Brushless direct current permanent magnet motor having characteristics of low noise, low vibration and low temperature rise and assembly technology thereof

A permanent magnet motor and assembly process technology, used in the fields of power electronics and machinery, can solve the problems of motor temperature rise, vibration and noise, and can not guarantee the special use requirements of the motor, and achieve the effect of reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

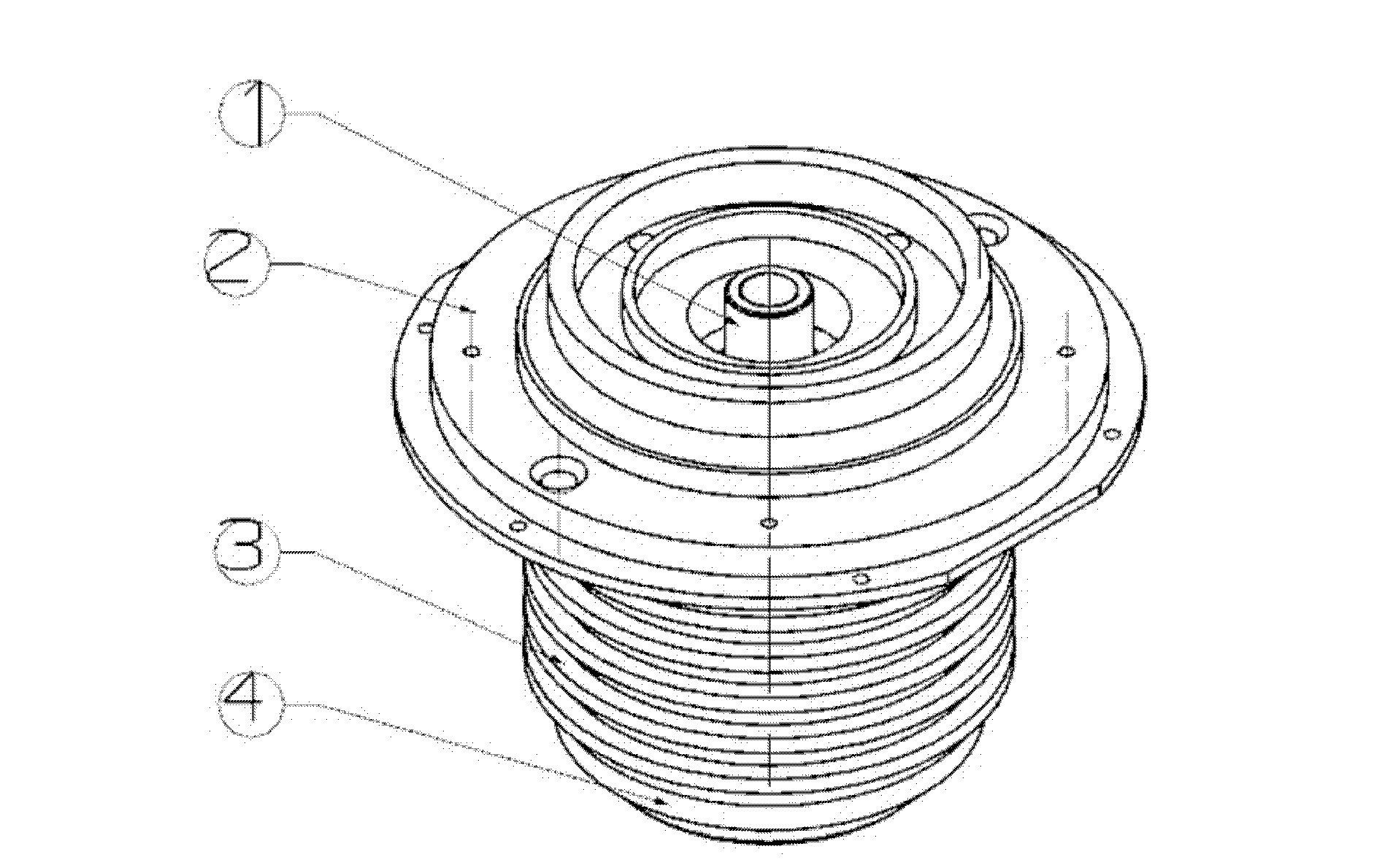

[0021] The shape of the motor is as figure 1 As shown, the improvements made in the structure and assembly are mainly:

[0022] First, heat source control

[0023] The heat source of the motor has two aspects, one is caused by the motor winding, and the other is caused by the friction of the bearing. When the motor is not installed on the frame, the heat loss is about 19.2W. In order to reduce the heat loss of the bearing and at the same time control the stability of the motor's high-speed rotation, a single row deep groove ball bearing with a dust cover is selected to ensure the low loss and stability of the bearing motor under load.

