Model and method for testing deformation and stress variation law of intensity attenuation roadbed

A test model and stress change technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve problems such as large influence, rationality and representativeness of analysis results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

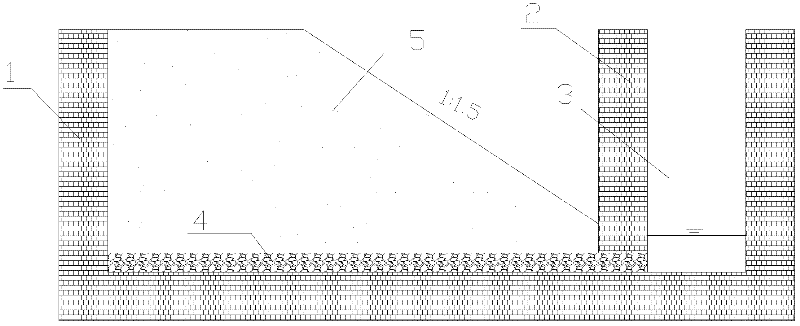

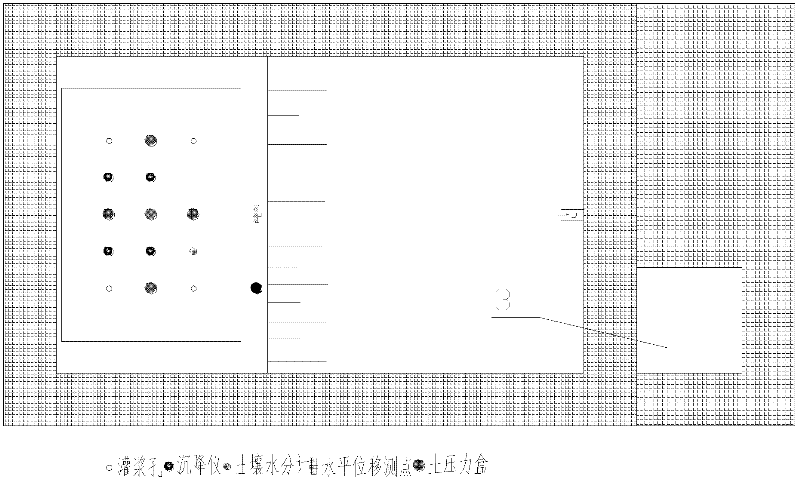

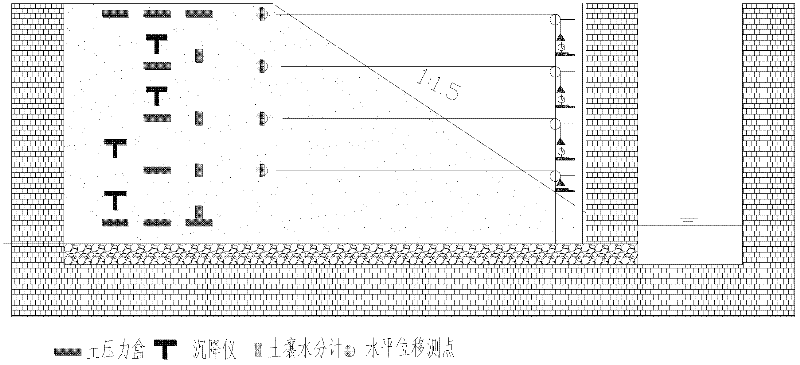

[0065] Such as figure 1 As shown, a strength attenuation roadbed deformation and stress variation test model, including a model body 1, the cavity structure in the model body 1, the cavity structure is divided into two parts by a vertical partition 2, a part is vertical The bottom of the water well 3 is laid with a layer of crushed stone cushion 4, and the crushed stone cushion 4 communicates with the bottom of the vertical water well 3, and the crushed stone cushion 4 is provided with a silt roadbed 5 having the same structure as the half-width roadbed. The slope ratio of the silt subgrade 5 is 1:1.5.

[0066] Model material and size of the present invention

[0067] Similar constants for prototypes and models include:

[0068] Geometric similarity constant: C L =L P / L m Displacement similarity constant: C δ = δ P / δ m

[0069] Stress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com