Rotary sintering machine system

A sintering machine system and sintering machine technology are applied in the field of metallurgy, which can solve the problems of low power consumption, good product quality, and low air leakage rate in sinter production, and achieve the effects of improving sinter quality, reducing construction investment, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

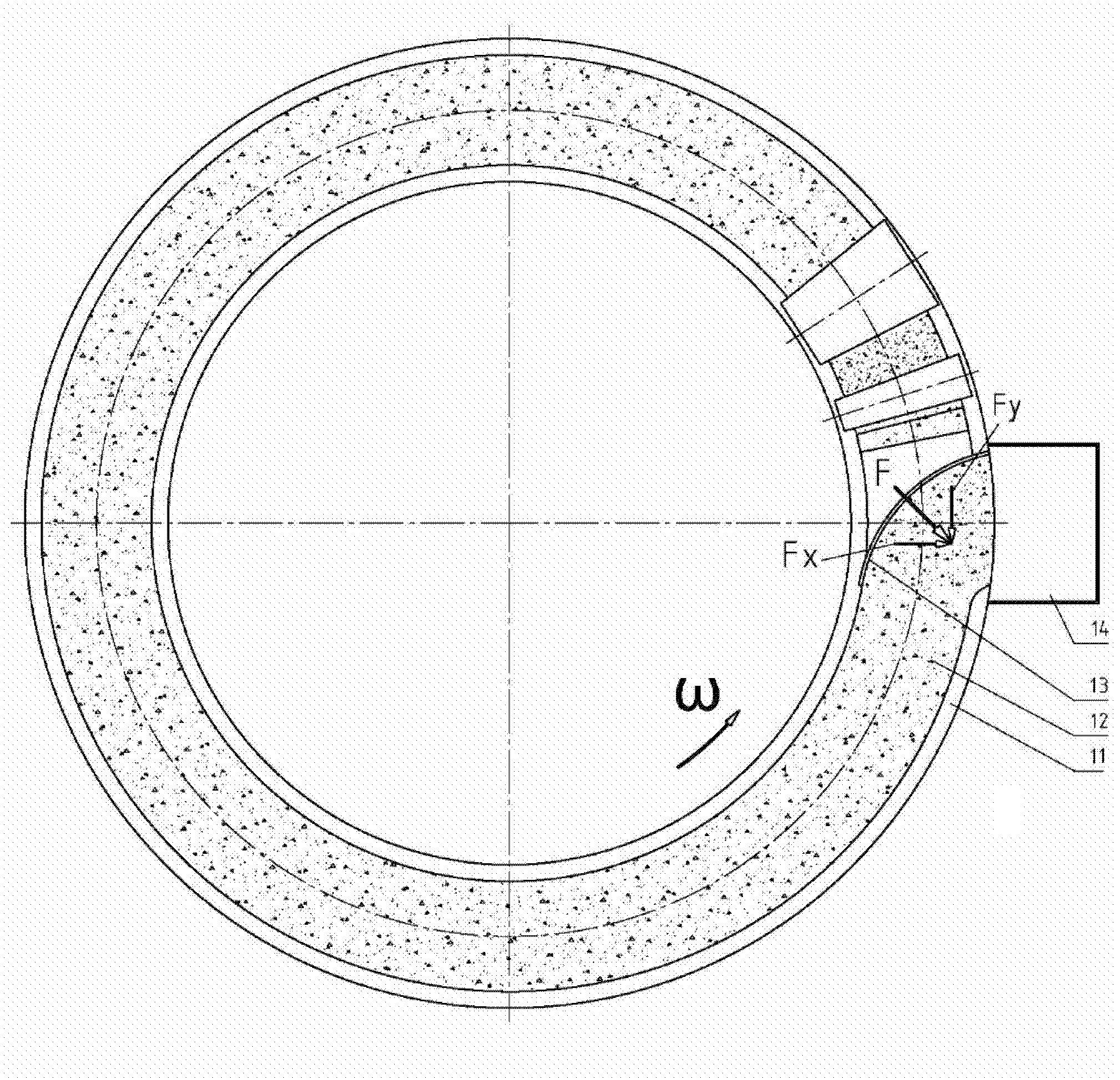

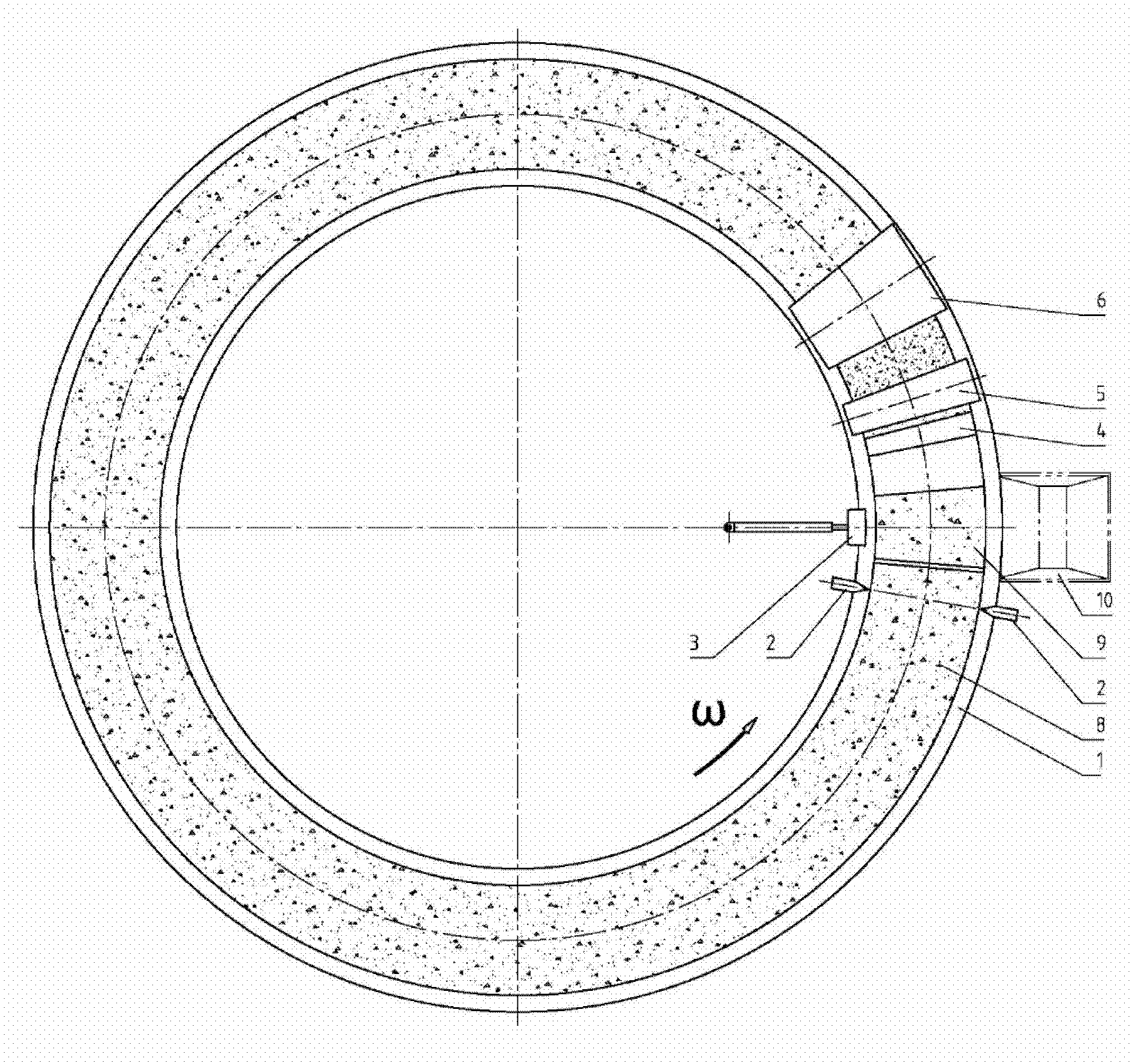

[0068] Embodiment 1 is to realize a kind of rotary sintering machine system of the present invention, in figure 2 Among them, 1 is the rotary sintering machine, 2 is the cutting device, 3 is the unloading device, 4 is the bed material device, 5 is the material distribution device, 6 is the igniter, 8 is the sinter cake, 9 is the short sinter cake, 10 is Crusher feed hopper.

[0069] The effective sintering area of the rotary sintering machine 1 is 300 square meters, the middle diameter is 28 meters, the effective width of the grate bed is 4 meters, the material layer height is 700 mm, the rotation direction is ω, the rotation speed is 1.3 revolutions per hour, and the middle diameter line The speed is 1.92 m / min. The bottom material device 4 is the same as the principle of the prior art, the distribution device 5 is the prior art that adopts the round roller feeder of the prior art to add the multi-roll distributor, and the igniter 6 is the prior art of using gas ignition....

