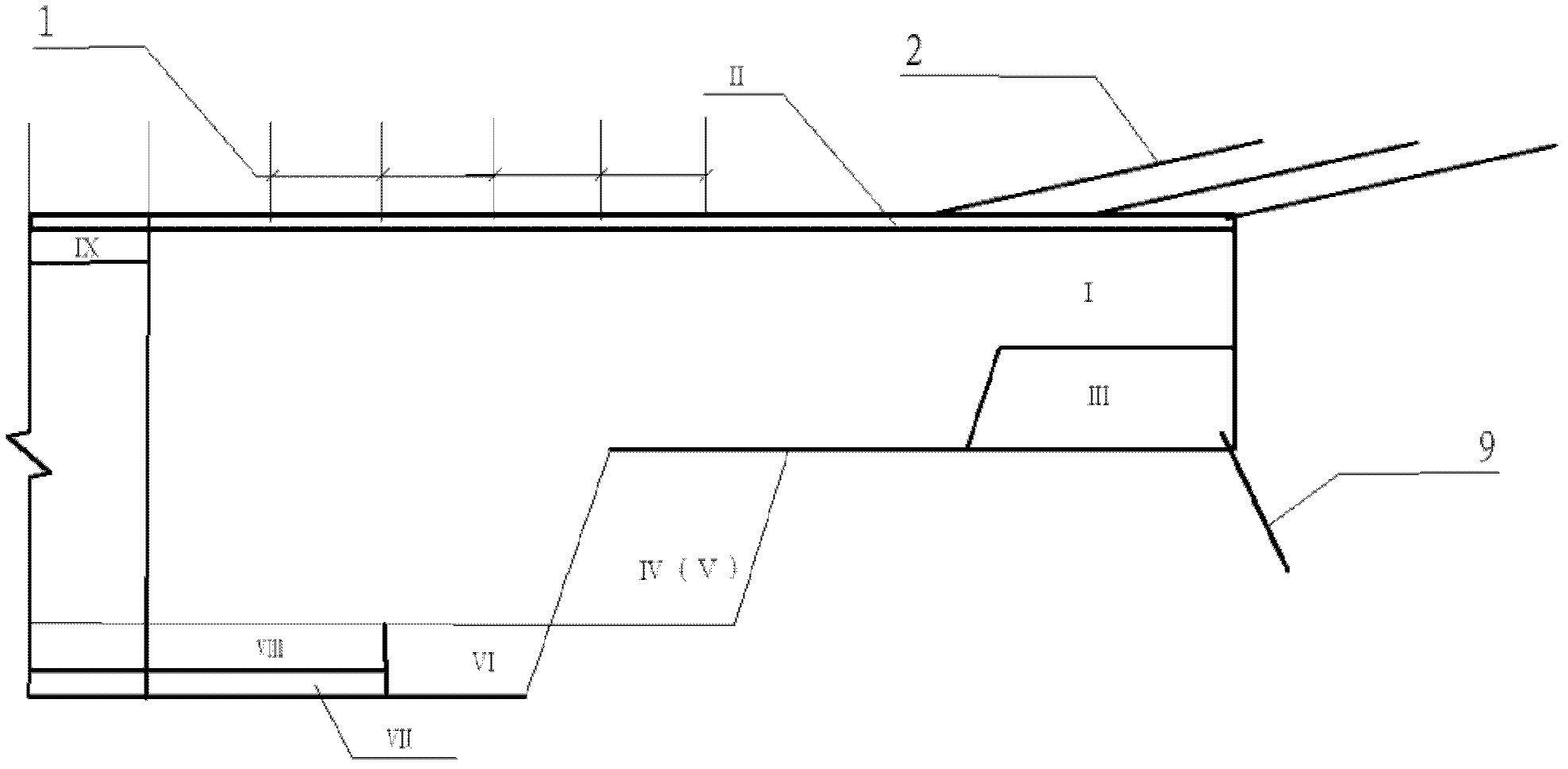

[0051] Embodiment two, such as Figure 1~4 Shown:

[0052] I. The excavation of the upper arc-shaped pilot pit is generally 0.5m, and the initial support of the arch should be constructed in time;

[0053] II. The arch is hung with steel mesh, the steel arch frame is erected, and the concrete is first sprayed;

[0054] III. Excavate the core soil, install the system anchor rod, and spray the concrete twice to the standard;

[0055] IV. Waist excavation (excavation at the left and right vaults, length 2-3m);

[0056] V. The waist arch wall is hung with steel mesh, the steel arch frame is erected, and the anchor is shotcrete;

[0057] VI. Inverted arch excavation (excavation at the left and right vaults, length 2-3m);

[0058] VII. The inverted arch is hung with steel mesh, the steel arch frame is erected, and the concrete is sprayed;

[0059] VIII, inverted arch filling, concrete molding;

[0060] IX. The secondary concrete molded lining of the arch wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com