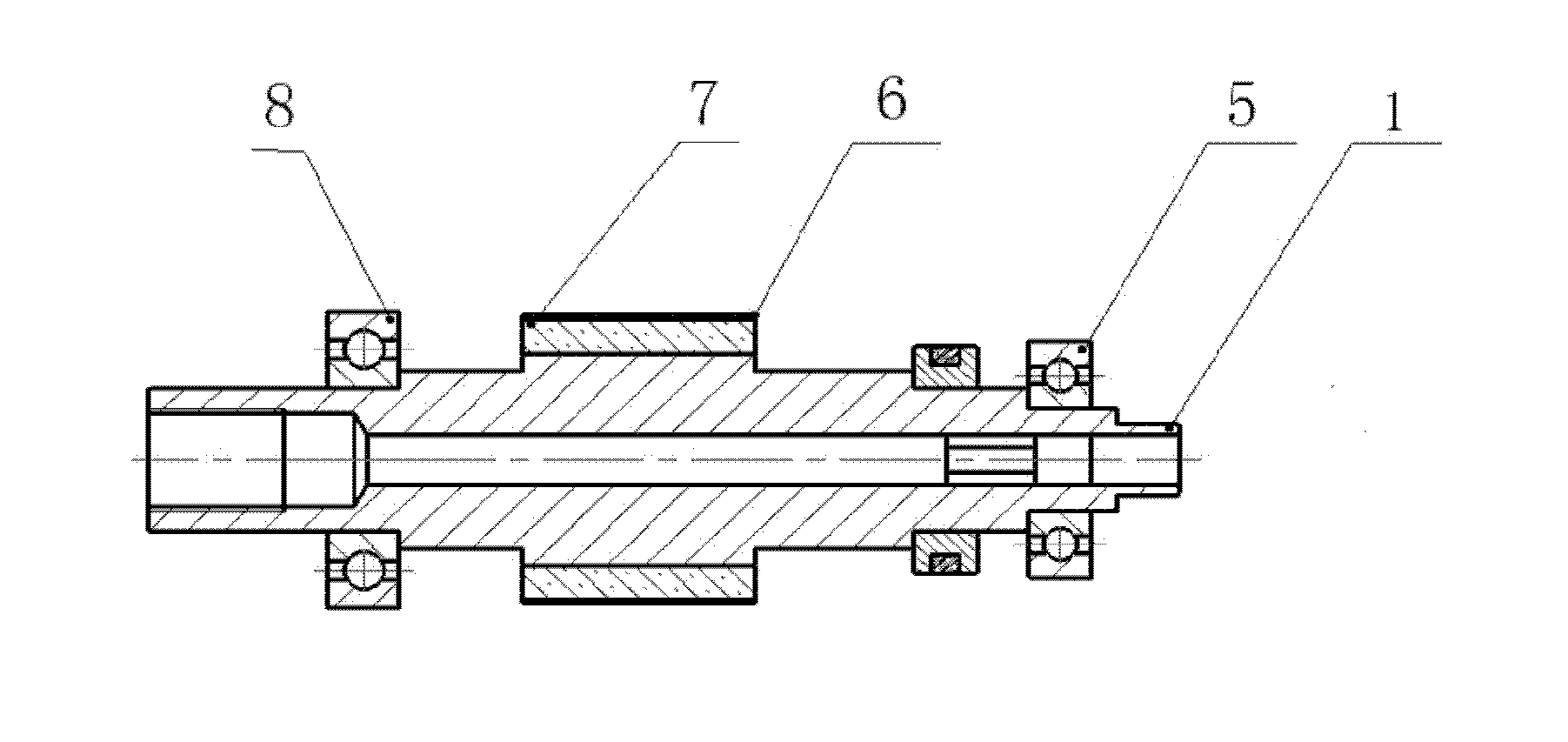

[0024] The installation method of the bearing also has a great influence on the performance of the motor. The specific structure is as follows: figure 2 shown. The motor works at 7000RPM, which is a high-speed rotating motor. The bearing installation is mainly based on interference installation, but the interference has a great influence o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com