Trichlorosilane production method used during polycrystalline silicon production

A technology of trichlorosilane and polysilicon, which is applied in the direction of halosilane and halide silicon compounds, can solve the problems of energy consumption, high cost, and large equipment wear, and achieve the goal of reducing equipment investment, reducing burden, and increasing operating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

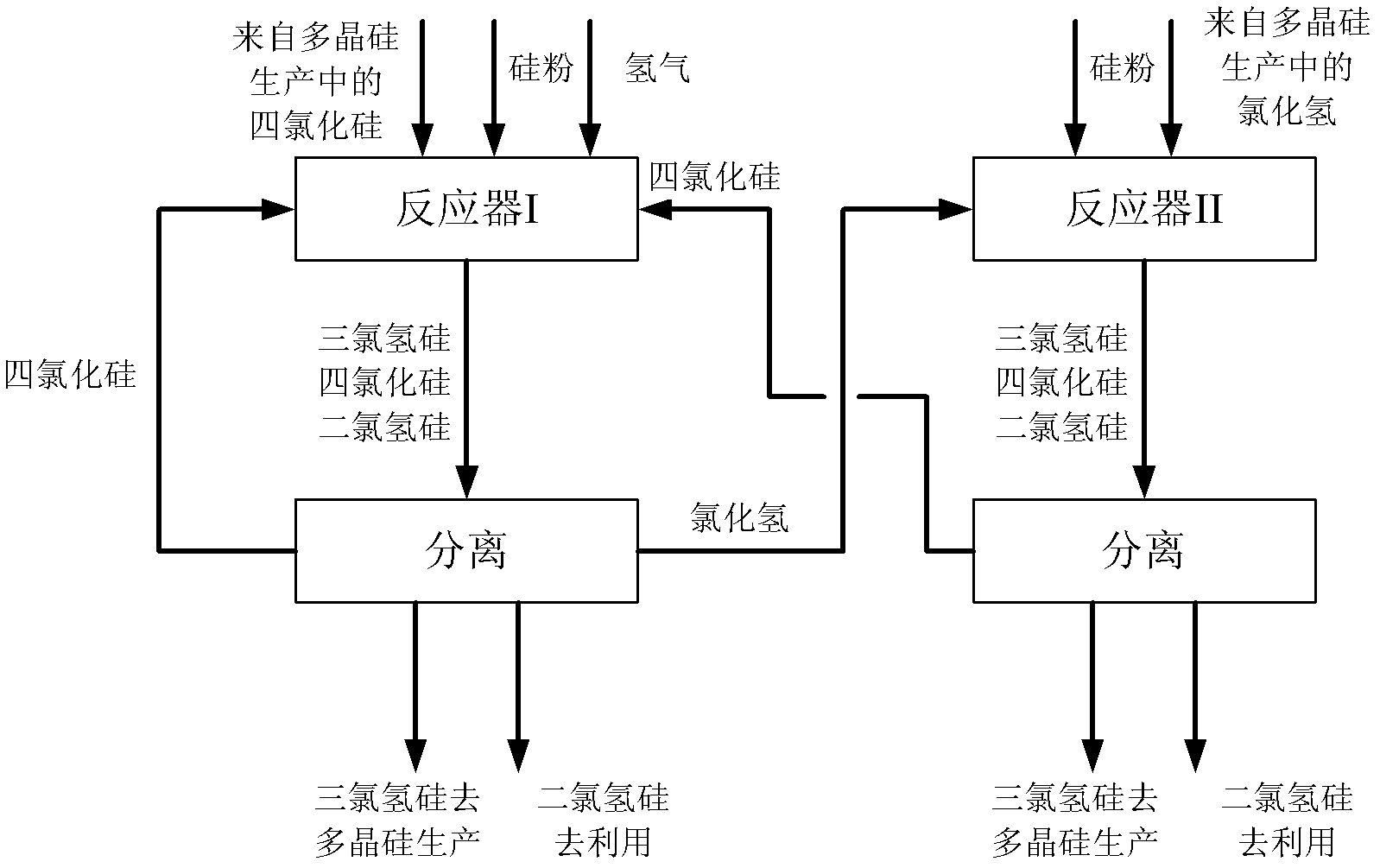

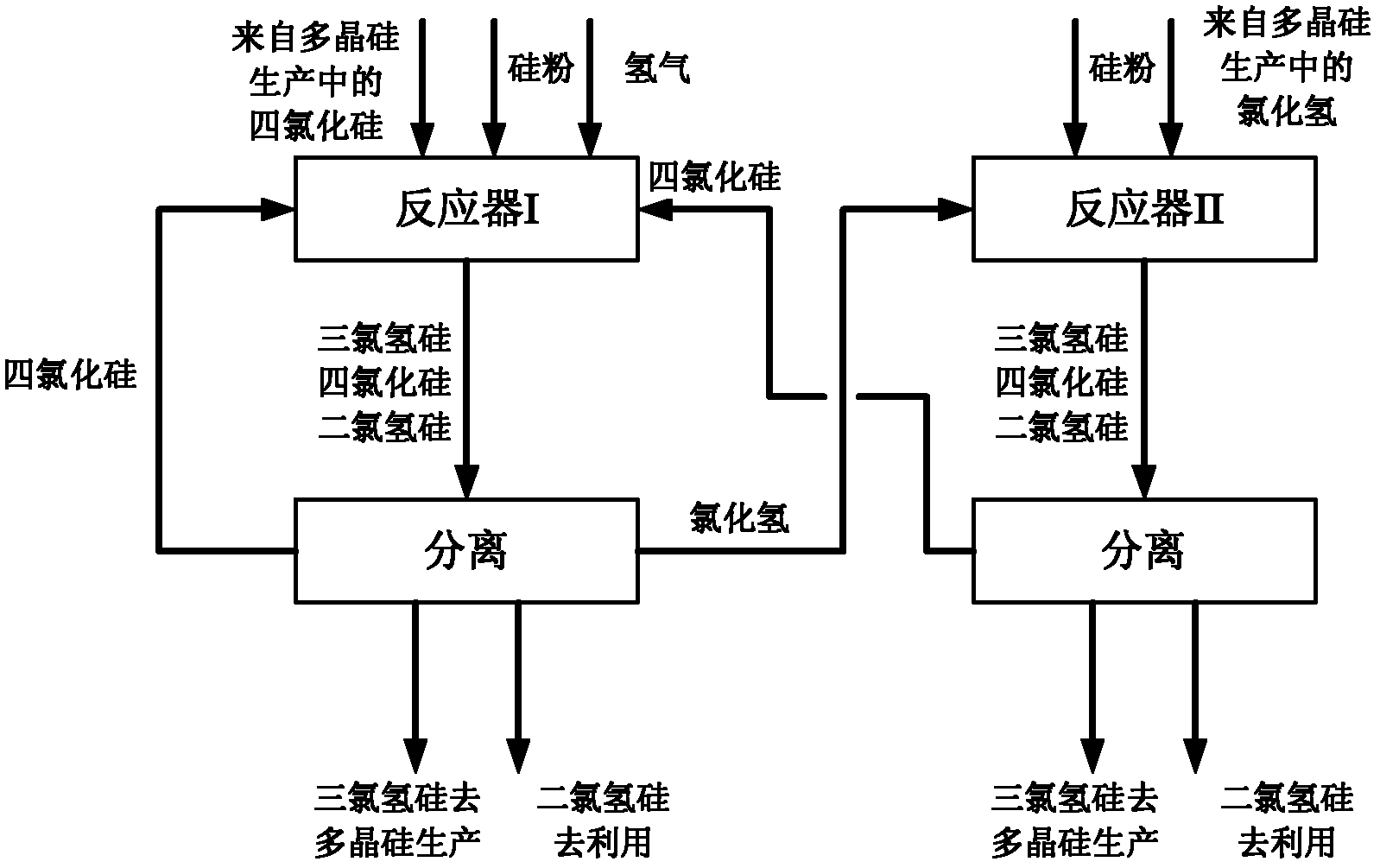

[0036] A kind of manufacture method of trichlorosilane, the steps are as follows:

[0037]Hydrogen from the polysilicon production system, supplementary fresh hydrogen, industrial silicon powder and relatively pure silicon tetrachloride from polysilicon production enter the reactor I, the reaction temperature is 520°C, the reaction pressure is 3.5MPa, and the gas phase flow rate is 0.1m The reaction is carried out under the condition of / s to generate silicon tetrachloride, trichlorosilane and a small amount of dichlorosilane and hydrogen chloride. The conversion rate of silicon tetrachloride into trichlorosilane is 23.5%. After the product is dedusted and preliminarily separated under reduced pressure, silicon tetrachloride is cyclically reacted, trichlorosilane is sent to produce polysilicon, hydrogen chloride is sent to react with silicon powder, and the utilization of dichlorosilane is not within the scope of this patent. Industrial silicon powder, hydrogen chloride obtai...

Embodiment 2

[0039] A kind of manufacture method of trichlorosilane, the steps are as follows:

