Wear-resistant chain

A chain and wear-resistant layer technology, applied in the field of chains, can solve the problems of pin shaft surface wear, pin shaft wear, dependence on imports, etc., and achieve the effects of improving corrosion resistance, increasing service life, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

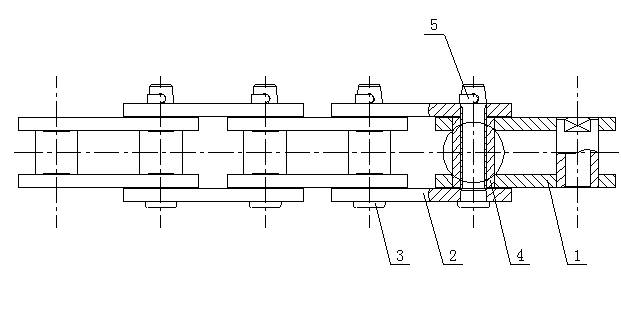

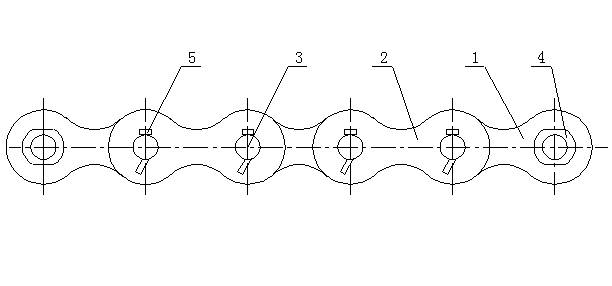

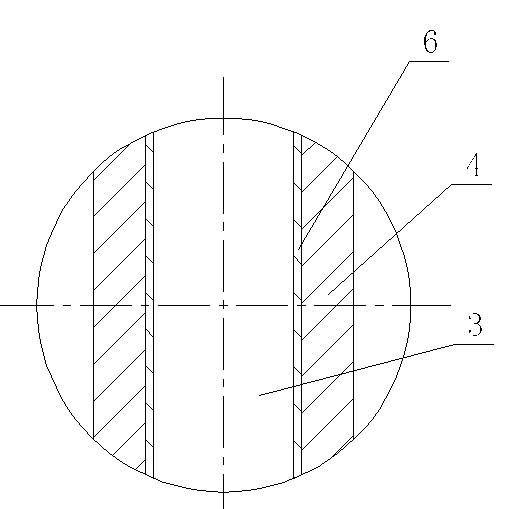

[0014] The present invention is described below in conjunction with accompanying drawing.

[0015] as attached Figure 1-3 The shown wear-resistant chain of the present invention includes an inner chain plate 1, an outer chain plate 2, a pin shaft 3, a sleeve 4 and a locking member 5; the inner chain plate 1 and the outer chain plate 2 pass through The pin shafts 3 are connected together; the pin shaft 3 is provided with a sleeve 4; the outer chain plate 2 is provided with a locking member 5 for fixing the pin shaft 3; the surface of the pin shaft 3 is provided with a wear-resistant layer 6 ; The wear-resistant layer 6 is an alloy coating; the alloy coating is a hard chrome layer.

[0016] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0017] In the wear-resistant chain of the present invention, since the surface of the pin shaft is provided with a wear-resistant layer, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com