Fiber bragg grating current transformer with automatic temperature tracking function and automatic temperature tracking method

A technology of current transformer and optical fiber grating, which is applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., to achieve the effect of real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

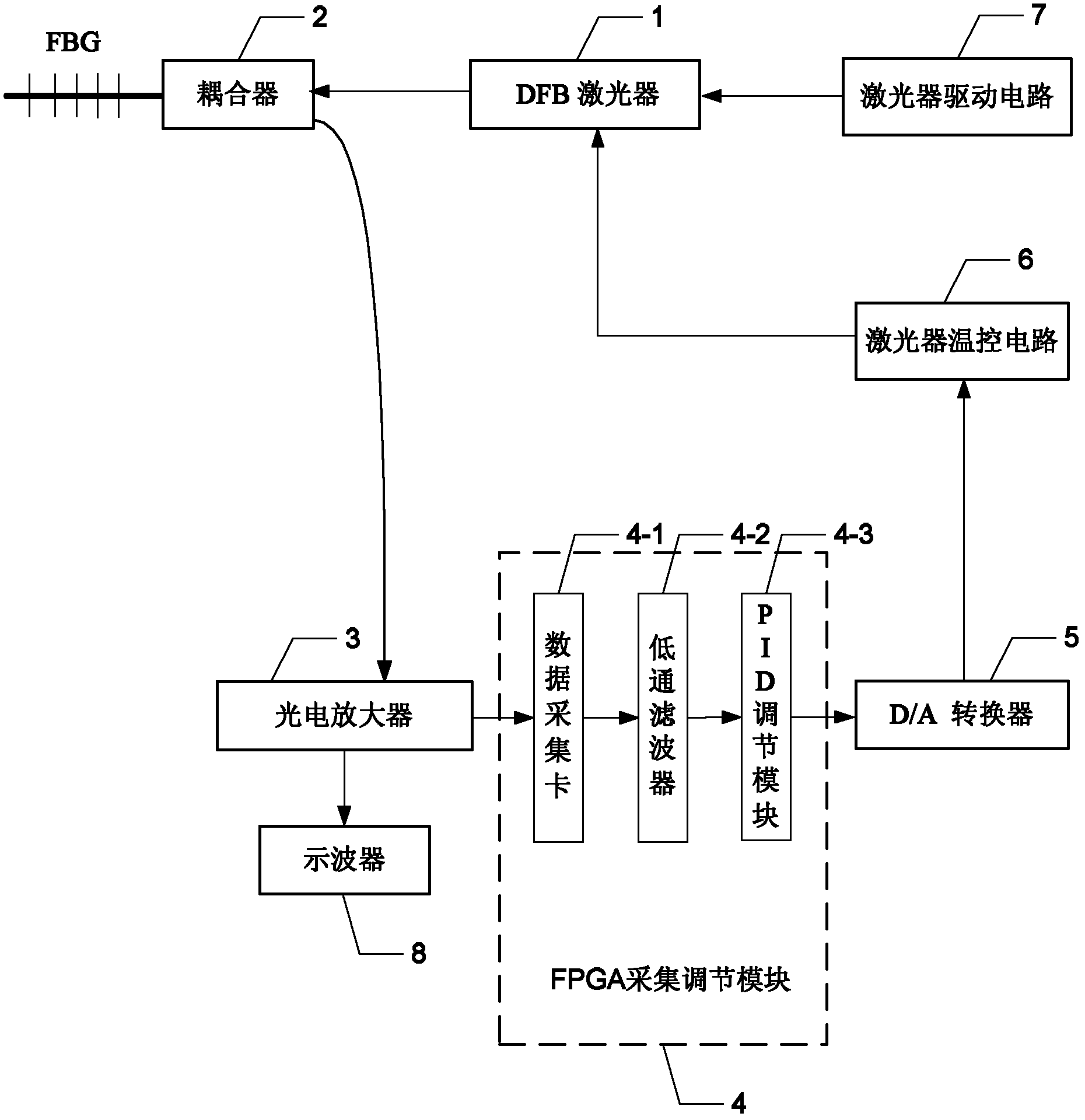

[0036] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment mode, a kind of fiber grating current transformer with automatic temperature tracking function described in this embodiment mode, it comprises DFB laser device 1, coupler 2, photoelectric amplifier 3, FPGA acquisition adjustment module 4, D / A converter 5 and laser temperature control circuit 6,

[0037] The laser light emitted by the DFB laser 1 enters the fiber grating through the coupler 2, and the light beam reflected by the fiber grating is output to the photoelectric amplifier 3 through the coupler 2, and the photoelectric amplifier 3 converts the input optical signal into an electrical signal and outputs it to the FPGA for acquisition and adjustment. Module 4, the feedback adjustment signal output end of the FPGA acquisition and adjustment module 4 is connected to the digital signal input end of the D / A converter 5, and the analog signal output end of the D / A...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment further describes Embodiment 1. It also includes a laser driving circuit 7 for driving the DFB laser 1 to work.

specific Embodiment approach 3

[0045] Embodiment 3: This embodiment further describes Embodiment 1. It also includes an oscilloscope 8 , and the display output end of the photoelectric amplifier 3 is connected to the display input end of the oscilloscope 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com