Electric power assisting device for automobile brake system

An automobile braking system and electric power assist technology, applied in the field of vehicles, can solve the problems of reducing the flexibility and stability of braking, affecting the normal operation of electric control and accessories, and complex conditions of automobile power assist devices, so as to ensure the accuracy and function The effect of uniform force and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

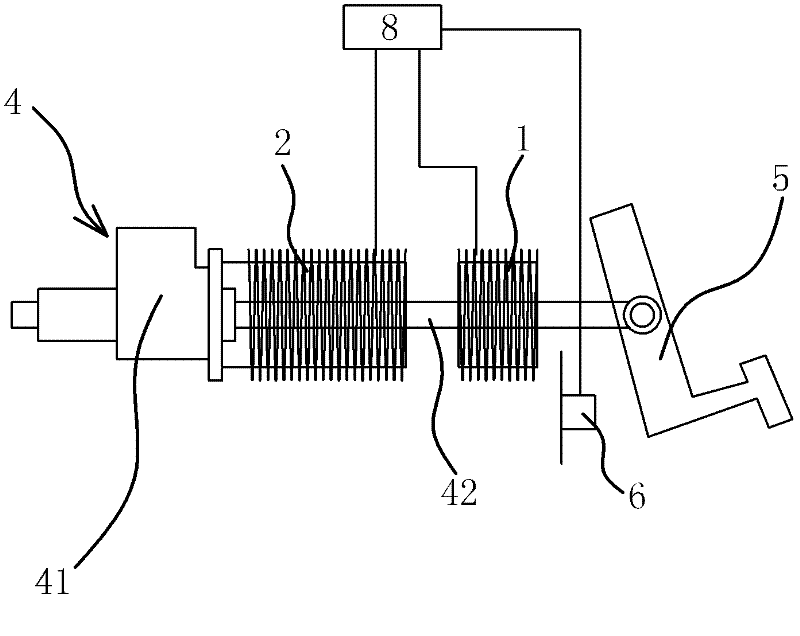

[0035] Such as figure 1 As shown, the electric booster of the automobile braking system is arranged between the brake pedal 5 and the brake master cylinder 4, and it includes an electromagnetic coil one 1, an electromagnetic coil two 2, an electronic induction unit and an ECU8.

[0036] Such as figure 1 As shown, specifically, the brake master cylinder 4 includes a cylinder body 41 fixed on the vehicle body and a push rod 42 pierced on the cylinder body 41 , the free end of the push rod 42 is hinged to the brake pedal 5 .

[0037]The electromagnetic coil one 1 is sheathed on the push rod 42 , and the electromagnetic coil one 1 is fixedly connected with the push rod 42 . The second electromagnetic coil 2 is located on one side of the first electromagnetic coil 1 , and one pole of the second electromagnetic coil 2 is opposite to one pole of the first electromagnetic coil 1 . The second electromagnetic coil 2 is fixed on the fixing part of the automobile, and the fixing part is...

Embodiment 2

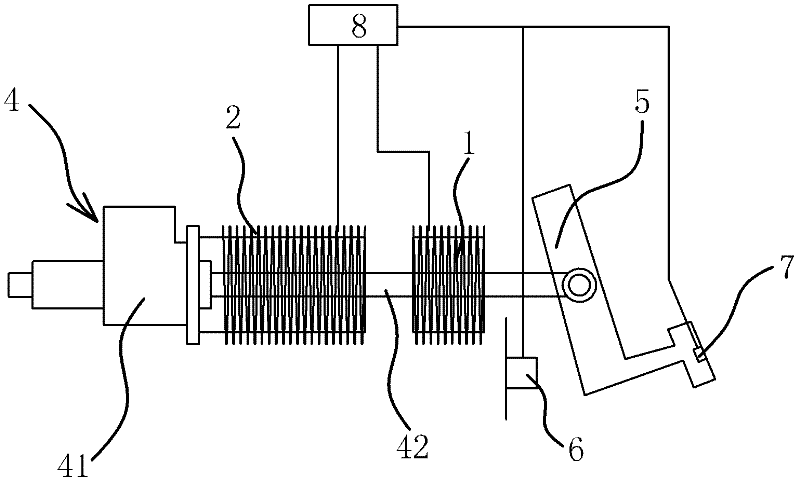

[0044] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: figure 2 As shown, the electronic sensing unit also includes a pressure sensor 7 fixed on the tread of the brake pedal 5 . The pressure applied to the tread of the brake pedal 5 by the driver is completely different when performing increased braking and canceling the braking. If there is a reduction, the above-mentioned pressure changes can be sensed by the pressure sensor 7 and generate corresponding signals to be transmitted to the ECU 8 . Simultaneously using the distance sensor 6 and the pressure sensor 7 to sense the actions of the driver can ensure the accuracy, stability and sensitivity of the sensing.

Embodiment 3

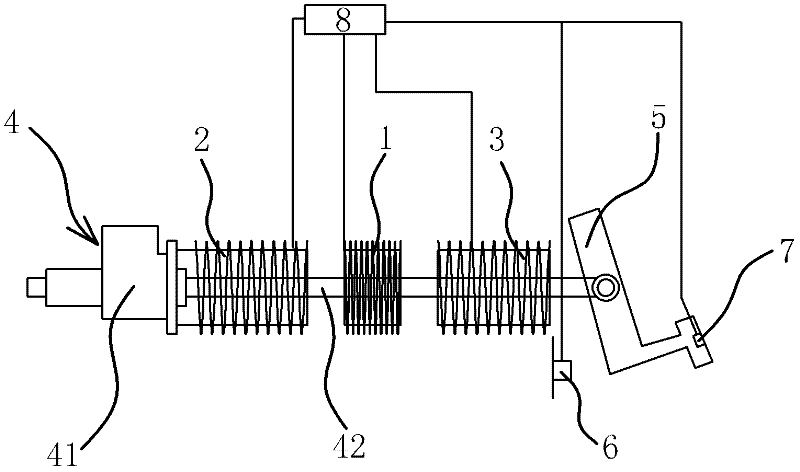

[0046] The structure and principle of the present embodiment are basically the same as those of the second embodiment, the difference is that: image 3 As shown, the electric booster also includes an electromagnetic coil three 3, one pole of the electromagnetic coil three 3 is opposite to the other pole of the electromagnetic coil one 1; The above-mentioned ECU 8 that can control the energization state of the electromagnetic coil three and three coils according to the action state of the brake pedal 5 sensed by the electronic trigger control mechanism is electrically connected. When the electromagnetic coil one 1, the electromagnetic coil two 2 and the electromagnetic coil three 3 are powered The absorption-repulsion state between one 1 and electromagnetic coil two 2 is opposite to the absorption-repulsion state between electromagnetic coil one 1 and electromagnetic coil three 3 .

[0047] Setting the electromagnetic coil three 3 can increase the force that the electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com