Dust catcher

A dust collector, the same technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agent, etc., can solve the problems of poor gas passage, blockage of solid particles, complex structure, etc., and achieve simple structure, material saving, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

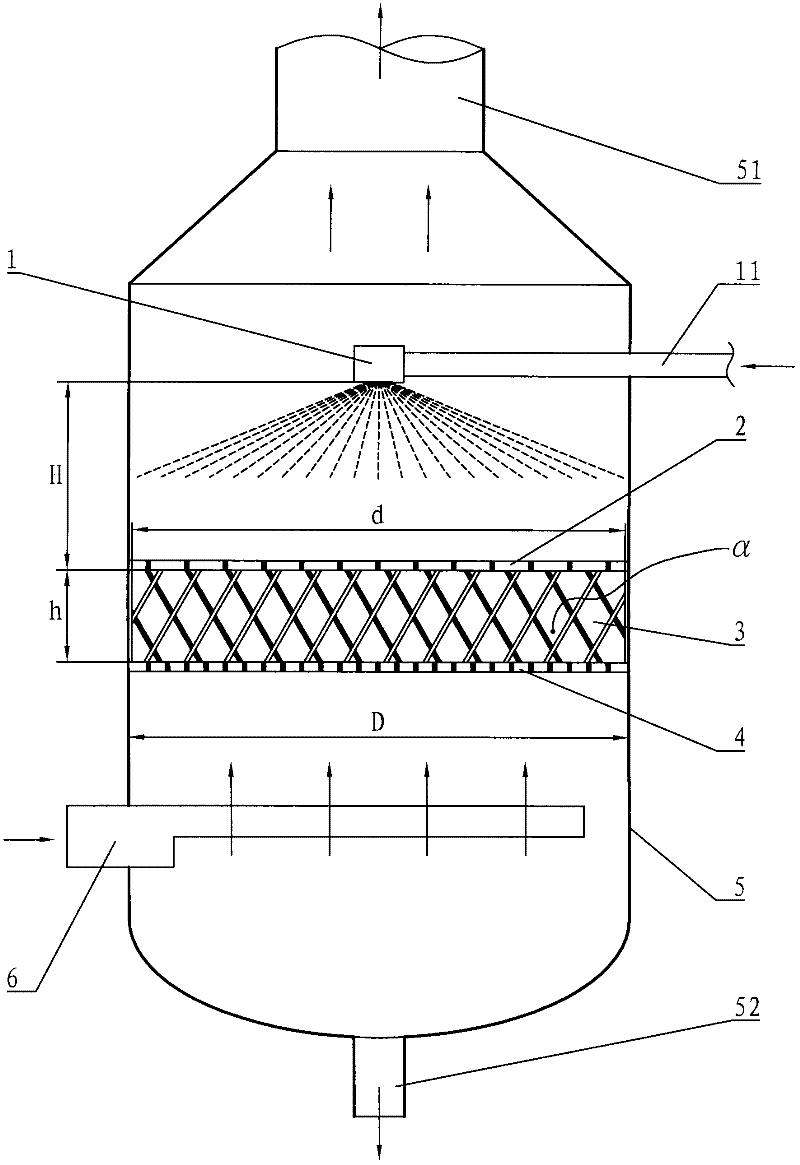

[0031] use figure 1 The shown stand-alone dust collector of the present invention was tested at normal temperature and pressure. Gas containing solid particles was simulated by air containing catalyst particles, the content of catalyst particles was 800 mg / m3. The catalyst is a petroleum processing fluidized catalytic cracking catalyst (spent catalyst), and the bulk density (compressed state) is 1 g / cubic centimeter. The proportion of particles with an equivalent diameter of less than 50 microns is 89.87w% (w% means weight percentage), and the proportion of particles with an equivalent diameter of more than 50 microns is 10.13w%. During operation, the superficial gas velocity is 6.56 m / s, and the liquid-gas ratio is 0.1 liter / cubic meter. The flow rate of the air containing catalyst particles entering the casing 5 from the gas distributor 6 is 26700 cubic meters per hour.

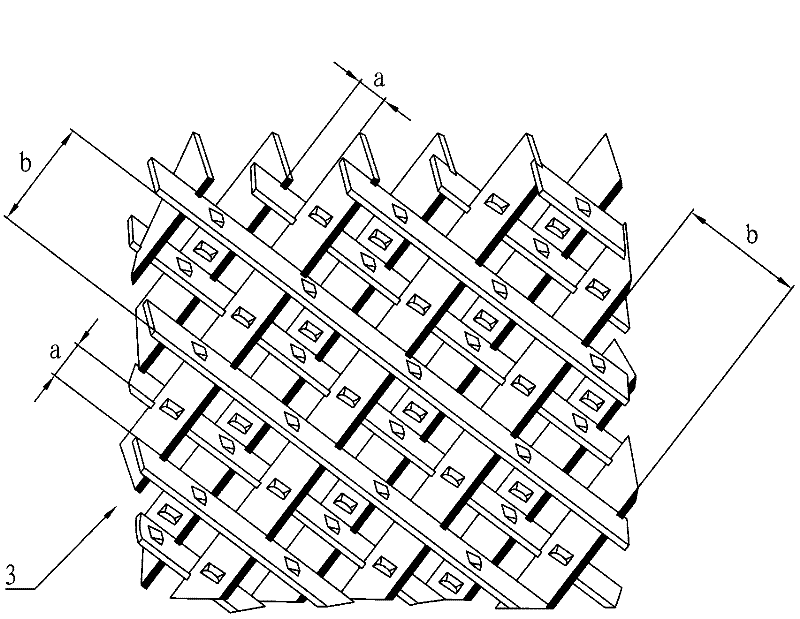

[0032] The grid filler 3 is disc-shaped, with a diameter d of 1.2 meters and a height h of 400 mm. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com