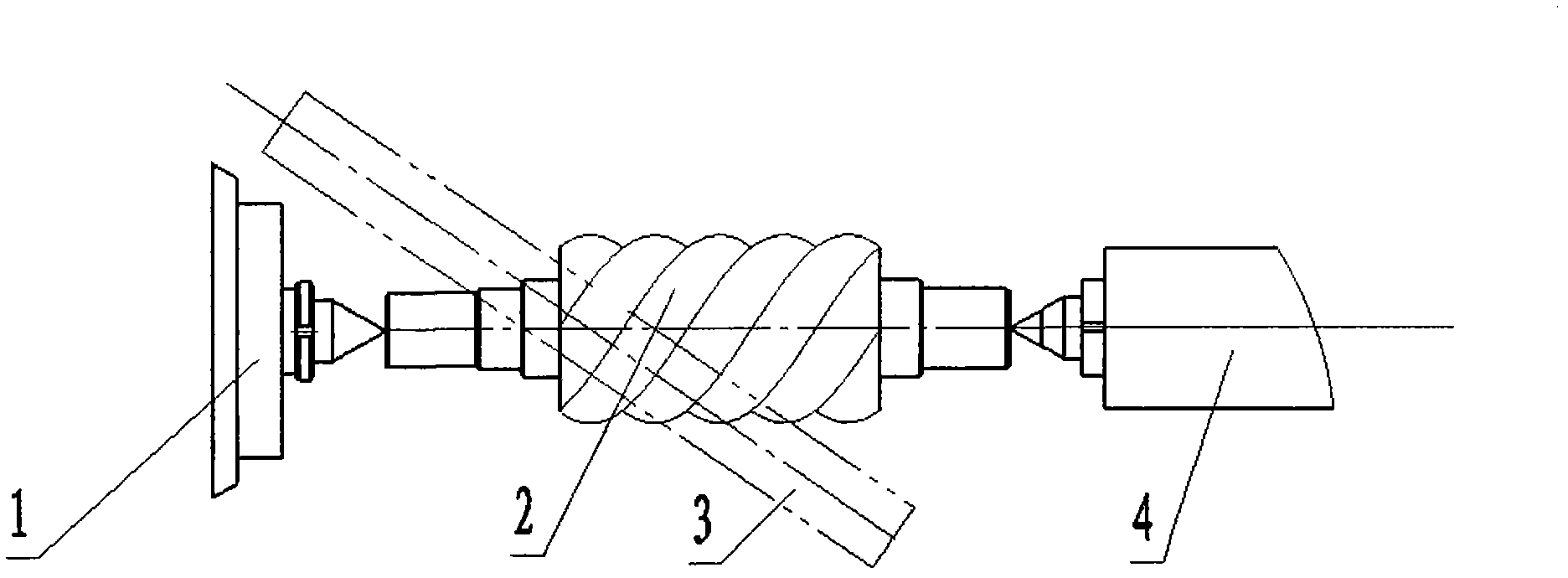

High-precision numerically-controlled rotor grinding machine

A high-precision, rotor technology that can be used in gear teeth, components with teeth, belts/chains/gears, etc., to solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

