Numerical-control heating bending die and forming method for large-diameter thin-wall pure titanium tube

A technology for heating, bending and forming molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., to achieve the effect of ensuring strength, reducing energy consumption, and improving lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

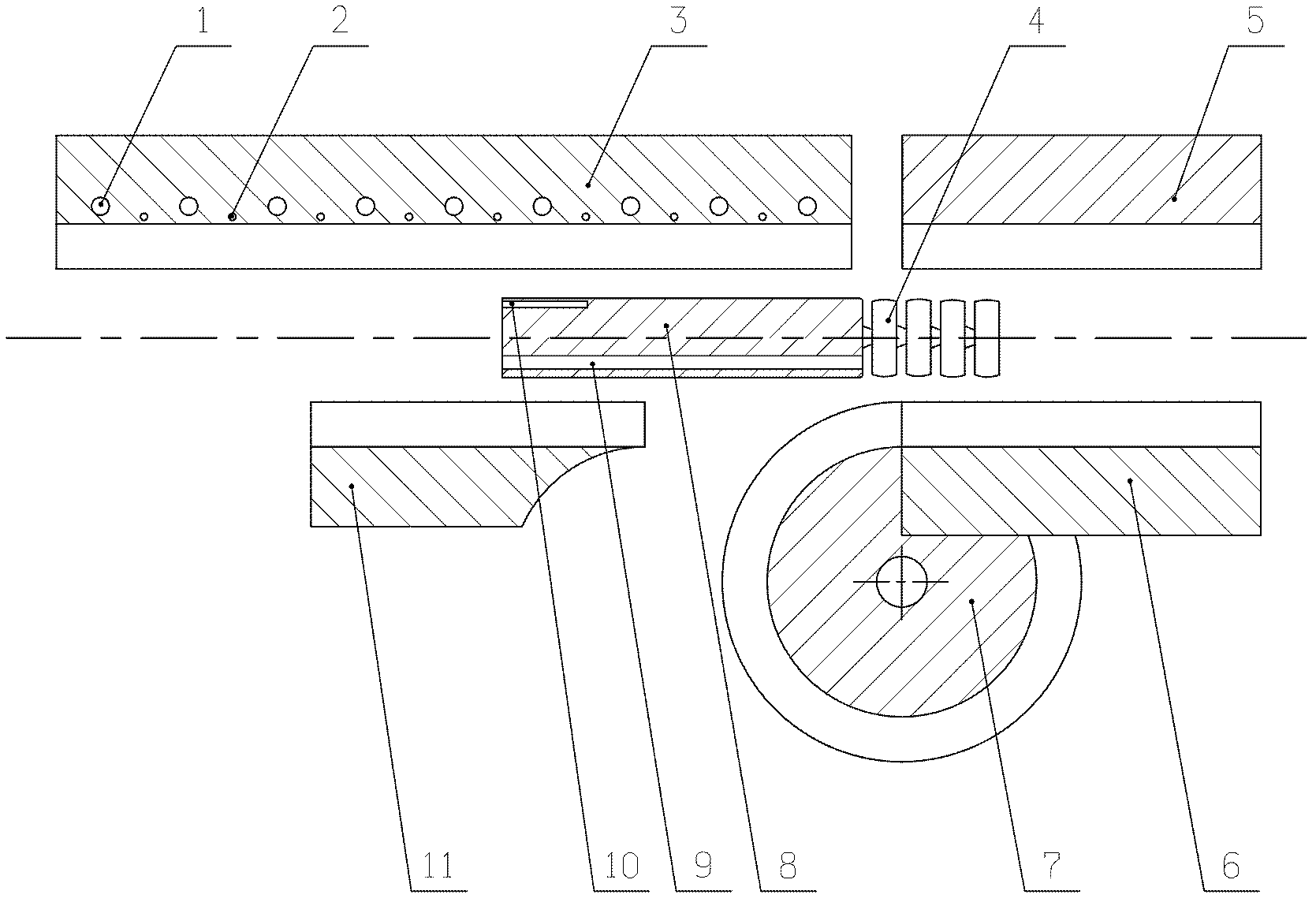

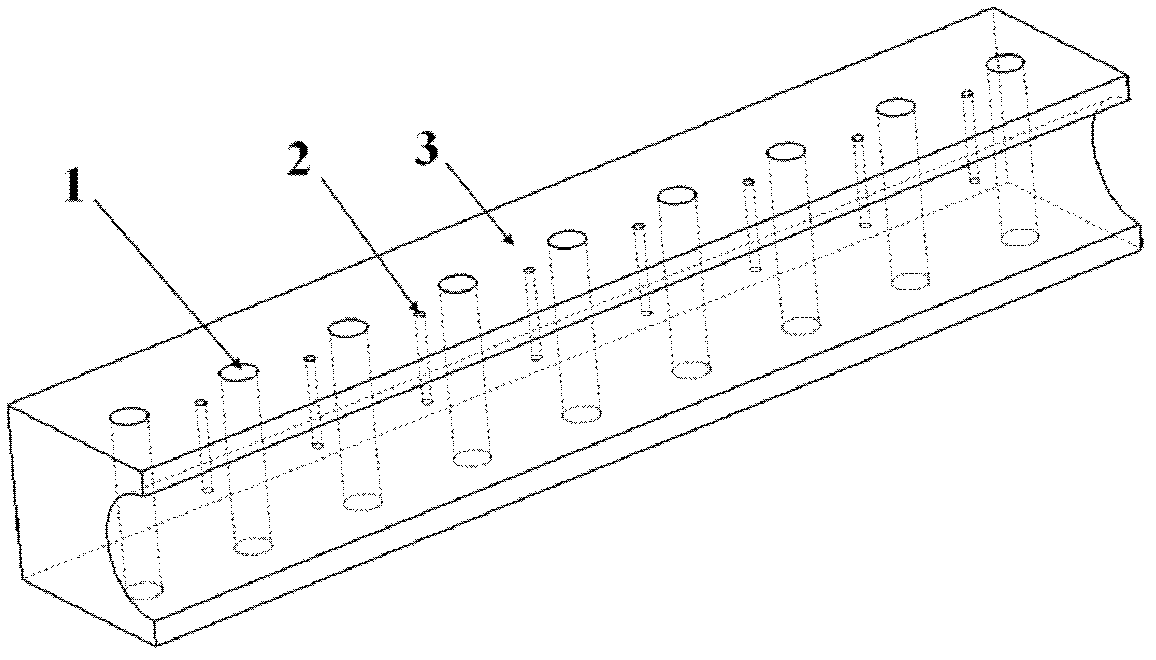

[0039] This embodiment is a thin-walled pure titanium tube numerical control heating bending forming mold.

