Composite multi-frequency-band vibration isolation trench for building

A composite, multi-band technology, used in buildings, building components, protection devices, etc., to achieve the effects of comprehensive performance, simple structure and reasonable combination of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

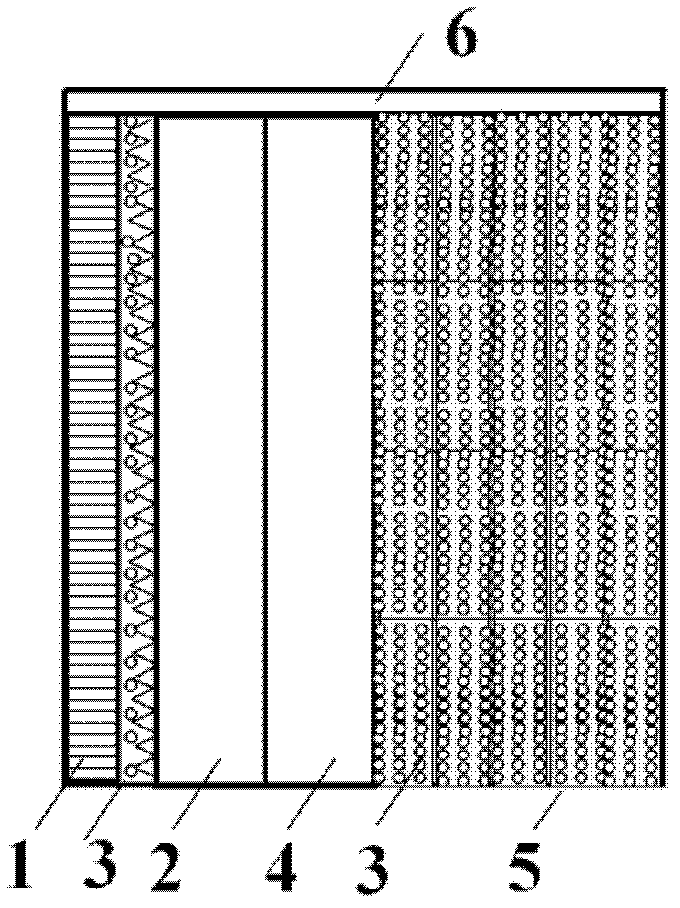

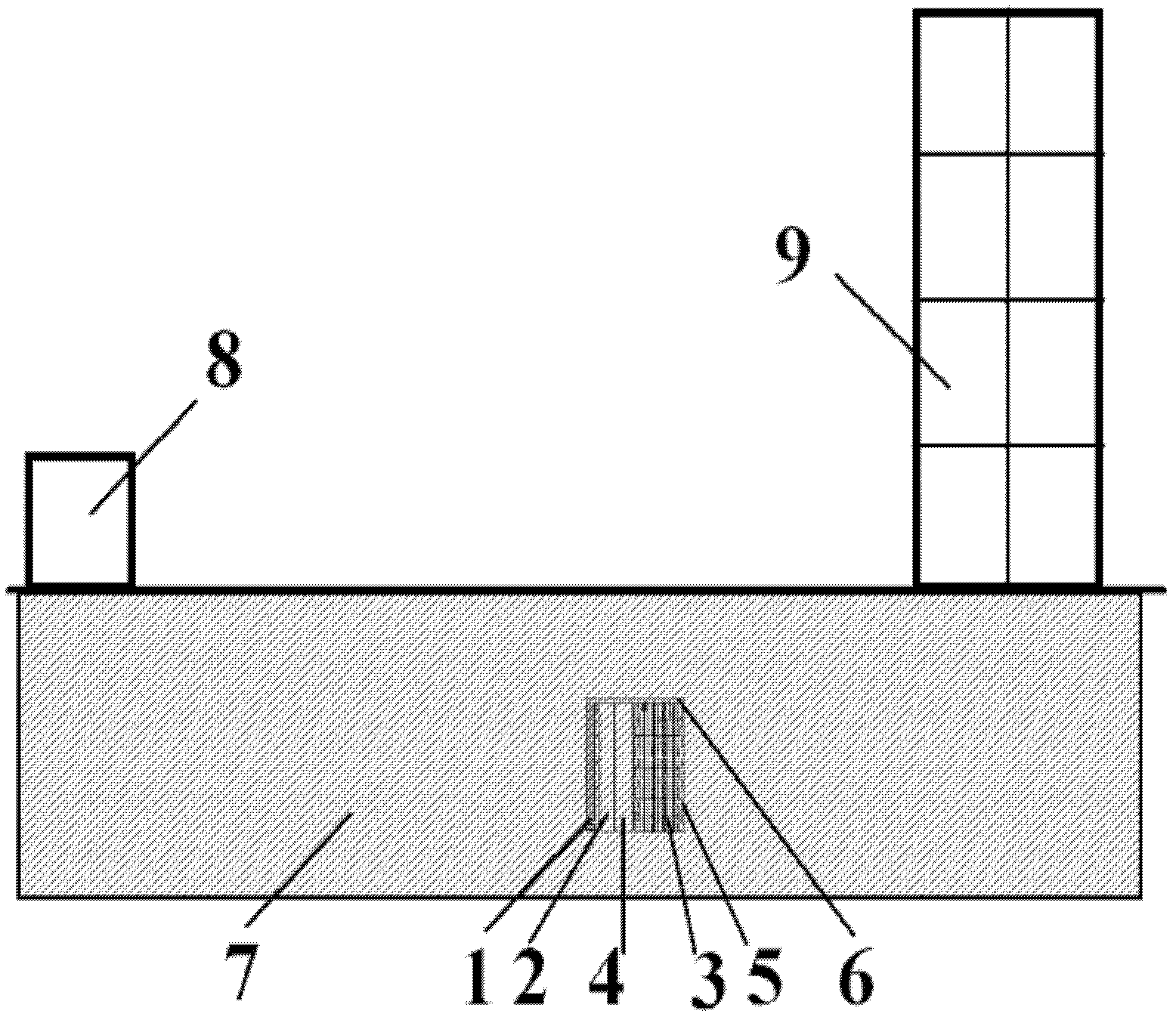

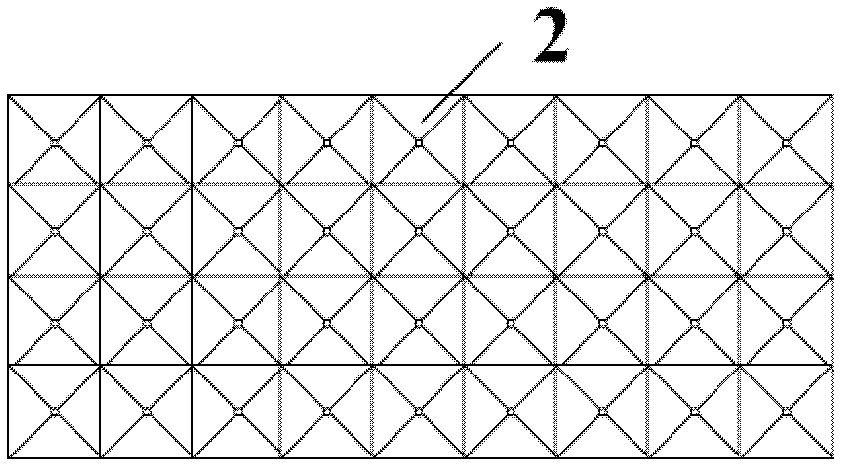

[0032] Such as figure 2 As shown, a 20-storey high-rise building is located 50m away from the main line of the urban light rail transit, and is seriously affected by the environmental vibration of the traffic system. -3 m / s 2 , the amplitude of vibration acceleration on the top floor of the building is 1.41×10 -2 m / s 2 . In order to reduce the vibration amplitude, the composite multi-band vibration isolation ditch for buildings of the present invention is used for vibration reduction and isolation. First, determine the specific location and size of the excavated vibration isolation ditch on the open space on the side of the high-rise building facing the vibration source. The vibration isolation ditch is 10m away from the outer surface of the building, with a width of 5m and a height of 6m. The depth from the top to the surface is 5m, and the total longitudinal length is 60m. Secondly, determine the detail size of each part of the vibration isolation trench. Among them, ...

Embodiment 2

[0034] Such as figure 2 As shown, a certain ancient building is located 200m away from the main line of the urban subway, which is seriously affected by the environmental vibration of the traffic system, which is not conducive to the protection of cultural relics. When the train passes by, the surface vibration acceleration amplitude of the ancient building is 3.1×10 -3 m / s 2 , the vibration acceleration amplitude of the indoor floor of the ancient building is 8.82×10 -3 m / s 2 . In order to reduce the vibration amplitude, the composite multi-band vibration isolation ditch for buildings of the present invention is used for vibration reduction and isolation. First, determine the specific location and size of the excavated vibration isolation ditch in the open space around the ancient building. The vibration isolation ditch is 25m away from the outer surface of the building, with a width of 4m and a height of 5m. The depth from the top to the surface is 5m. The plane is cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com