Pressure-reducing type asphalt four-component separating device

The technology of a separation device and a decompression device is applied in separation methods, liquid separation of solid adsorbents, preparation of samples for testing, etc., and can solve the problems of difficult to control the air pressure of the adsorption column, inaccurate experimental data, and different liquid flow rates, etc. To achieve the effect of reducing experimental human error, ensuring personal safety, and stable experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0017] Implementation case 1: The specific operation of separating a group of samples.

[0018] 1. Preparation

[0019] Prepare according to the provisions of T0618-1993 asphalt chemical component test (four-component method) in JTJ052-2000 highway engineering asphalt and asphalt mixture test regulations: activate 50g of aluminum oxide at 500°C for 6h; Heptane 100mL; Weigh about 1.0g of Esso 90# road petroleum asphalt test sample, after boiling, filtering and concentrating to obtain 10mL filtrate; 3 weighed 150mL round bottom flasks (asphaltene is not included in the treated 10mL of filtrate).

[0020] 2. Experimental procedure

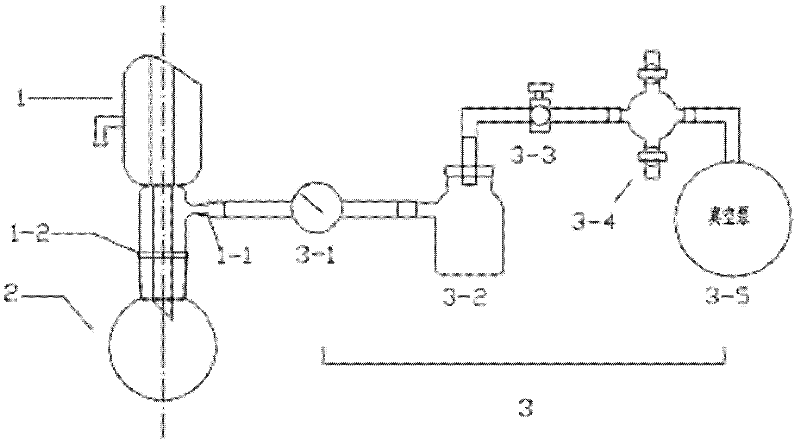

[0021] (1), according to figure 1 Assemble the decompression-type asphalt four-component separation device in the sequence shown, and feed circulating water at 50±1°C;

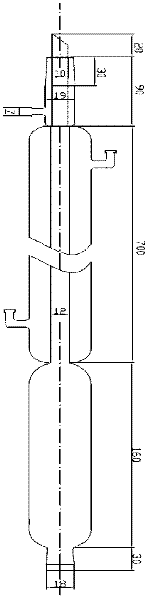

[0022] (2), add 50g of Al2O3 prepared from the feed port at the upper end of the glass adsorption column, oscillate to ensure that Al2O3 in the stationary phase is tight, add 30mL...

Embodiment example 2

[0035] Implementation case 2: The specific operation of separating three groups of samples at the same time.

[0036] 1. Preparation

[0037] According to the description in Example 1, prepare three groups of the same test articles and number them respectively as Groups I, II and III.

[0038] 2. Experimental procedure

[0039] (1), according to figure 1 Assemble the decompression-type asphalt four-component separation device in the sequence shown, and connect two sets of the same device (excluding the vacuum pump) in parallel at the two valve ports of the four-port diverter valve. The rubber tubes are connected in series in sequence, and the circulating water at 50°C±1°C is passed through;

[0040] (2), groups I, II, and III were operated independently, and the specific steps were the same as steps (2), (3), (4), (5), and (6) in the implementation case 1-2.

[0041] 3. Analysis of Experimental Data

[0042] (1) Use a rotary evaporator to remove the eluents in No. 1, No. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com