Grill fixing method and support frame

A fixing method and technology for a barbecue grill, which are applied in the field of support frames, can solve the problems of deformation of support feet of the grill, cannot be fixed well, occupy a large space, etc., and achieve the effects of reducing transportation costs, avoiding contact, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

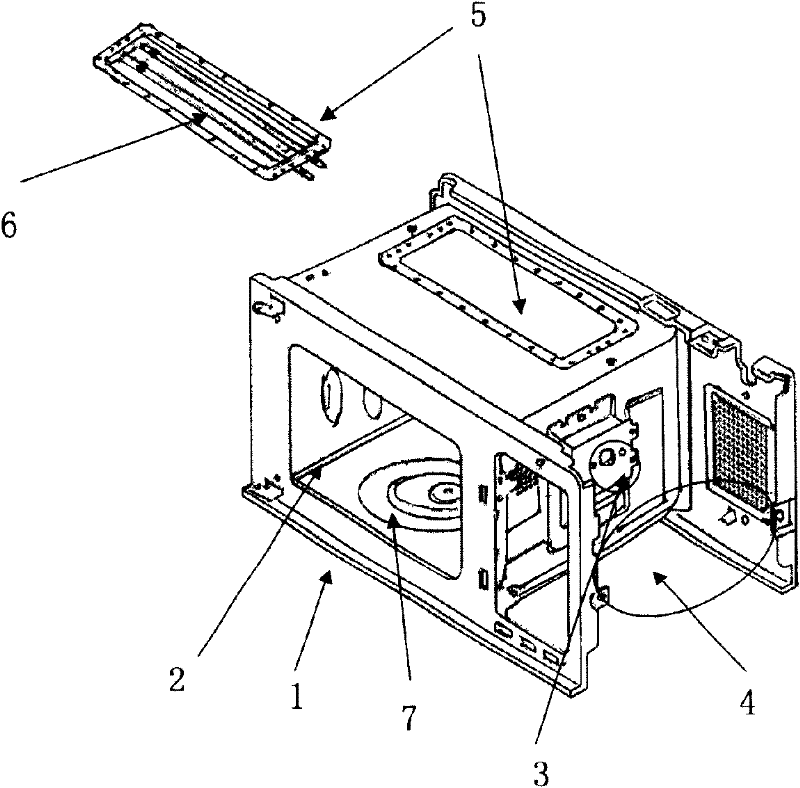

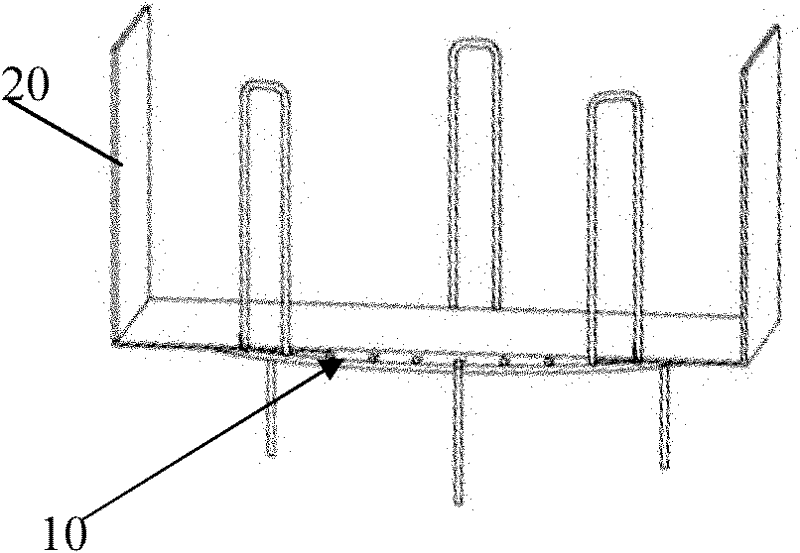

[0025] The first embodiment: In order to enhance the space utilization rate during packaging and avoid the deformation of the support legs of the barbecue grill due to extrusion, the support frame of the present invention is fixed by two pieces of cardboard, and the length of the cardboard matches the depth of the cooking chamber of the microwave oven , to prevent it from moving back and forth. Through holes matching the long support legs and the short support legs are respectively opened on the cardboard, and creasing lines are provided along both sides thereof. The fixing method of barbecue grill of the present invention will be simply described below:

[0026] First, insert the supporting legs of the grill into the corresponding through holes of the cardboard. At this time, the two cardboards clamp the supporting surface of the grill between them. Bending down to form a wing structure, and then sending the grill and the cardboard together into the cooking chamber of the mi...

no. 2 example

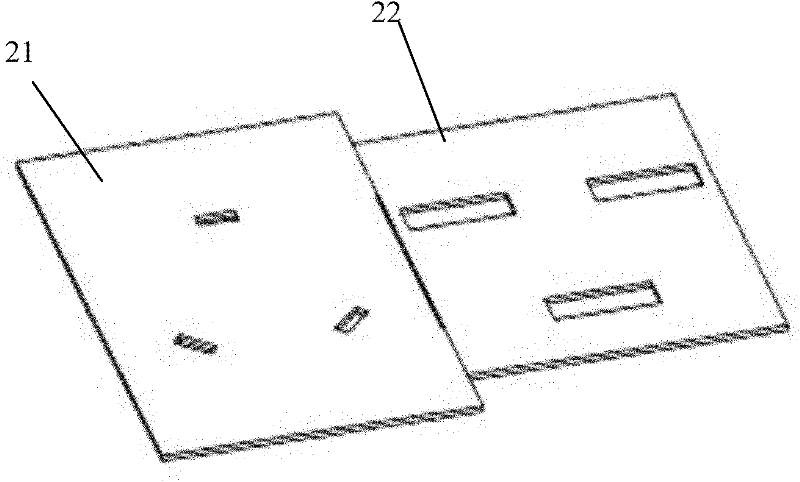

[0028] The second embodiment: In order to improve the assembly efficiency and avoid the efficiency drop caused by the separation of the two cardboards, the two cardboards in the second embodiment of the present invention are integrally formed, with a creasing line in the middle, and on both sides of the creasing line Matching through holes are provided correspondingly. When assembling, one side of a grill is firstly installed, then the cardboard is bent and the other side is put into it, and then the wing is formed by bending and put into the cooking cavity of the microwave oven.

[0029] It should be pointed out that for the convenience of bending and forming the wing edge, the indentation line provided with the indentation line in the middle of the rectangular cardboard is a wide indentation line, and the two sides of the indentation line correspond to the designed wing edge For cutting marks.

[0030] Preferably, the integrated cardboard has a convex structure, and the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com