Minimal quantity lubrication (MQL) supply system for processing of outer-cooling type high-speed machine tool and inner-cooling type high-speed machine tool

A technology of minimal quantity lubrication and supply system, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., to achieve the effects of no waste liquid discharge, cost reduction, and good lubrication and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

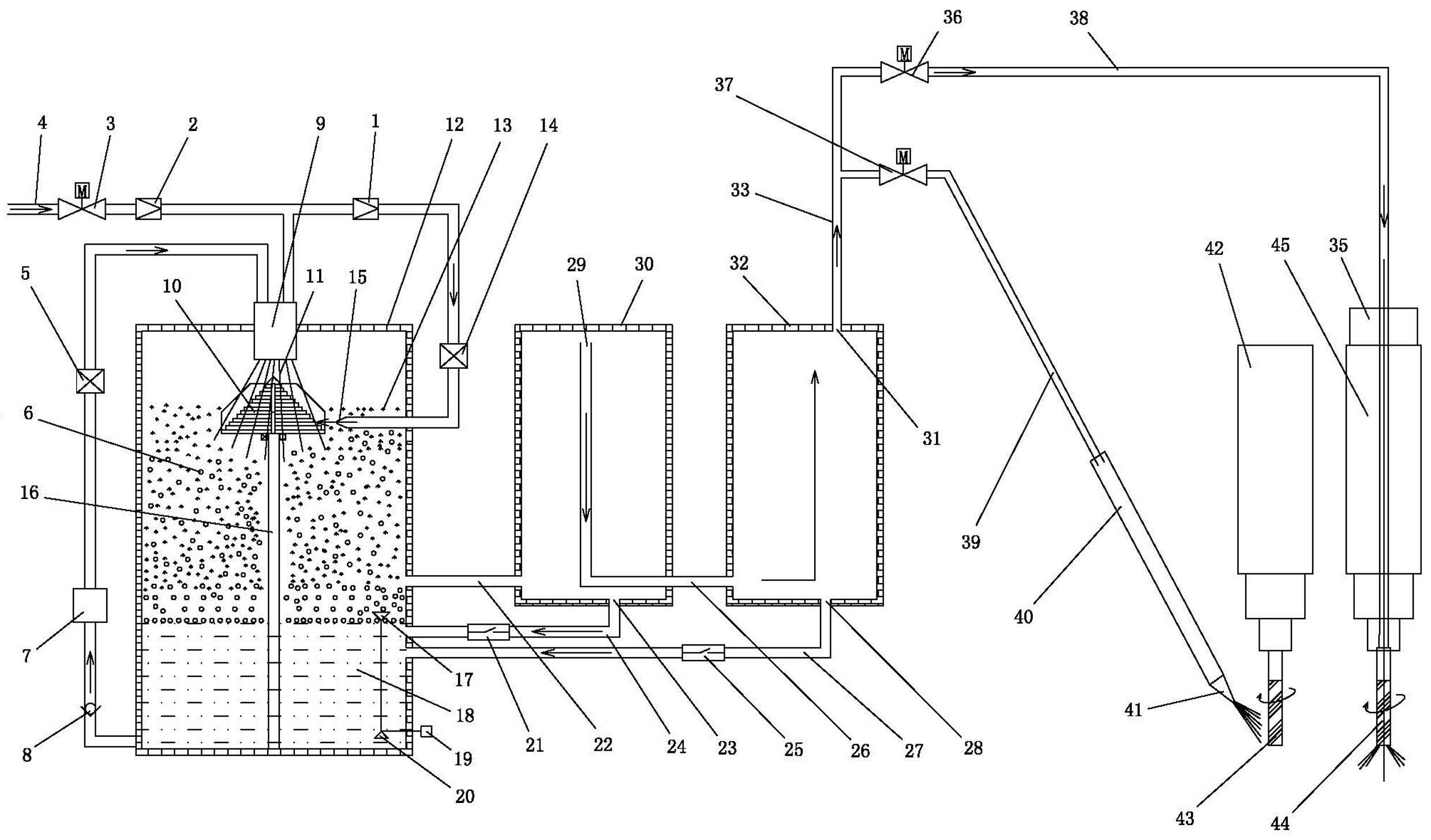

[0033] Example 1, such as figure 1 As shown, a kind of minimum quantity lubrication supply system for external cooling and internal cooling high-speed machine tool processing described in this embodiment includes:

[0034] The atomization chamber 12 equipped with cutting oil 18 is provided with a fine atomization nozzle 9 at the upper center of the inner cavity of the atomization chamber 12;

[0035] A solenoid valve 3 and filter decompression valve 2, A solenoid valve 3, filter decompression valve 2 and fine atomization nozzle 9 are connected together in sequence through gas delivery pipe 4;

[0036] The proportional pressure reducing valve 1, the A gas flow control valve 14 and the gas nozzle 15 arranged in the atomization chamber 12, the filter pressure reducing valve 2, the proportional pressure reducing valve 1, the A gas flow control valve 14 and the gas nozzle 15 are The gas delivery pipes 4 are connected together in sequence;

[0037] Oil volume control valve 5, micr...

