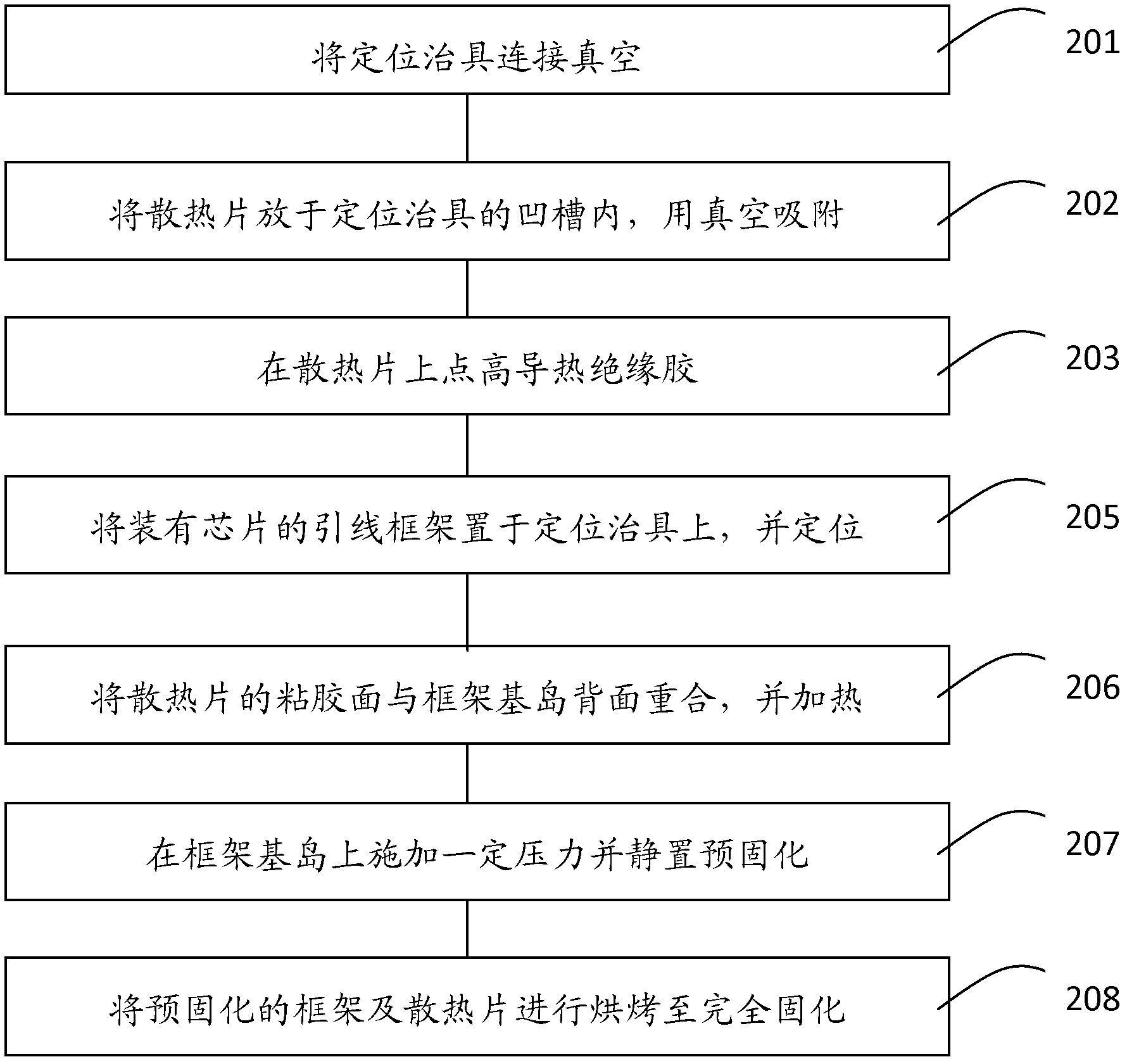

Method for installing cooling fin of high-power module

An installation method and heat sink technology, which are applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as insufficient heat dissipation of power semiconductors, and achieve the effects of simplifying the production process and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

