Technological method for producing artificial quartz stone checkered plates by means of placing mold in advance

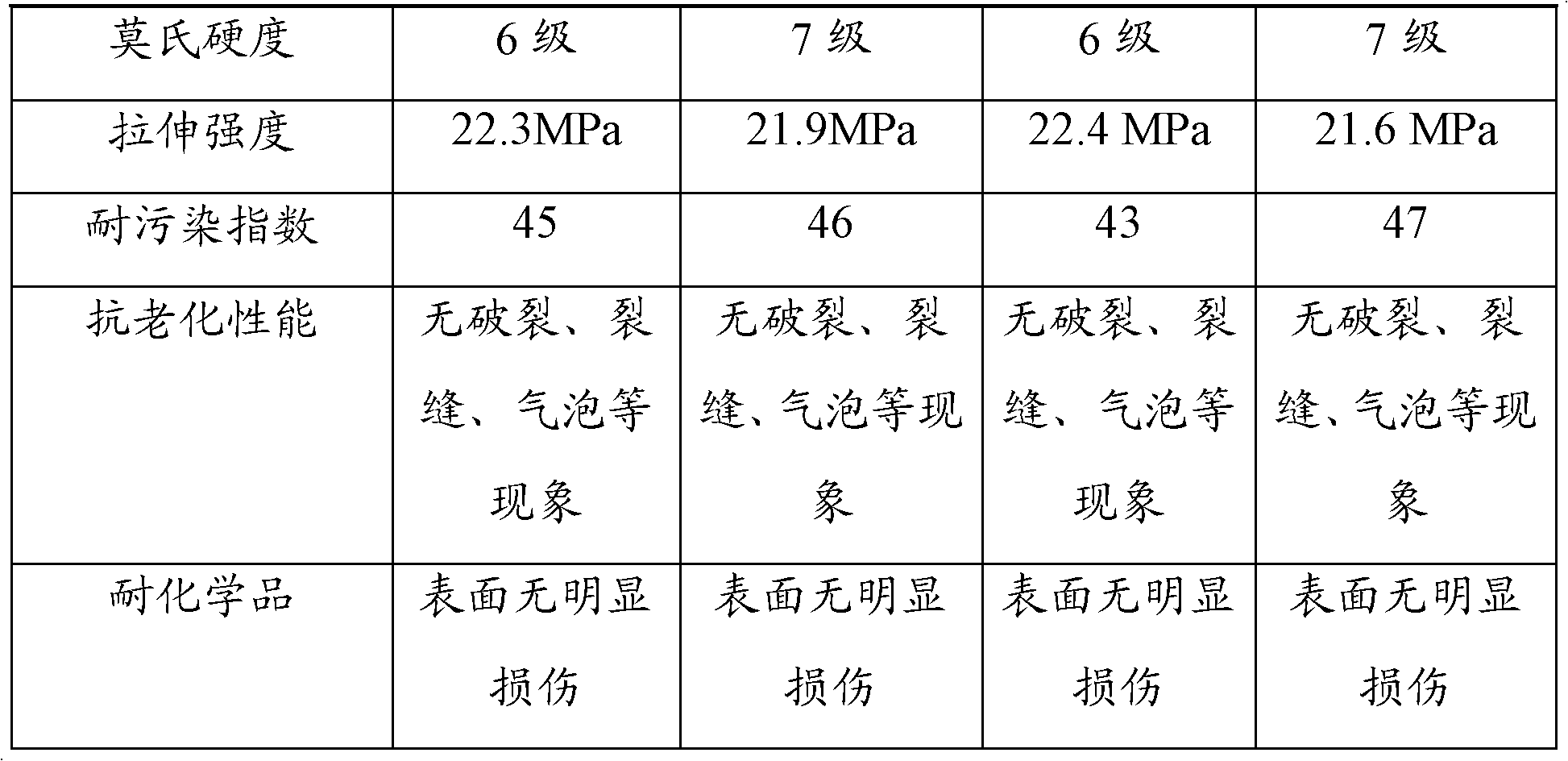

A technology of artificial quartz stone and process method, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of no pattern, simple technology, single product color, etc., achieve performance improvement such as tensile strength and hardness, realize diversity, The effect of low energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