Embodiment 2

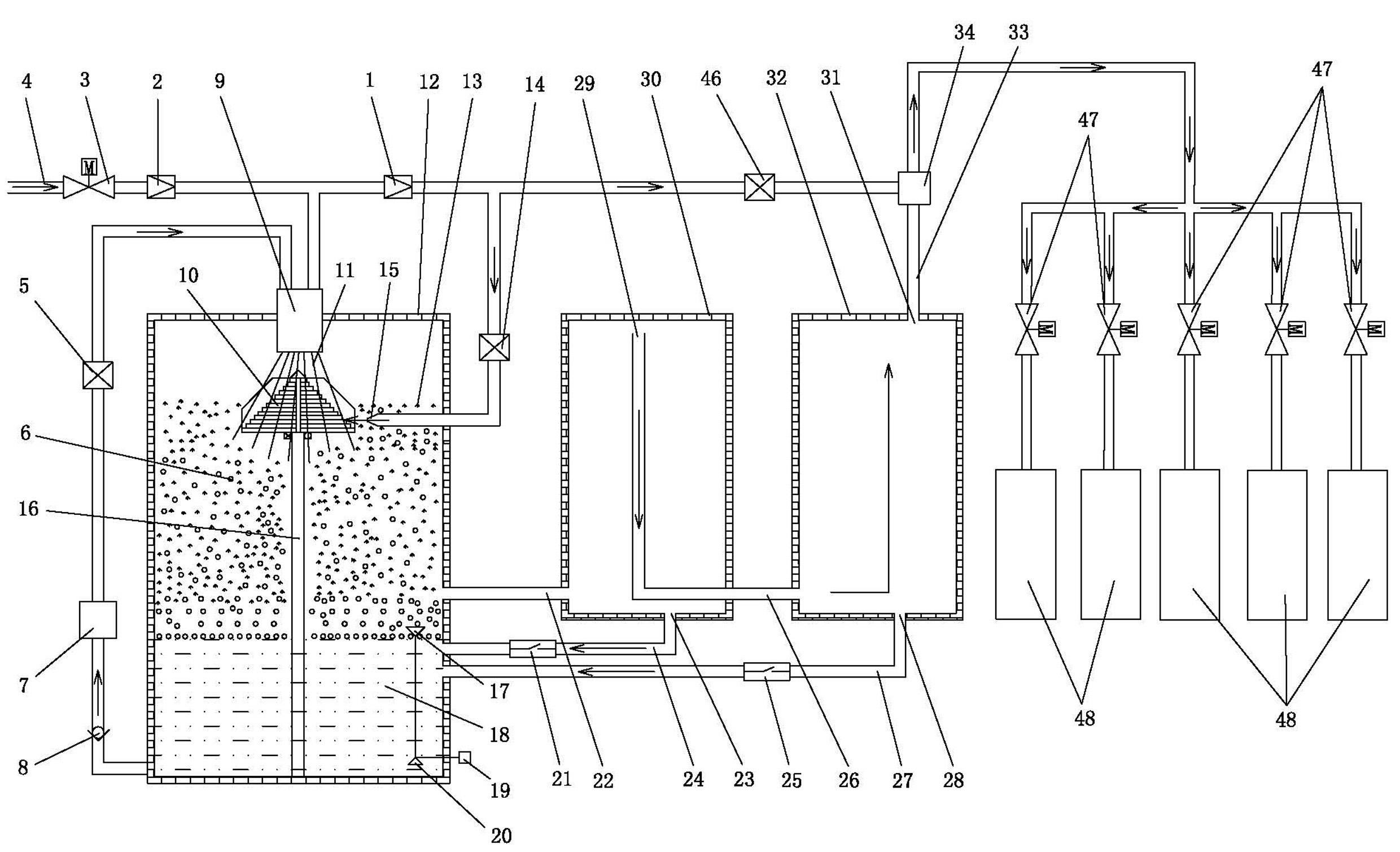

[0055] Example 2, such as figure 2 As shown, a minimal quantity lubrication supply system for external cooling and internal cooling high-speed machine tool processing described in this embodiment, compared with embodiment 1, the gas flow rate is larger and can be adjusted, suitable for oil and gas volume The demand is large, especially in the workplace where the demand for air volume is large. For example, it is used for large-scale machining centers and large-scale internal cooling drilling machines with large tool sizes, multi-station machining centers for simultaneous processing of multiple knives, CNC compound turning and milling centers, combined machine tools, and processing clusters composed of multiple machine tools. The structure different from that of Embodiment 1 in Embodiment 2 is: this embodiment also includes a B gas flow control valve 46 and a tee 34. The pipes 4 are connected together in sequence, the tee 34 is connected to the secondary sedimentation chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com