System and method for forming disk part by performing two-stage atomizing and spraying

A spray forming and atomizing nozzle technology, which is applied in the field of atomization of molten metal and deposition of metal droplets, can solve the problems of large-diameter axisymmetric central hole parts with large difficulty, low gas density, and low momentum, etc., to achieve Reduce the densification process, reduce the average particle size, and improve the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

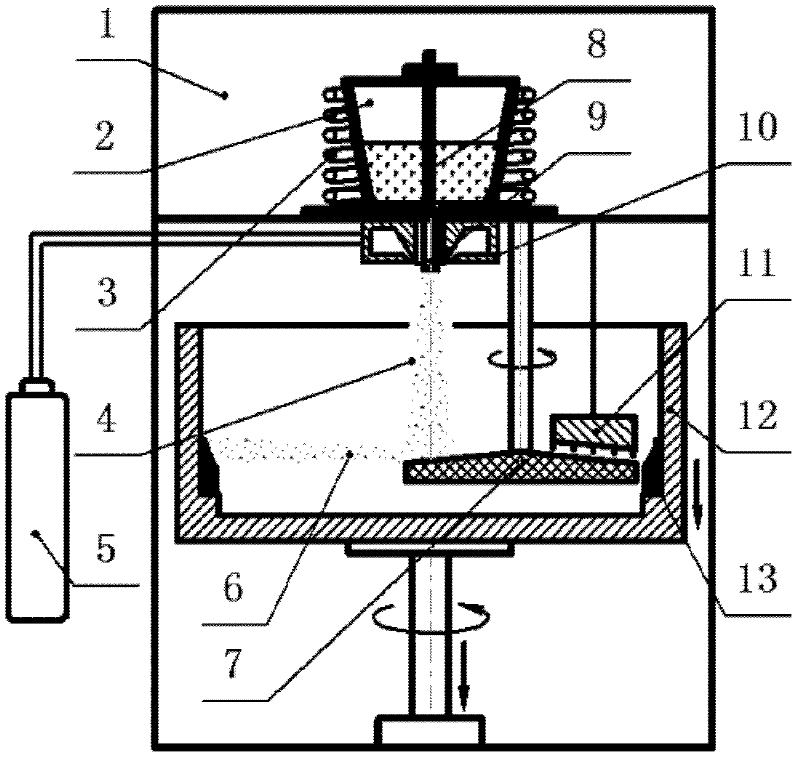

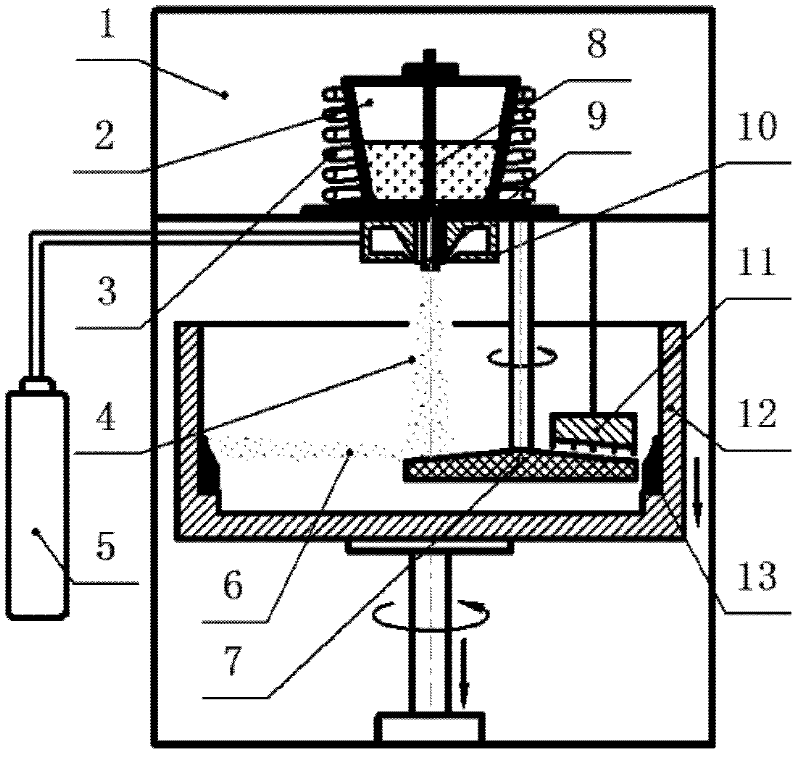

[0020] The system of this embodiment comprises a vacuum chamber 1 with an internal size of 2 m high and a diameter of 1.2 m, a crucible 2 with a height of 0.2 m and a diameter of 0.18 m, a heating coil 3, a gas storage cylinder 5, a mechanical ejection disc 7 with a diameter of 0.3 m, and Through rod 8, catheter tube 9, high-pressure gas atomization nozzle 10, cooling device 11 and ring mold 12 with a diameter of 0.8m; wherein crucible 2, heating coil 3, stop rod 8, catheter tube 9 and atomization nozzle 10 Located in the upper part of the vacuum chamber 1, the crucible 2 is located in the center of the upper part of the vacuum tank 1, and is connected to the catheter 9 through the threaded hole at the bottom, and the stop rod 8 is connected to the catheter 9 and the bottom of the crucible 2 The threaded through holes are coaxial, and can move up and down along i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com