Numerical control alternating current permanent magnet servo variable speed variable quantity awry plate type axial plunger hydraulic motor pump

A hydraulic motor and swash plate technology applied in the field of hydraulic power devices to achieve high energy conversion efficiency, low noise, and compact structure

Inactive Publication Date: 2012-07-04

YANSHAN UNIV

View PDF7 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, judging from the current research results and literature at home and abroad, the research on the integration of the hydraulic pump and the electric motor is only to arrange the hydraulic pump and the electric motor axially on the same axis and share the same shell, and there is no overhanging shaft. volume, but it does not really achieve a high degree of integration of hydraulic pumps and electric motors

In some special occasions are still restricted

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

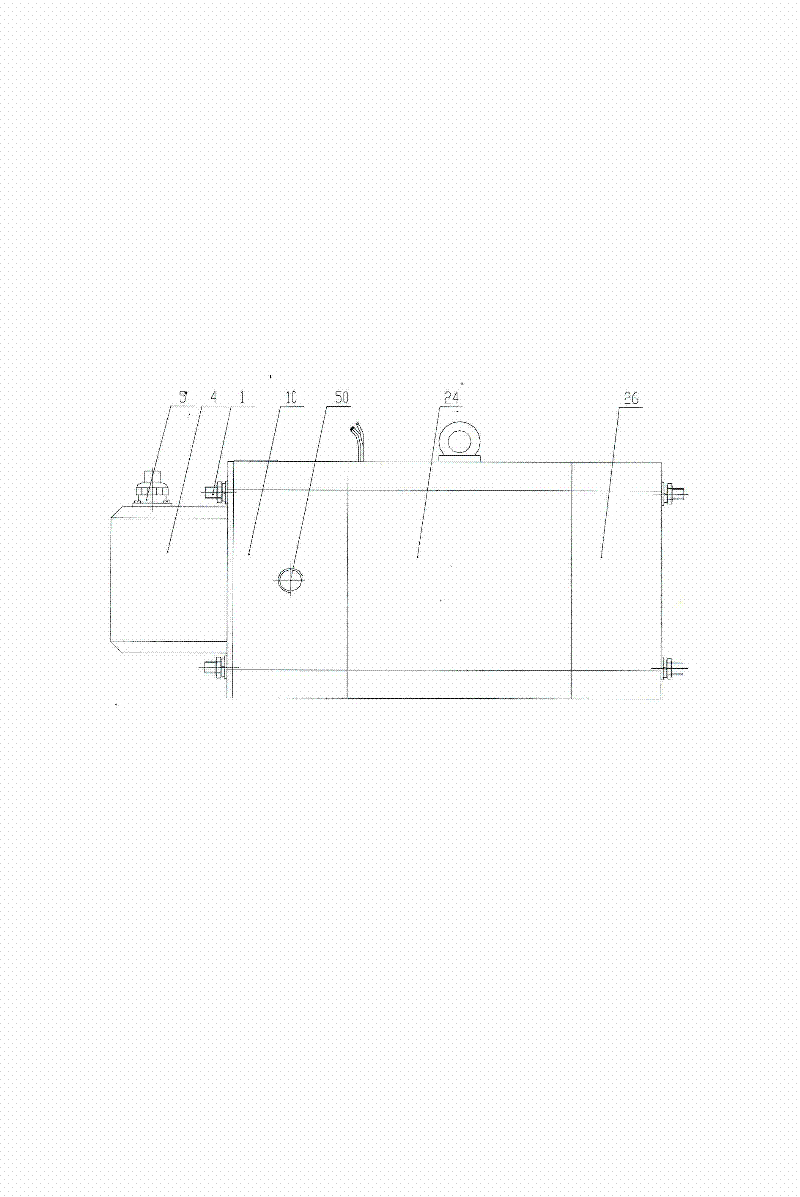

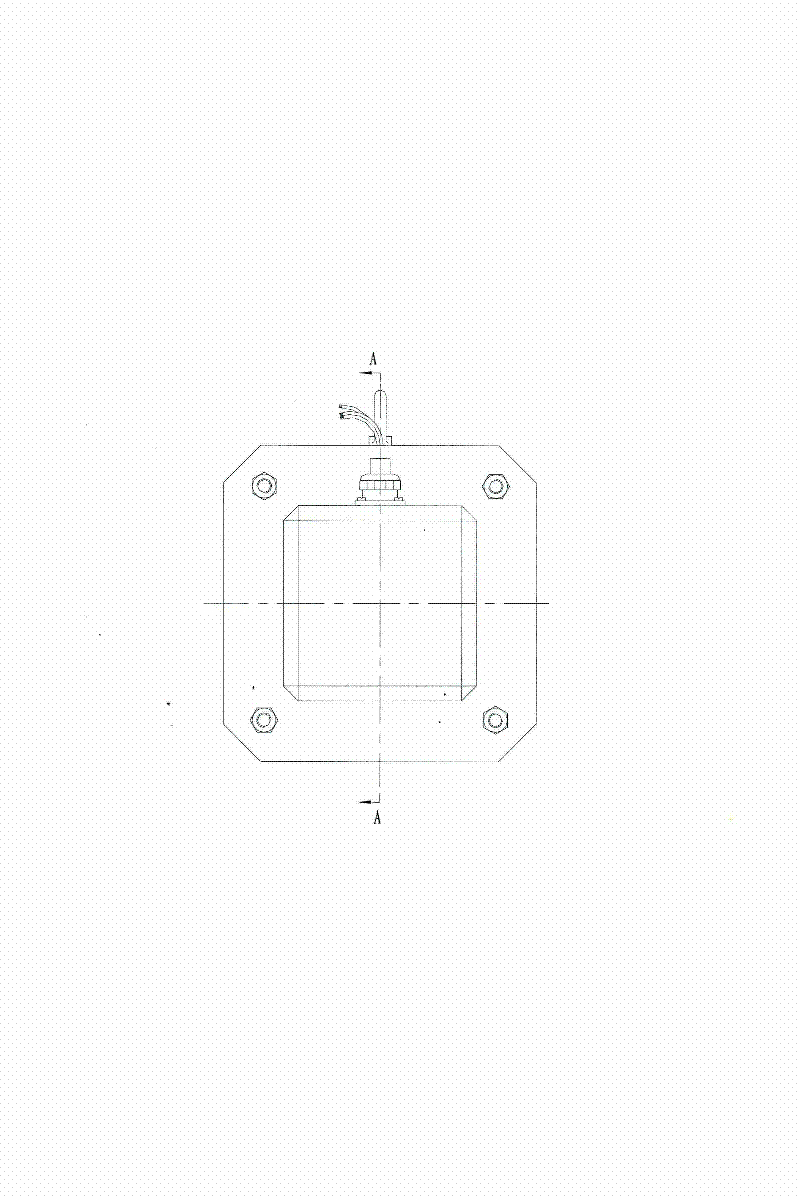

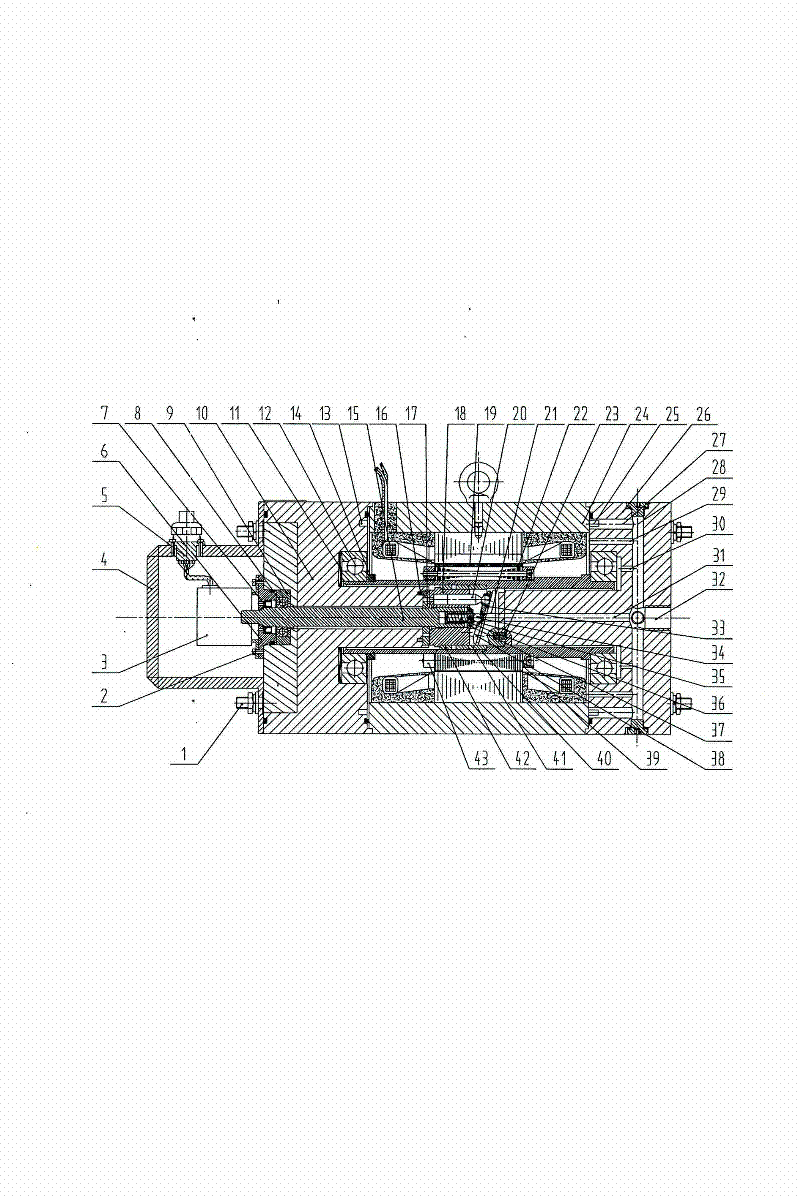

Provided is a numerical control alternating current permanent magnet servo variable speed variable quantity awry plate type axial plunger hydraulic motor pump. An oil suction port end cover and an oil drain port end cover are respectively installed at two ends of a stator, runners are respectively arranged on the oil suction port end cover, the oil drain port end cover and the stator to form passages, a