Embodiment 2

[0074] Embodiment 2 is to realize a kind of rotary sintering machine system of the present invention, in figure 2 Among them, 1 is the rotary sintering machine, 2 is the cutting device, 3 is the unloading device, 4 is the bed material device, 5 is the material distribution device, 6 is the igniter, 8 is the sinter cake, 9 is the short sinter cake, 10 is Crusher feed hopper.

[0075] The effective sintering area of the rotary sintering machine 1 is 500 square meters, the middle diameter is 40 meters, the effective width of the grate bed is 5 meters, the material layer height is 800 mm, the rotation direction is ω, the rotation speed is 1.34 revolutions per hour, and the middle diameter line The speed is 2.78 m / min.

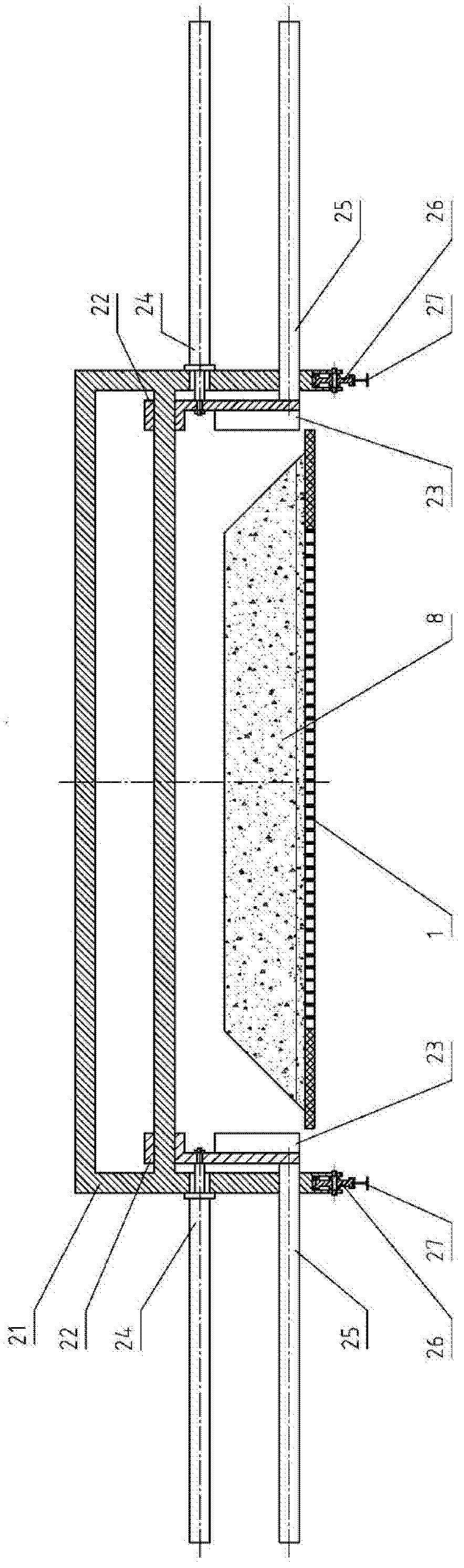

[0076] Figure 5 , Figure 6 It is a schematic diagram of the structure of the cutting device 2. The cutting device is a vertical cutting device. The cutting device keeps synchronous movement with the sinter cake during the pressing action, including a frame ...

Embodiment 3

[0080] Embodiment 3 is to realize a kind of rotary sintering machine system of the present invention, in figure 2 Among them, 1 is the rotary sintering machine, 2 is the cutting device, 3 is the unloading device, 4 is the bed material device, 5 is the material distribution device, 6 is the igniter, 8 is the sinter cake, 9 is the short sinter cake, 10 is Crusher feed hopper.

[0081] The total exhaust area of the rotary sintering machine 1 is 125 square meters, wherein the effective sintering area is 62.5 square meters, the cooling area is 62.5 square meters, the middle diameter is 16 meters, the effective width of the grate bed is 3 meters, and the height of the material layer is 800 mm. The direction of rotation is ω, the rotation speed is 1.24 revolutions per hour, and the pitch line speed is 1.01 m / min.

[0082] In this embodiment, 50% of the total ventilation area of the rotary sintering machine is used for cooling the sinter, that is, after the ventilation and sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com