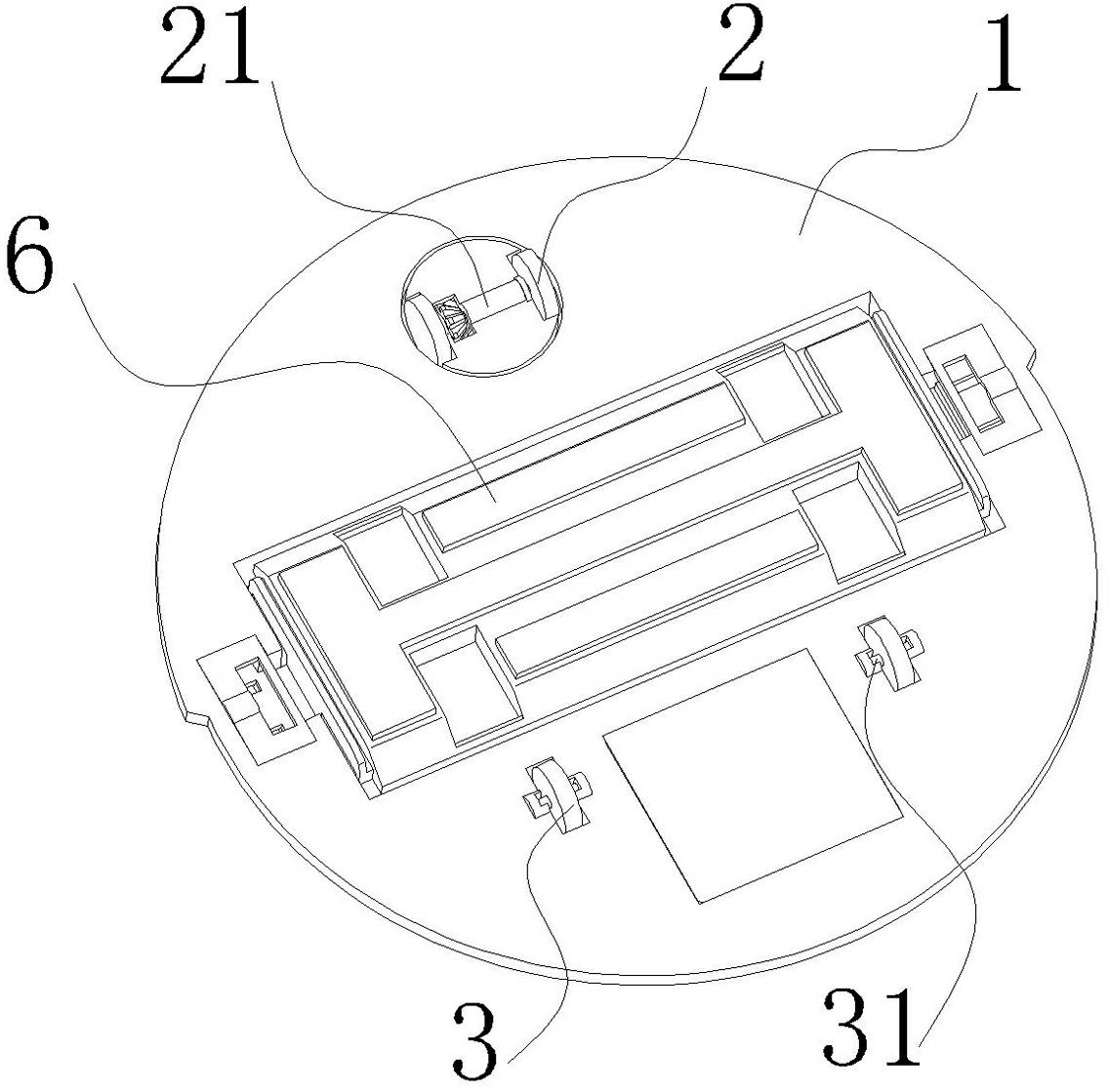

Self-regulating compaction rag of automatic floor mopping machine

An automatic wiping and self-adjusting technology, which is applied in the direction of cleaning carpets, floors, machine parts, etc., can solve the problems that the wiping effect cannot be guaranteed, the motor is easy to burn, and the service life of the mopping machine is reduced, so as to achieve good mopping effect, Ingenious design, easy to disassemble and adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

