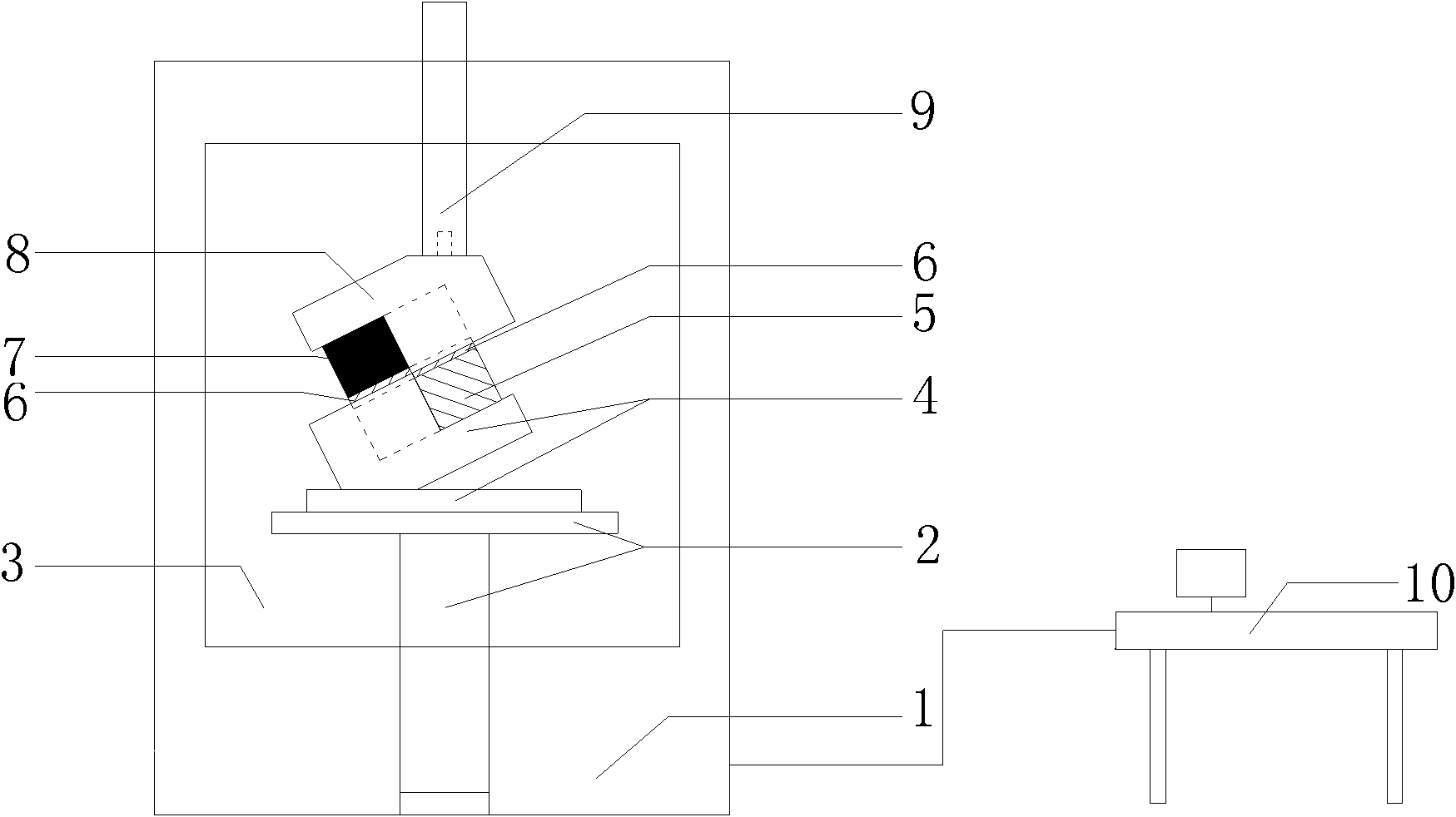

Device for testing composite asphalt pavement interlayer shear fatigue, and method thereof

An asphalt pavement, interlayer shearing technology, applied in the direction of using a stable shear force to test the strength of materials, can solve the problem of inability to accurately evaluate the interlayer shear strength and shear fatigue performance, inconsistent with the stress state of the pavement, etc. problems, to achieve the effect of authenticity and scientificity, convenient operation, and simple structure of the test instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

