Vacuum mixing injection molding system and method for membrane filter plate of filter press

A diaphragm filter plate and vacuum stirring technology, which is applied in the manufacture of filter plate injection molding systems and in the field of diaphragms, can solve problems such as diaphragm rupture, filter plate cracks, and fractures, and achieve the effect of improving the molding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

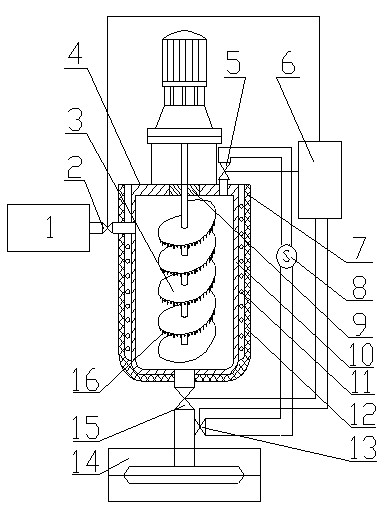

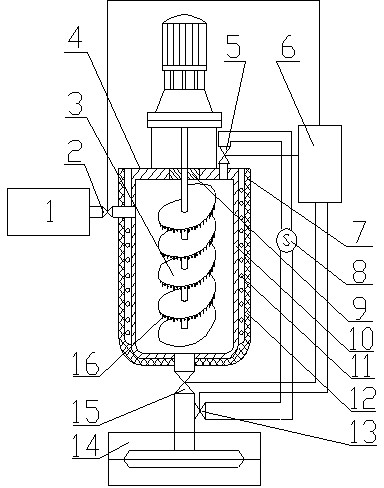

[0009] Example 1: Refer to the attached figure 1 . A vacuum stirring injection molding system for the membrane filter plate of a filter press. The discharge port of the injection molding machine 1 is connected to the vacuum agitator barrel 4 through a feeding solenoid valve 2, and the control terminal of the feeding solenoid valve 2 is connected to the signal output terminal of the controller 6 , The screw propeller stirrer 3 is located in the vacuum stirrer barrel 4 and is driven to rotate by the motor reducer located on the upper part of the vacuum stirrer barrel 4. The vacuum suction nozzle is connected to the vacuum exhauster 8 through the air solenoid valve 5 and the air pipe. The control end of the air solenoid valve 5 is connected to the signal output end of the controller 6, the discharge port of the vacuum stirrer barrel 4 is connected to one end of the three-way through the discharge solenoid valve 15, and the other end of the three-way through is directly connected t...

Embodiment 2

[0010] Embodiment 2: On the basis of embodiment 1, a vacuum forming method for filter press diaphragm or filter plate. The injection molding machine 1 injects the plastic material into the vacuum stirrer barrel 4 through the feeding solenoid valve 2. The controller 6 instructs the supply solenoid valve 2 to close, the discharge solenoid valve 15 to close, and the gas solenoid valves 5 and 13 to open. The controller 6 commands the screw propeller stirrer 3 located in the vacuum stirrer barrel 4 to stir the material at the same time. The air extractor 8 evacuates the material in the barrel 4 of the vacuum stirrer and the cavity of the diaphragm or filter plate forming mold 14. When the controller 6 detects the material and the material in the barrel 4 of the vacuum stirrer from the vacuum air extractor 8 When the vacuum of the forming cavity of the diaphragm or filter plate forming mold 14 reaches the set requirement, the gas solenoid valves 5 and 13 are instructed to close, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com