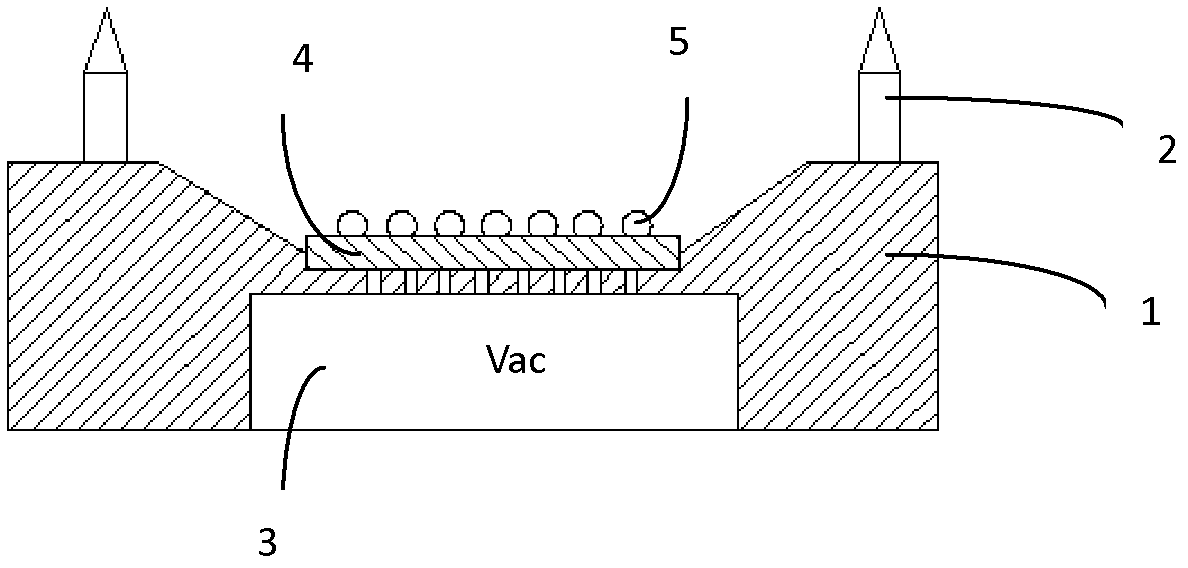

[0036] The structure after the heat sink is installed in this embodiment, such as image 3 As shown, it includes: a lead frame 6 with a chip, a heat sink 4, and a high thermal conductivity insulating glue 5, and one side of the heat sink 4 is bonded to the base island 11 of the lead frame 6 with the chip 9 through the high thermal conductivity insulation glue 5 the other side of Chip 9 is bonded to base island 11 by means of solder 10 .

[0037] The base island is a part of the lead frame 6 equipped with chips, and the base island is stamped and formed by a mold.

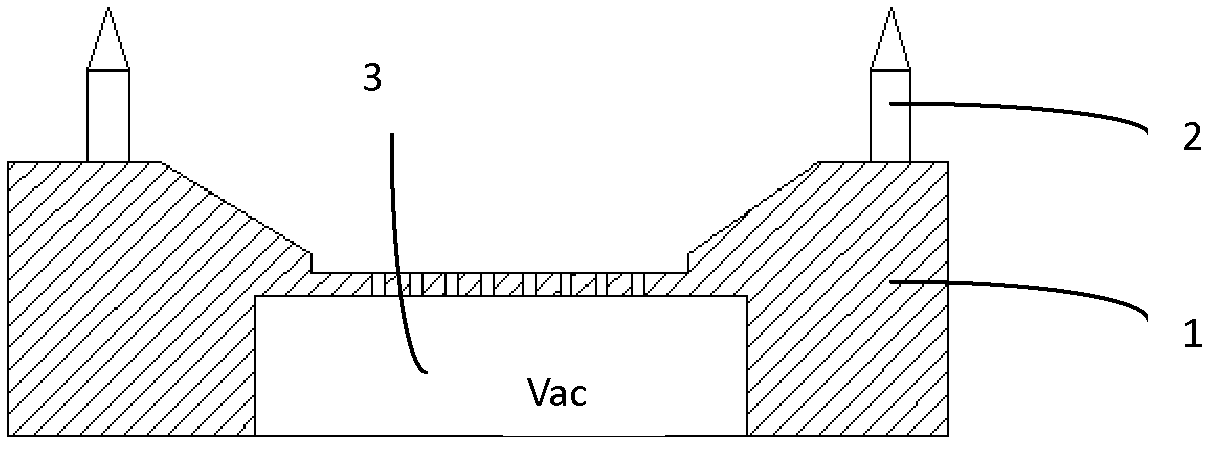

[0038] In the method for installing a heat sink in a module package with a heat sink in this embodiment, first, a lead frame 6 with a chip and a positioning jig 1 need to be prepared. There are positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com