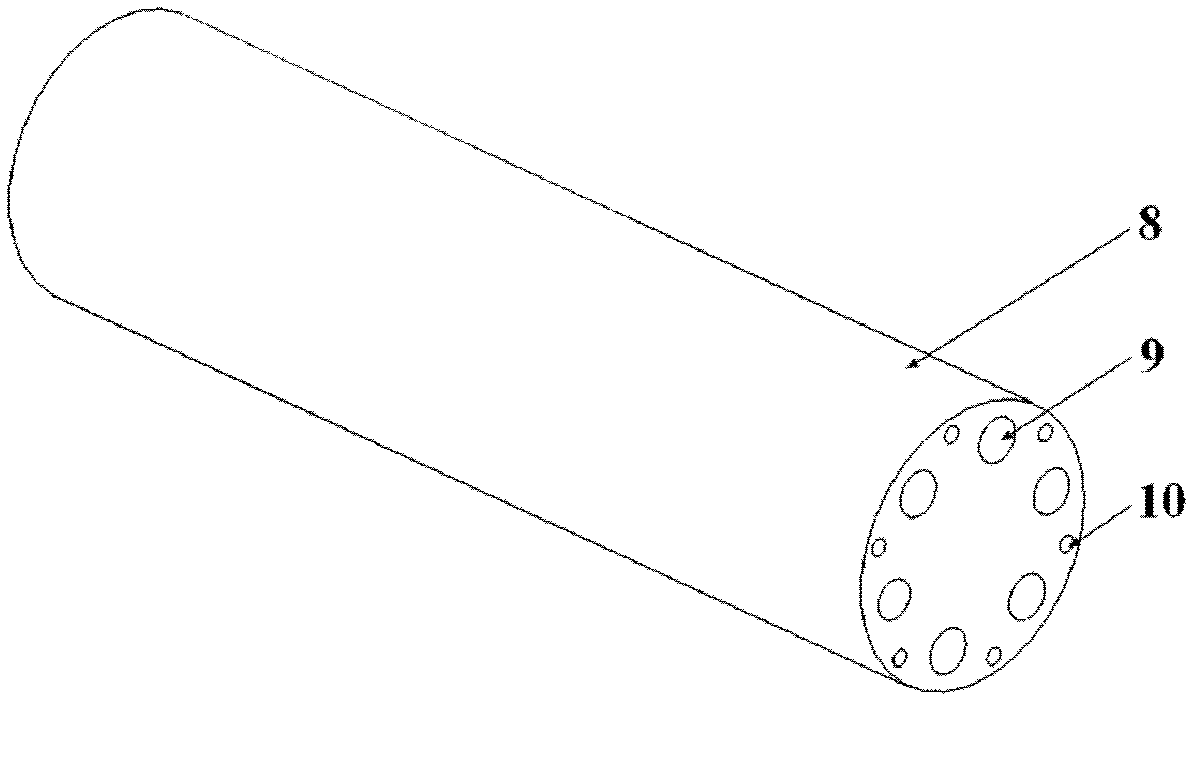

[0040] The mold described in this embodiment is obtained by improving the prior art CNC room temperature bending forming mold and the CNC pipe bending machine mold for hot bending, including the pressure mold 3, the clamping mold 5, the insert 6, and the bending mold. 7. Anti-wrinkle mold 11 and core mold. The core mold includes a core rod 8 and a core ball 4. In this embodiment, a heating hole and a temperature measuring hole are added to the pressure die 3 and the core rod 8 respectively, and the diameter of the core rod 8 is optimized to meet the requirements for numerically controlled heating and bending of a thin-walled pure titanium tube with a small bending radius and a large diameter. The specific technical solution of this embodiment is:

[0041] One side surface of the pressure die 3 is a concave arc-shaped pressure die forming surface for matching with the outer...

Embodiment 2

[0061] This embodiment is a method for forming a thin-walled pure titanium tube by numerically controlled heating using the mold described in the first embodiment.

[0062] In this embodiment, the standard is SAEAMS4941E, and the 2008 specification is Φ50.8×t0.508, that is, a pure titanium tube with a diameter D of 50.8 mm and a wall thickness t of 0.508 mm. The pure titanium tube has a D / t= 100, the bending radius R=2D.

[0063] The specific implementation process includes the following steps:

[0064] In the first step, the mold and the pipe bender are insulated. Place the pressure mold heat insulation board 13 between the assembly surface of the pressure mold 3 and the machine tool connection surface, and place the crease mold heat insulation board 12 between the anti-wrinkle mold 11 and the machine tool connection surface. The wrinkle mold heat insulation board 12 realizes heat insulation between the mold and the pipe bender. The pressure mold heat insulation board 13 and the ...

Embodiment 3

[0079] The standard used in this embodiment is SAE AMS4941E, the 2008 specification is Φ76.2×t1.0668, that is, a pure titanium tube with a diameter D of 76.2mm and a wall thickness t of 1.0668mm. The D / t = 71.4, bending radius R = 2D.

[0080] The specific implementation process includes the following steps:

[0081] In the first step, the mold and the pipe bender are insulated. Place the pressure mold heat insulation board 13 between the assembly surface of the pressure mold 3 and the machine tool connection surface, and place the crease mold heat insulation board 12 between the anti-wrinkle mold 11 and the machine tool connection surface. The wrinkle mold heat insulation board 12 realizes heat insulation between the mold and the pipe bender. The pressure mold heat insulation board 13 and the anti-wrinkle mold heat insulation board 12 are made of fiber composite material heat insulation boards for stamping.

[0082] The second step is to assemble and debug the mold. The mold is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com