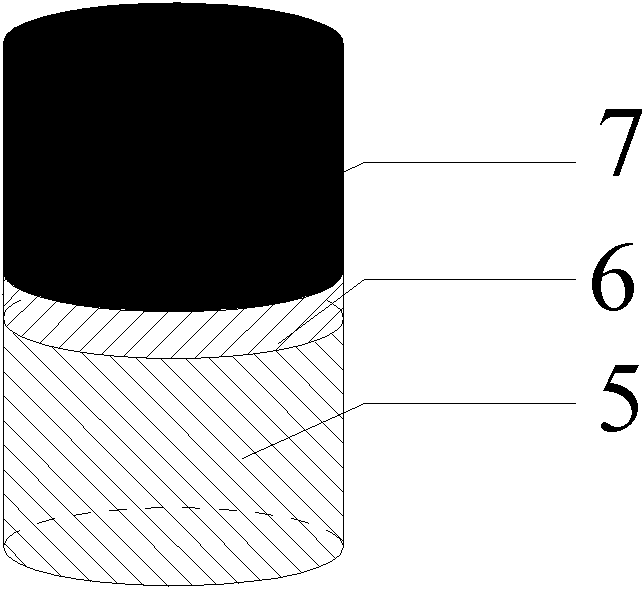

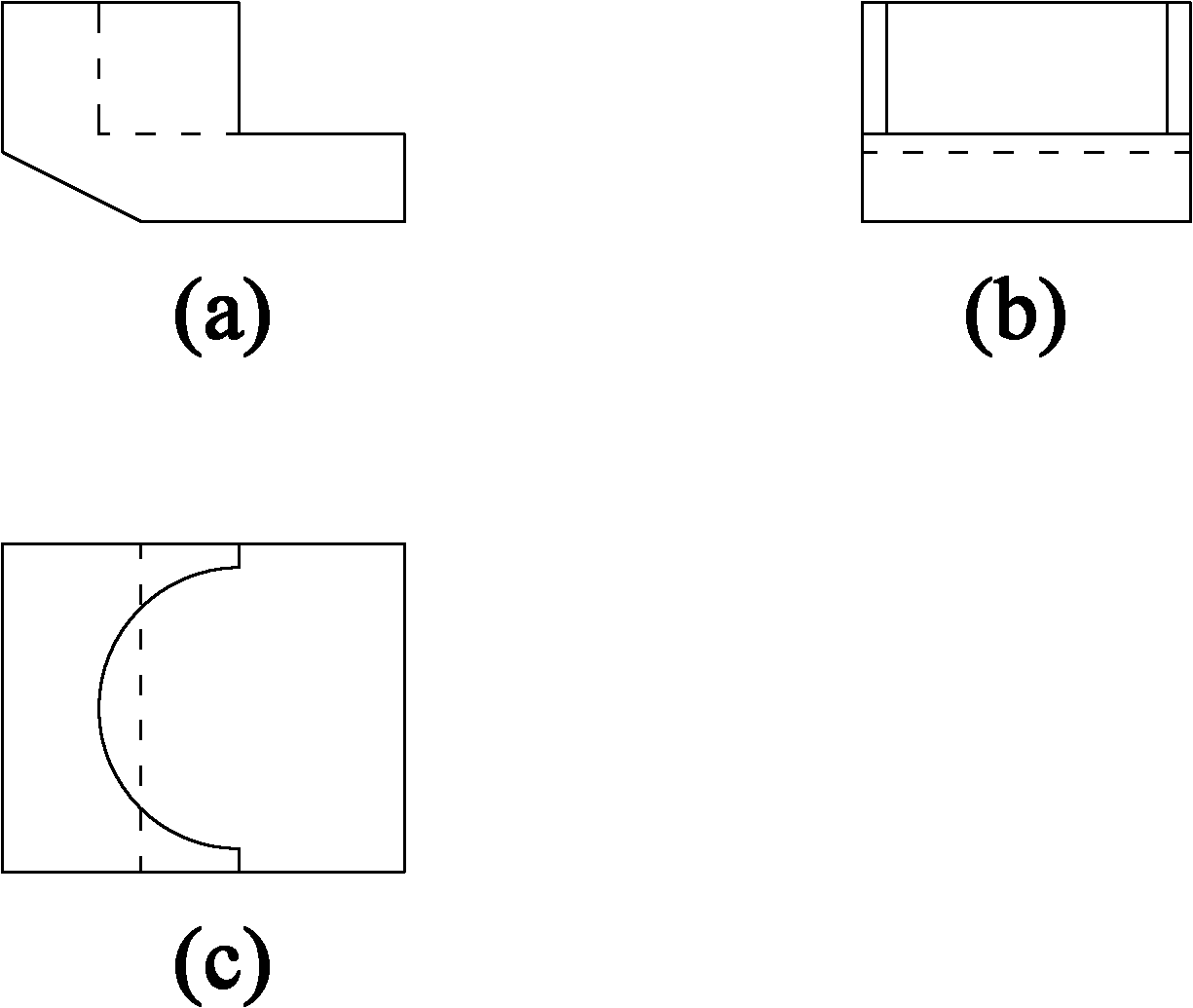

[0042] 1. According to the test requirements, select the pressing block and supporting block with a radius of 50.8mm and a height of 50mm.

[0043] 2. Preparation of Specimen

[0044] 2.1 Fabrication of cement concrete base

[0045] Pour C35 cement concrete specimens in the asphalt mixture Marshall test mold. When pouring cement concrete, it must be vibrated and compacted, and then the surface of the cement concrete base is exposed, and then the specimens are placed in a standard curing room for curing. After curing for 24 hours Lightly tap the mold with a wooden hammer, and then place the specimen in a standard curing room for curing until the strength meets the design requirements.

[0046] 2.2 Fabrication of the bonding layer

[0047] Clean the surface of the test piece whose strength meets the design requirements in step 2.1, and evenly coat the surface with SBS modified asphalt, and then sprinkle gravel with a single particle size of 16mm to 19mm on the surface of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com