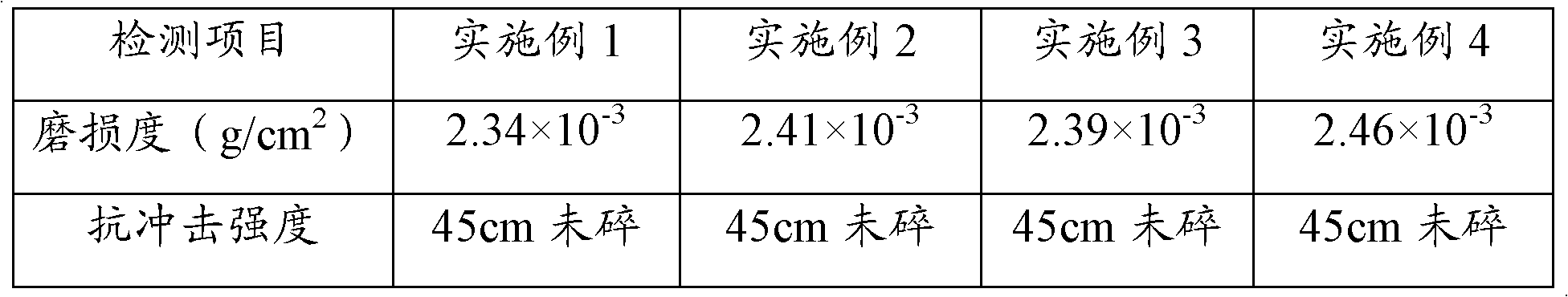

Examples

Embodiment 1

[0045] Mix 300-mesh quartz powder, a mixture of 20-mesh quartz stone and zircon, and resin color paste at a mass ratio of 70%, 20%, and 10%, and mix them evenly. According to the different colors of the resin color paste, prepare 8 groups of ingredients of different colors. Afterwards, add methyl ethyl ketone peroxide accounting for 3% of the total weight of the ingredients in each group of ingredients, and stir evenly before use; produce artificial quartz stone checkered plates according to the first method, wherein the pre-pressing time is 3 minutes, and the pressure of the press is 30 After the second cloth, it is pressed and formed under a pressure of 80 tons to obtain quartz stone pattern plates of various colors and different patterns, which are cut into standard plates after polishing.

Embodiment 2

[0047] Mix 500-mesh quartz powder, 30-mesh colored glass, and resin color paste according to the mass ratio of 90%, 2%, and 8%, and mix them evenly. Add methyl ethyl ketone peroxide, which accounts for 5% of the total weight of the ingredients, and stir it evenly before use; produce artificial quartz stone checkered plates according to the first method, wherein the pre-pressing time is 5 minutes, and the pressure of the press is 35 tons. Finally, it is pressed and formed under a pressure of 120 tons to obtain quartz stone pattern plates of various colors and patterns, which are cut into standard plates after polishing.

Embodiment 3

[0049] Mix 300-mesh quartz powder, a mixture of 20-mesh quartz stone and zircon, and resin color paste at a mass ratio of 70%, 20%, and 10%, and mix them evenly. According to the different colors of the resin color paste, prepare 8 groups of ingredients of different colors. Afterwards, add methyl ethyl ketone peroxide accounting for 3% of the total weight of the ingredients in each group of ingredients, and stir evenly before use; produce artificial quartz stone checkered plates according to the second method, wherein the pre-pressing time is 3 minutes, and the pressure of the press is 30 After the second cloth, it is pressed and formed under a pressure of 80 tons to obtain quartz stone pattern plates of various colors and different patterns, which are cut into standard plates after polishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com