Detachable seamless refrigerating cabinet door sealing tape and manufacture process thereof

A freezer door, seamless technology, applied in the field of door seals, can solve the problems of reduced sealing performance, low degree of automation, leakage of cold air in the freezer, etc., to achieve excellent sealing performance and thermal insulation performance, excellent anti-collision performance, and avoid cracking damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

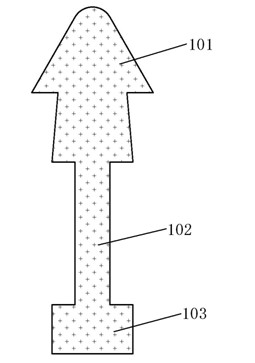

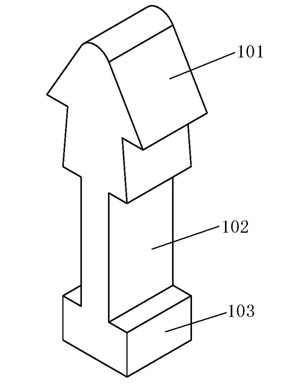

[0026] Such as figure 1 As shown, the door seal body 1 is a square frame structure composed of four frame sides that are compatible with the freezer door body, and the junction of the four corners is an R angle designed with a circular arc, which is used to disperse the collision stress and improve the door seal. anti-collision performance. The door seal body 1 is made of liquid polyurethane elastomer material through integral pouring and vulcanization without joints. It has excellent elasticity, high dimensional accuracy and is not easily deformed, and has excellent sealing and heat preservation properties. Such as figure 2 , 3 As shown, each frame side of the door seal body 1 includes a convex wedge 101 , a sealing heat preservation side 102 and a sealing pressing strip 103 . The convex wedge 101 is located at the upper part of the frame edge, and extends along its length to form a square frame, which is used to snap into the edge groove of the freezer door body to real...

Embodiment 2

[0030] Such as Figure 5 As shown, the bottom of the sealing and pressing strip 103 in this example has a circular arc-shaped structure, and the purpose is to increase the tightness between the door sealing strip and the cabinet body. A U-shaped groove can also be established in the middle part of the convex wedge 101 . Other structures and functions of this embodiment are the same as those of Embodiment 1.

[0031]

Embodiment 3

[0033] Such as Figure 6 As shown, in this example, the sealing and heat preservation edge 102 is designed to be bow-shaped, so as to increase the elastic tension of the seal and heat preservation edge 102, which is used to buffer the collision impact force when the freezer is closed. The bottom of the sealing pressing strip 103 is an arc-shaped structure. A U-shaped groove is arranged in the middle of the convex wedge 101 . Other structures and functions of this embodiment are the same as Embodiment 1 and Embodiment 2.

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com