Drum ammoniation granulating machine

A drum granulator and granulator technology, applied in the direction of fertilizer mixture, fertilizer form, fertilization device, etc., can solve the problems of unsatisfactory quality, poor granule appearance, low ball forming rate, etc., and improve production capacity , reduce the degree of re-granulation, reduce the effect of evaporation water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

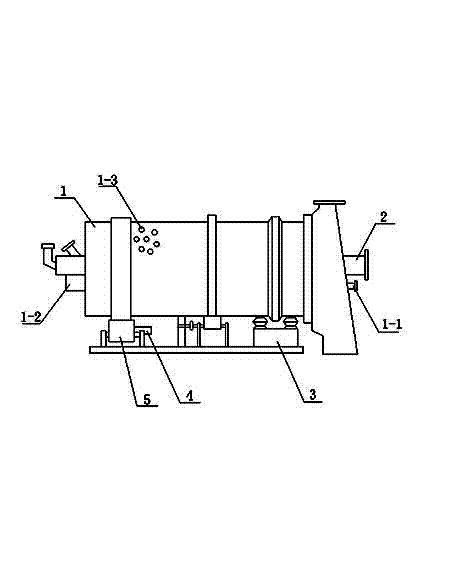

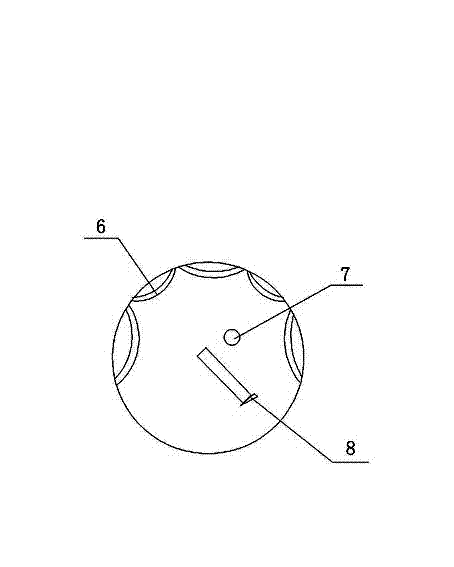

[0011] Such as figure 1 As shown, the present invention includes a drum granulator, and the drum granulator is mainly composed of a cylinder body 1, a retaining wheel group 3, a driving device 4 and a supporting wheel group 5, and it also has a pipe beam 2 and a group of flexible glue Plate 6, slurry sprayer 7 and ammonia distributor 8, ammonia gas inlet 1-1, slurry inlet 1-2 and material return port 1-3 are respectively provided at both ends of cylinder body 1, and a group of flexible rubber plates 6 are respectively Installed on the inner wall circumference of the cylinder 1 in sequence, the cylinder 1 is provided with a plurality of breathing holes 1-3, the pipe beam 2 is installed in the cylinder 1, the slurry sprayer 7 is installed on the pipe beam 2, and the ammonia distributor 8 is installed on the pipe beam 2, a retaining ring 1-1 is provided in the cylinder body 1, the slurry sprayer 7 communicates with the slurry inlet 1-2 through the slurry pipe, and the ammonia dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com