Method for supercritical extraction of sea buckthorn oil

A supercritical and seabuckthorn oil technology, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of supercritical equipment blockage, poor fluidity of lipid substances, and no formation of free unsaturated fatty acids, so as to improve utilization efficiency and ensure The effect of using safety and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

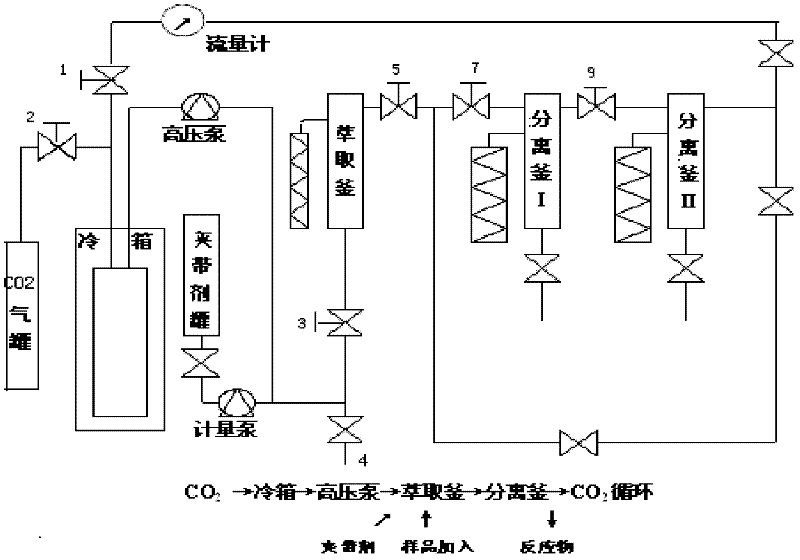

Embodiment 1

[0029] After 10kg of fresh seabuckthorn fruit is mixed with an equal volume of water, minced and homogenized, place it in an incubator and add 250U protease and 450U lipase to the homogenate (protease and lipase can be purchased from Changsha Xiangzi Biotechnology Co., Ltd.) , keep warm at 40°C for 10 h, put the enzymolysis solution in a 30L barrel, put it into the extraction kettle, install the pressure ring and sealing ring, tighten the plug, then turn on the freezer, put the extraction kettle, Adjust the temperature controllers of separation kettle Ⅰ and separation kettle Ⅱ to the required temperature respectively; when the temperature of the refrigerator drops to about 0°C, the extraction kettle and separation kettle Ⅱ respectively reach 45°C, and the temperature of separation kettle Ⅰ reaches 50°C, Open the cylinder, open valve 2 (CO 2 Liquefied in the cold cycle), then turn on the high-pressure pump to pressurize, when the extraction pressure of the extraction kettle rea...

Embodiment 2

[0033] Mix 100kg of fresh seabuckthorn fruit with an equal volume of water, mince and homogenize it, put it in an incubator, add 3000U protease and 5000U lipase to the homogenate, keep it warm at 40°C for 10 hours, and put its enzymolysis solution in 300L Put it into the extraction kettle, install the pressure ring and sealing ring, tighten the upper plug, then turn on the refrigerator, and adjust the temperature controllers of the extraction kettle, separation kettle Ⅰ, and separation kettle Ⅱ to the required settings. After the temperature of the refrigerator drops to about 0°C, the temperature of the extraction kettle and the separation kettle II reaches 45°C, and the temperature of the separation kettle I reaches 50°C, open the gas cylinder and open the valve 2 (CO 2 Liquefied in the cold cycle), then turn on the high-pressure pump to pressurize, when the extraction pressure of the extraction kettle reaches 35MPa, adjust the shut-off valve to balance the pressure of the ext...

Embodiment 3

[0035] Mix 200kg of fresh seabuckthorn fruit with an equal volume of water, mince and homogenize it, put it in an incubator, add 5500U protease and 9000U lipase to the homogenate, keep it warm at 40°C for 10 hours, and put its enzymolysis solution in 300L Put it into the extraction kettle, install the pressure ring and sealing ring, tighten the upper plug, then turn on the refrigerator, and adjust the temperature controllers of the extraction kettle, separation kettle Ⅰ, and separation kettle Ⅱ to the required settings. After the temperature of the refrigerator drops to about 0°C, the temperature of the extraction kettle and the separation kettle II reaches 45°C, and the temperature of the separation kettle I reaches 50°C, open the gas cylinder and open the valve 2 (CO 2 Liquefied in the cold cycle), then turn on the high-pressure pump to pressurize, when the extraction pressure of the extraction kettle reaches 35MPa, adjust the shut-off valve to balance the pressure of the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com