rotor is installed in the stator, and the rotor is composed of a rotor core, permanent magnets, a pump sleeve, a cylinder, a right shaft key sleeve and a left shaft key sleeve. Four permanent magnets are embedded on the rotor core, the pump sleeve is sleeved inside the rotor core and supported by bearings on the oil suction port end cover and the oil drain port end cover, the right shaft key sleeve is installed inside the pump sleeve, the left shaft key sleeve is installed outside the cylinder, and rectangular teeth on the left shaft key sleeve are meshed with rectangular teeth on the right shaft key sleeve. The cylinder is installed with the left shaft key sleeve together, seven plungers hinged to piston shoes on a return stroke disc are arranged on the cylinder, the piston shoes are placed in seven holes on the return stroke disc, and the piston shoes are tightly pressed on an awry plate through an inner sleeve, a steel ball, the return stroke disc and a return stroke spring, and the awry plate is installed on the oil suction port end cover. One end of a rotate speed output shaft is supported by the bearing on the oil drain port end cover, the other end of the rotate speed output shaft is inserted in a pattern groove in the cylinder to be connected with the center of the cylinder, an inner hole is arranged on the rotate speed output shaft, a sleeve cup is installed in the hole, a movable inner sleeve is installed in the sleeve cup, the inner sleeve is contacted with the return stroke disc through the steel ball, the return stroke spring is installed between the sleeve cup and the inner sleeve, and the steel ball abuts against the return stroke disc to enable the piston shoes to be pressed on the awry plate. A thrust plate is installed on the oil drain port end cover.

Description

Technical field [0001] The invention relates to a hydraulic power device which adopts a highly integrated AC permanent magnet servo motor and a swash plate axial hydraulic pump, in particular to a numerical control AC permanent magnet servo variable speed variable swash plate axial plunger hydraulic motor pump. Background technique [0002] A hydraulic pump is an energy conversion device that converts mechanical energy into hydraulic energy. It is a power element in a hydraulic transmission system and provides a certain pressure and flow of oil for the system. At present, the hydraulic pump used in the hydraulic system is connected to the prime mover through a coupling, and the most commonly used prime mover is an electric motor. The motor is equipped with a fan due to the need for heat dissipation, which has the problem of generating noise and consuming motor energy; the coupling inevitably has the problem of misalignment when connecting the pump shaft and the motor shaft, whic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04B17/03F04B49/06

Inventor 高殿荣王志强温茂森迟冰

Owner YANSHAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com