Device for machining ultra-large lead inner helixes of machine barrel of plastic extruder

A processing device and internal screw technology, which is applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., to achieve the effects of convenient manufacturing, simple structure and good adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

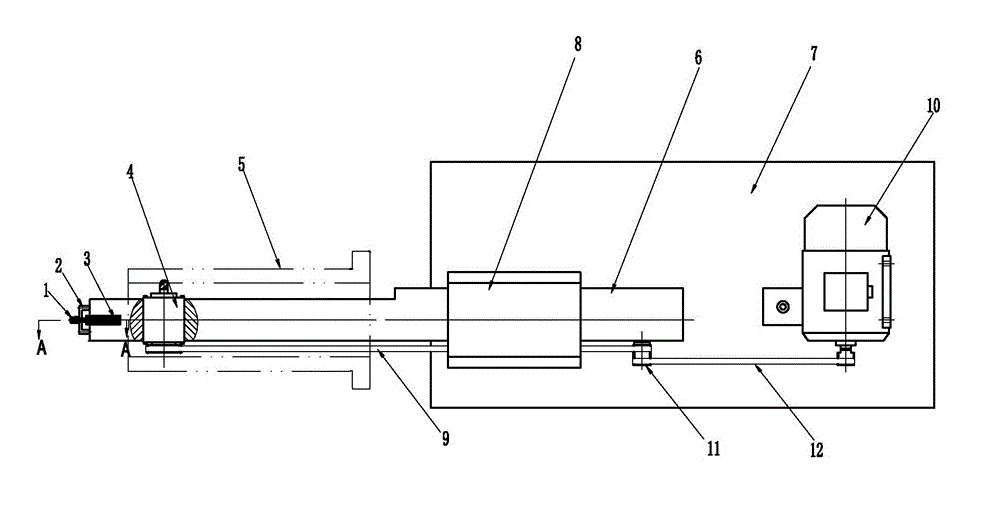

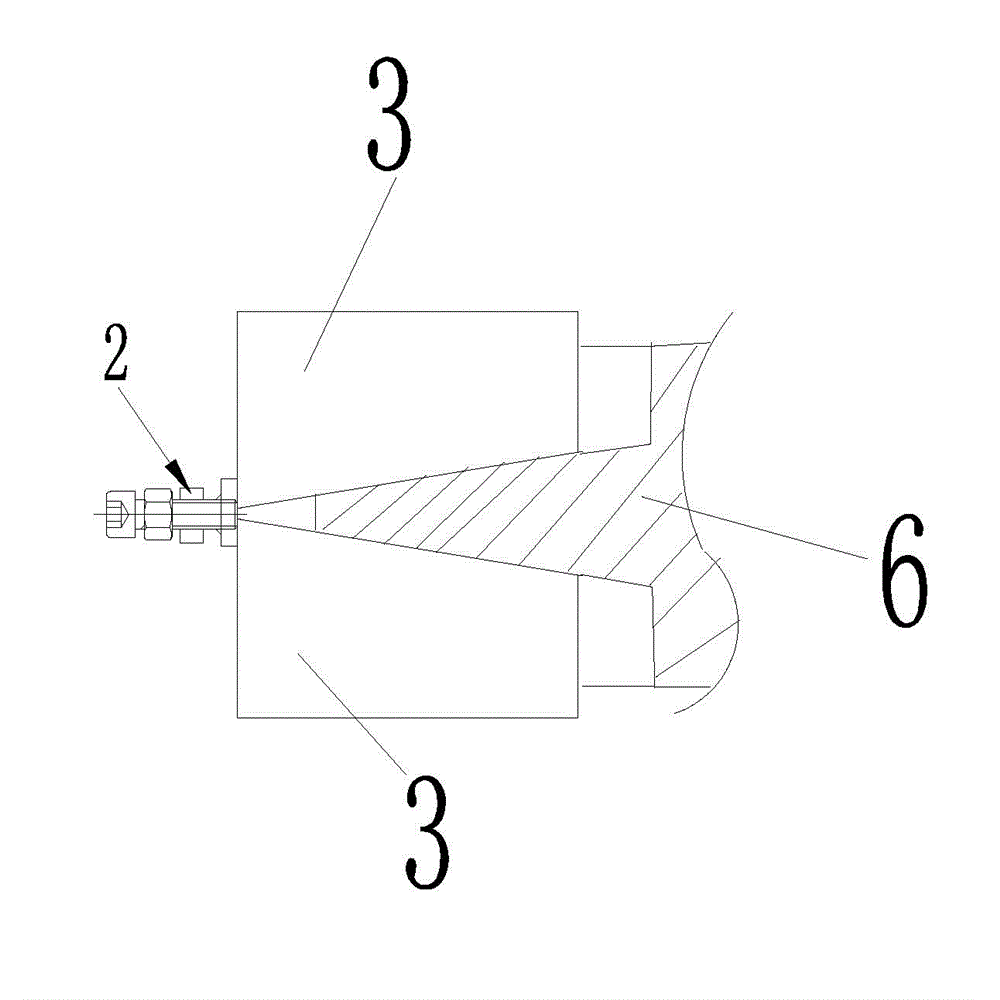

[0019] Such as figure 1 shown.

[0020] A plastic extruder barrel super-lead internal helix processing device for use with a data screw milling machine, which includes a base plate 7, a support seat 8 and a power device 10, and the support seat 8 and the power device 10 can be installed on the On the base plate 7, the power unit 10 can also be installed on the bed of the CNC screw milling machine or other positions to provide power for the micro-milling head. During specific implementation, the power unit 10 can adopt a mechanical stepless transmission driven by a motor. Step speed changer is also installed on the base plate 7, and output pulley is installed on its output shaft. When in use, the base plate 7 can be fixed on the CNC milling machine by a conventional clamping device. After use, the base plate 7 can be removed from the data milling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com