Chlorinated polyvinyl chloride tube and preparation process thereof

A chlorinated polyvinyl chloride, pipe technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of decreased strength, double bond breakage, poor weather resistance, etc., to improve aging resistance, improve impact strength, tensile strength The effect of high tensile yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

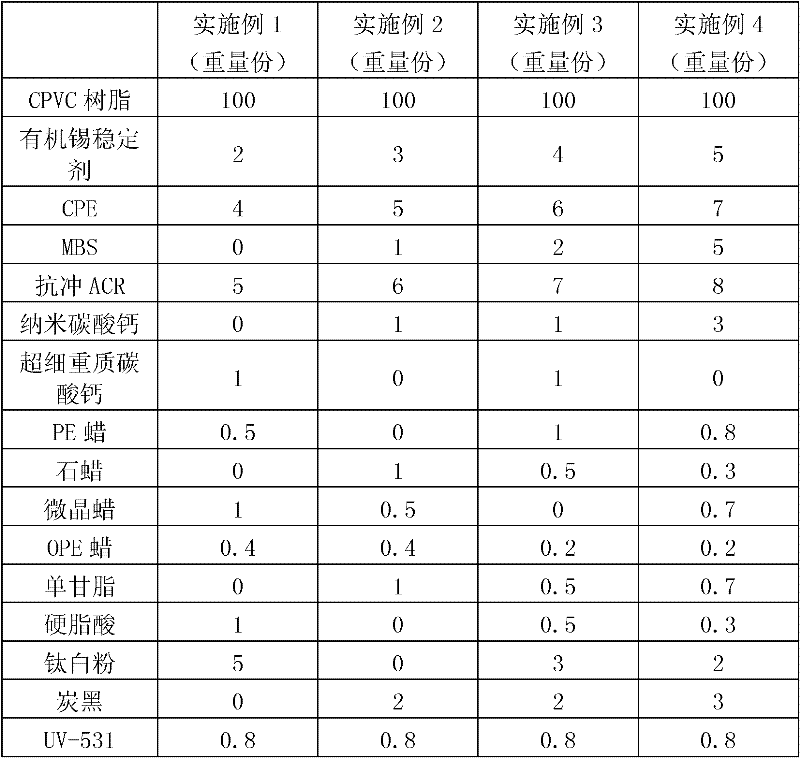

[0040] A kind of chlorinated polyvinyl chloride pipe, the formula is shown in Table 1;

[0041] The preparation method comprises the following steps:

[0042] (1) Take each raw material according to the formula quantity, put chlorinated polyvinyl chloride resin, stabilizer, toughening agent, filler, lubricant, light shielding agent, ultraviolet light absorber in a high-speed mixer at 105 ± 5 ℃ and mix well, and keep in this temperature range for 10 minutes;

[0043] (2) Put the above mixture into a 40±5°C cold mixer and mix for 10 minutes, then put the mixture into the drying silo;

[0044] (3) Extrude the compound in the drying silo with a conical twin-screw extruder, and the process parameters are selected as follows:

[0045] ① Twin-screw extruder barrel:

[0046] (I) Zone 175-210°C

[0047] (II) Zone 175-200℃

[0048] (III) Zone 170-200℃

[0049] (IV) Zone 170-190°C

[0050] (V) Zone 160-180°C

[0051] Merge core 150-180℃

[0052] ②Twin-screw extruder screw oil te...

Embodiment 2

[0063] The formula is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

[0065] The formula is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com