Ceramic radiator for high-power light-emitting diode (LED) module or lamp and manufacturing process for ceramic radiator

A LED module and high-power technology, which is applied in semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of low molding yield, card mold damage, and low yield. Achieve the effect of improving heat dissipation efficiency, low mold opening cost and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

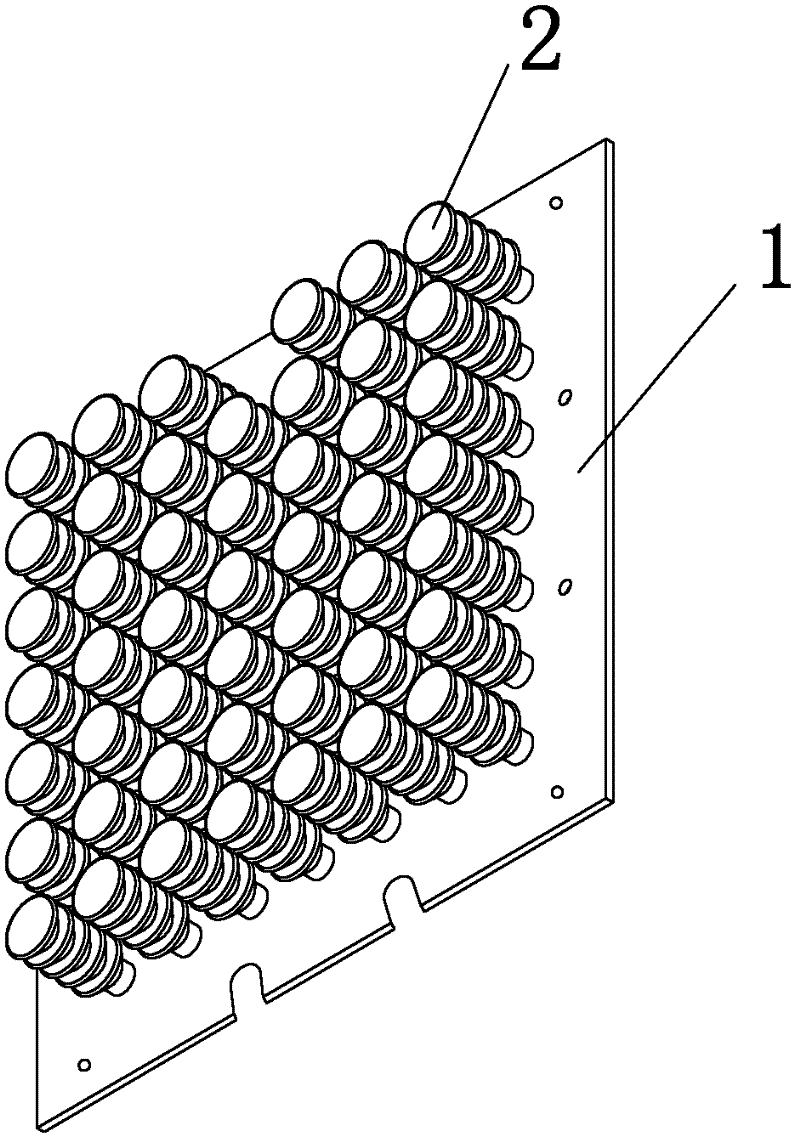

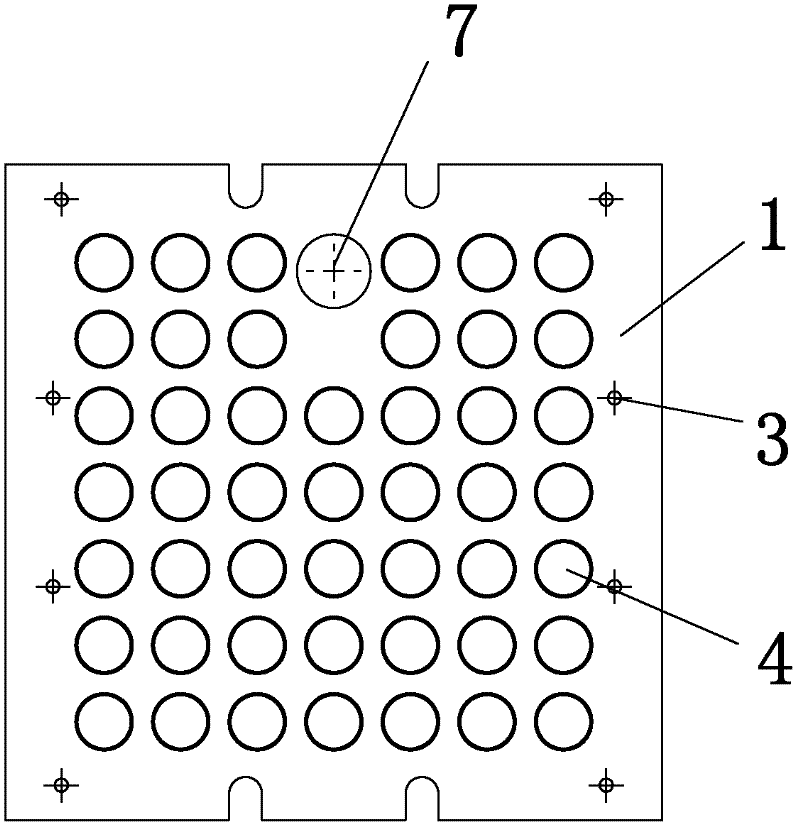

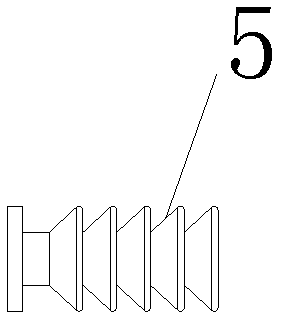

[0020] As shown in the accompanying drawings, the present invention includes a ceramic heat dissipation bottom plate 1 and a ceramic heat dissipation column 2. Several impermeable blind holes 4 are opened on the upper surface of the ceramic heat dissipation bottom plate 1, and ceramic heat dissipation columns are installed in the blind holes 4. 2. The ceramic heat dissipation bottom plate 1 is provided with a plurality of screw holes and outlet holes, and the outer surface of the ceramic heat dissipation column 2 is provided with a plurality of heat dissipation grooves 5 .

[0021] Manufacturing process of the present invention comprises the steps:

[0022] The first stage (mold opening stage): the ceramic heat dissipation bottom plate 1 and the ceramic heat dissipation column 2 are molded separately; mold one: the ceramic heat dissipation bottom plate: a flat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com