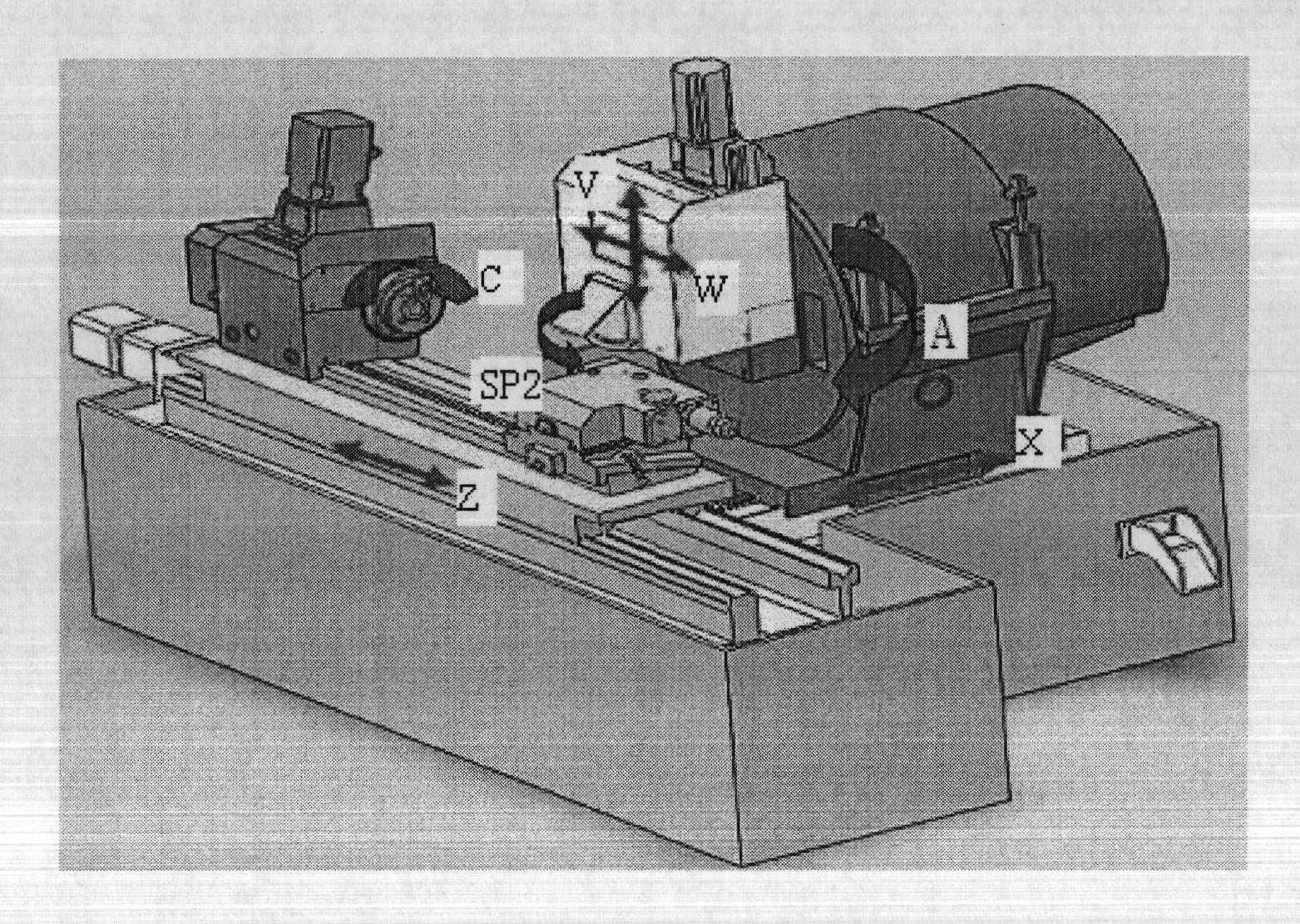

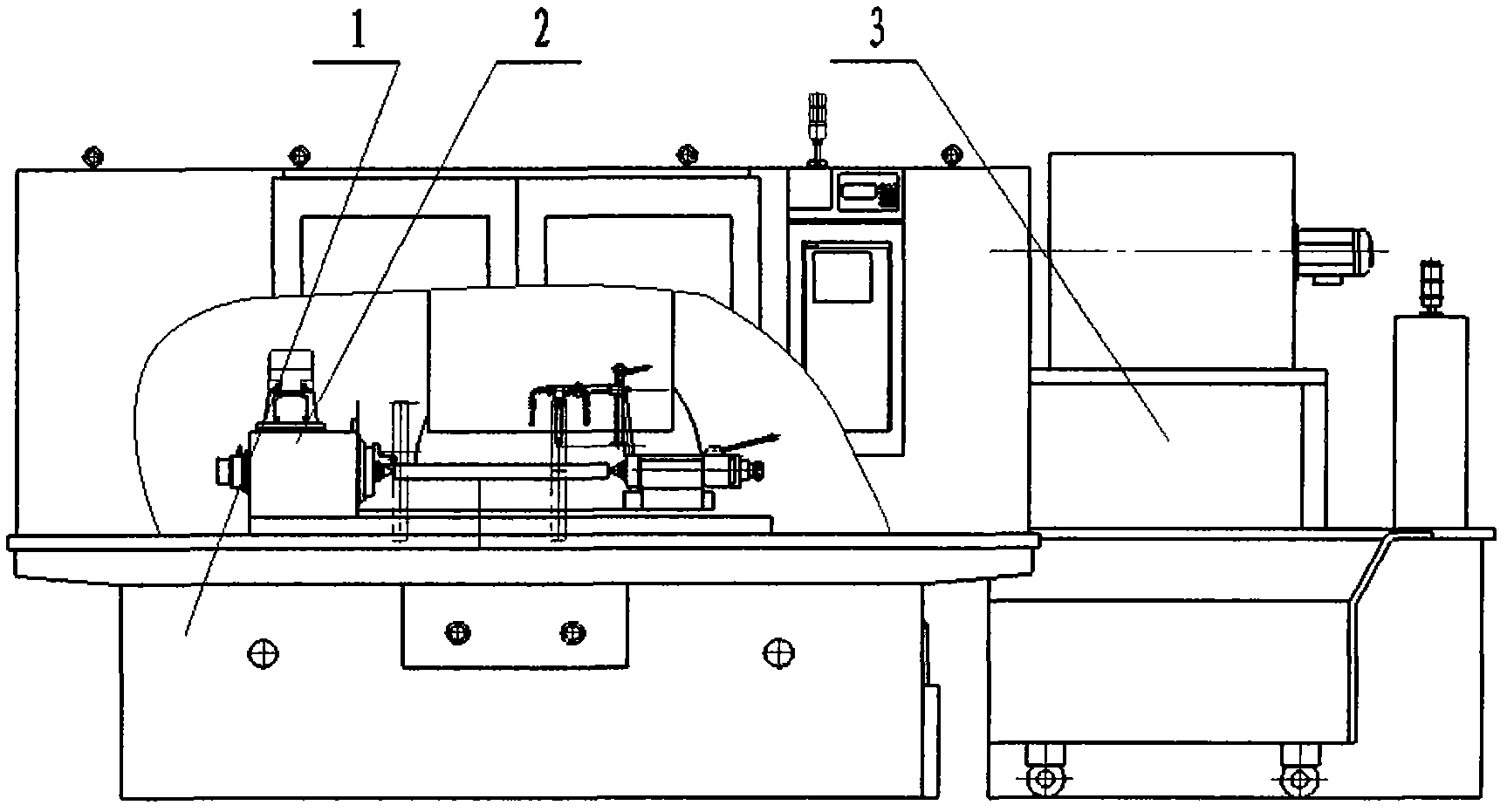

[0020] Below in conjunction with accompanying drawing and specific embodiment this scheme is described further:

[0021] The high-precision CNC rotor grinding machine described in this plan is mainly composed of a bed 1, a worktable 10, a headstock 2, a tailstock 11, a grinding wheel frame 5, a precision abrasive tool, and a grinding wheel dressing device 6. The bed 1 is the basic part of the machine tool, used to support other main components of the machine tool, and is equipped with a linear transmission device for the longitudinal movement of the workbench 10 . The headstock 2 and tailstock 11 are installed on the workbench 10, and the workpiece is supported by a special fixture between the headstock 2 and the tailstock 11, and the rotation of the headstock 2 drives the workpiece to rotate to complete the rotation required for the rotor grinding process. sports. The grinding wheel frame 5 is located at the rear of the machine tool bed 1, and the grinding wheel and the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com