Motor-AMT (automated mechanical transmission) coupling mechanism

A coupling mechanism and motor shaft technology, applied in the field of electric vehicles, can solve the problems of increasing cost, increasing front cabin space, increasing the weight of electric vehicles, etc., to achieve the effect of saving space and improving cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

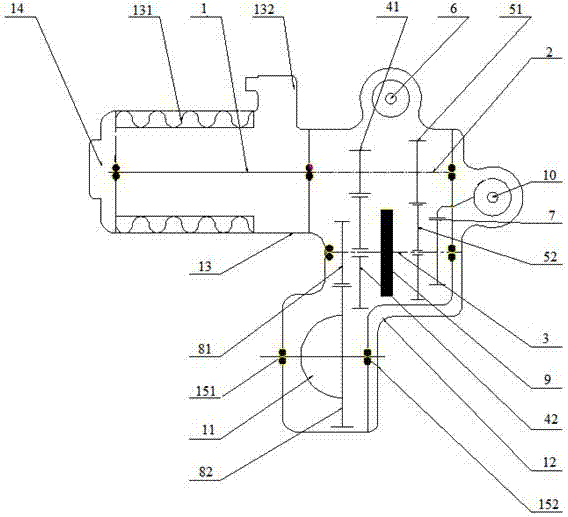

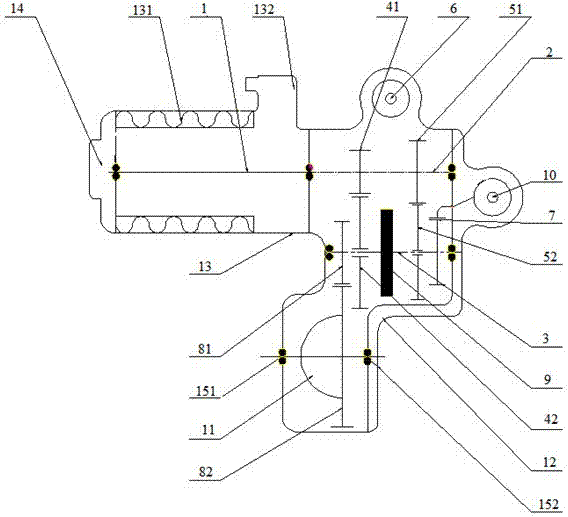

[0013] Below with reference to the accompanying drawings, through the description of the implementation examples, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the role and working principle of each part, etc., will be further described. detailed instructions.

[0014] Such as figure 1 , the motor-AMT coupling mechanism of the present invention includes a motor body (not shown in the figure), a motor shaft 1, an AMT input shaft 2, an AMT output shaft 3, a first gear driving wheel 41, a second gear driving wheel 51, a first gear slave The driving wheel 42, the second gear driven wheel 52, the shift controller 6, the parking wheel 7, the driving gear 81, the driving gear 82, the synchronizer mechanism 9, the parking assembly 10 and the differential case 11, The first gear driving wheel 41 and the second gear driving wheel 51 are fixed on the AMT input shaft 2 by splines to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com