[0040] Hydrogen from the polysilicon production system, supplementary fresh hydrogen, industrial silicon powder, and relatively pure silicon tetrachloride from polysilicon production enter the reactor I. The reaction temperature is 550°C, the reaction pressure is 3.8MPa, and the gas phase flow rate is 0.5m The reaction is carried out under the condition of / s to generate silicon tetrachloride, trichlorosilane and a small amount of dichlorosilane and hydrogen chloride. The conversion rate of silicon tetrachloride into trichlorosilane is 25.2%. After the product is dedusted and preliminarily separated under reduced pressure, silicon tetrachloride is cyclically reacted, trichlorosilane is sent to produce polysilicon, hydrogen chloride is sent to react with silicon powder, and the utilization of dichlorosilane is not within the scope of this patent. Industrial silicon powder, hydrogen chloride obt...

Embodiment 3

[0042] A kind of manufacture method of trichlorosilane, the steps are as follows:

[0043] Hydrogen from the polysilicon production system, supplemented fresh hydrogen, industrial silicon powder and relatively pure silicon tetrachloride from polysilicon production enter the reactor I. The reaction temperature is 580°C, the reaction pressure is 4.5MPa, and the gas phase flow rate is 1m / The reaction is carried out under s conditions to generate silicon tetrachloride, trichlorosilane and a small amount of dichlorosilane and hydrogen chloride. The conversion rate of silicon tetrachloride into trichlorosilane is 27.1%. After the product is dedusted and preliminarily separated under reduced pressure, silicon tetrachloride is cyclically reacted, trichlorosilane is sent to produce polysilicon, hydrogen chloride is sent to react with silicon powder, and the utilization of dichlorosilane is not within the scope of this patent. Industrial silicon powder, hydrogen chloride obtained from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com