Local heating method and device for multi-span greenhouse

A local heating and greenhouse technology, applied in the direction of climate change adaptation, application, cultivation, etc., can solve problems such as difficult installation and daily maintenance, inability to realize continuous power supply, and low utilization rate of photoelectric conversion, so as to improve reasonable utilization rate and install Simple, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings:

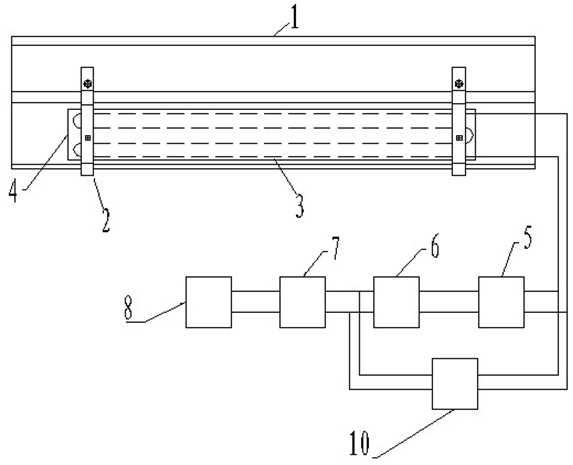

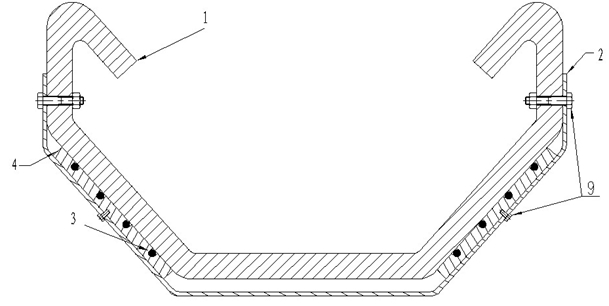

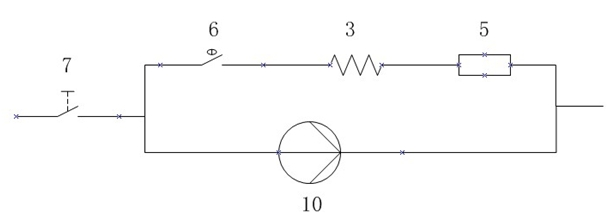

[0020] As attached figure 1 A local heating system for a multi-span greenhouse is shown. The heating wire 3, the leakage protector 5, the intelligent temperature control switch 6, and the main power switch 7 are connected in sequence and connected to the external power supply 8. The heating wire 3 is installed in the multi-span greenhouse. On the left and right sides of the groove 1, the heating wires 3 are fixed in the U-shaped arc-shaped groove of the guard plate 4, and the front and rear ends of the guard plate 4 are installed with fastening fixtures 2 to be fixed on the gutter 1.

[0021] The heating wire 3 is one of various alloy heating wires such as iron-chromium-aluminum alloy heating wires or nickel-chromium alloy heating wires with insulation treatment. The heating wires can be replaced with suitable heating bricks or silicon according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com