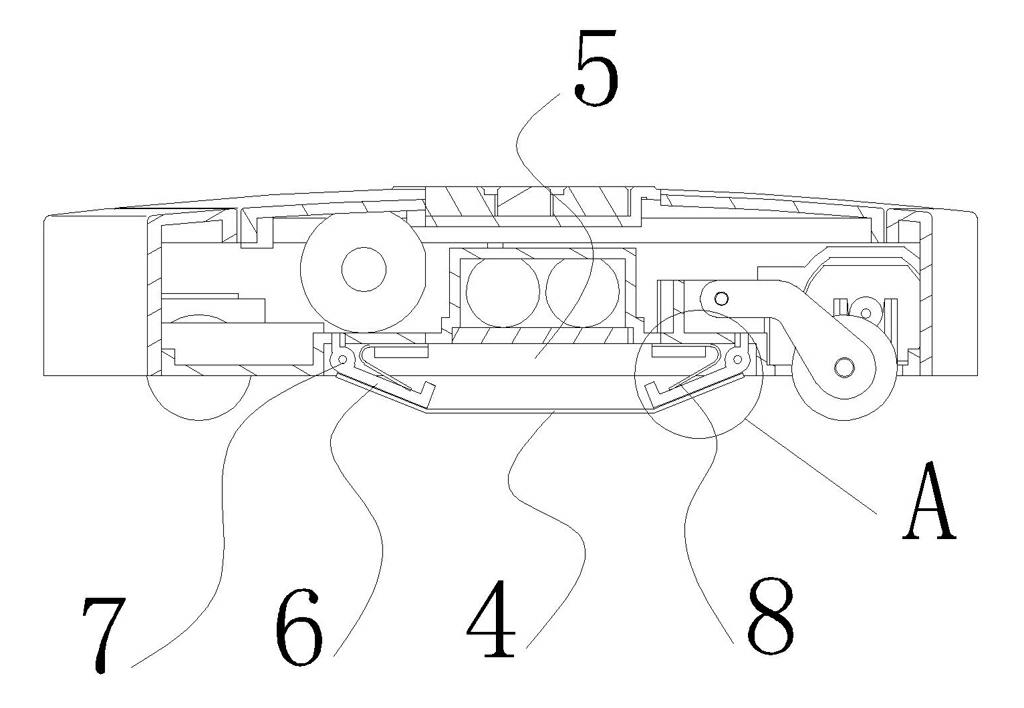

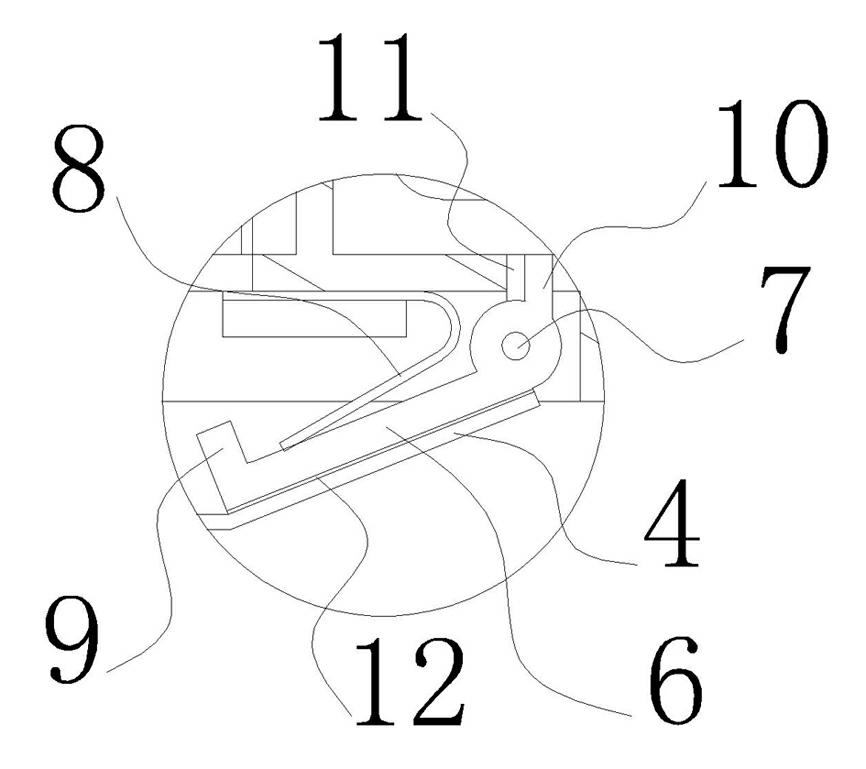

[0018] During use, there is a pre-tightening stroke in the rag 4 after the installation is completed, and finally the maximum angle of rotation of the rotating plate 6 is limited by the block 11 to ensure that the front wheel 2 and the rear wheel 3 are in full contact with the ground when the rag 4 is fully contacted. There is a certain frictional force with the ground. When the work starts, the front end of the rag 4 bears the largest force. When the resistance it receives exceeds the elastic force of the "V"-shaped elastic splint 8, the "V"-shaped elastic splint 8 deforms, and the rotating plate 6 moves upward. Turn the rag 4 upwards, the rag 4 changes from tight to loose, and the friction between the rag 4 and the ground decreases accordingly, and the motor can provide enough power without overloading until the mopping machine crosses the resistance road surface, and the rotating plate 6 is in the position of "V". The "shaped elastic splint 8 restores to the original state u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com