Packaging method for high-efficiency vertical coupling interconnection of optical fiber and optical waveguide chip

A technology of vertical coupling and packaging method, applied in the field of integrated optics, which can solve the problems of demanding fiber incident angle, inability to achieve repeatable operation, and high stability requirements of the coupling system, to achieve anti-interference array integration, overcome instability and The effect of repeatable alignment, easy array integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

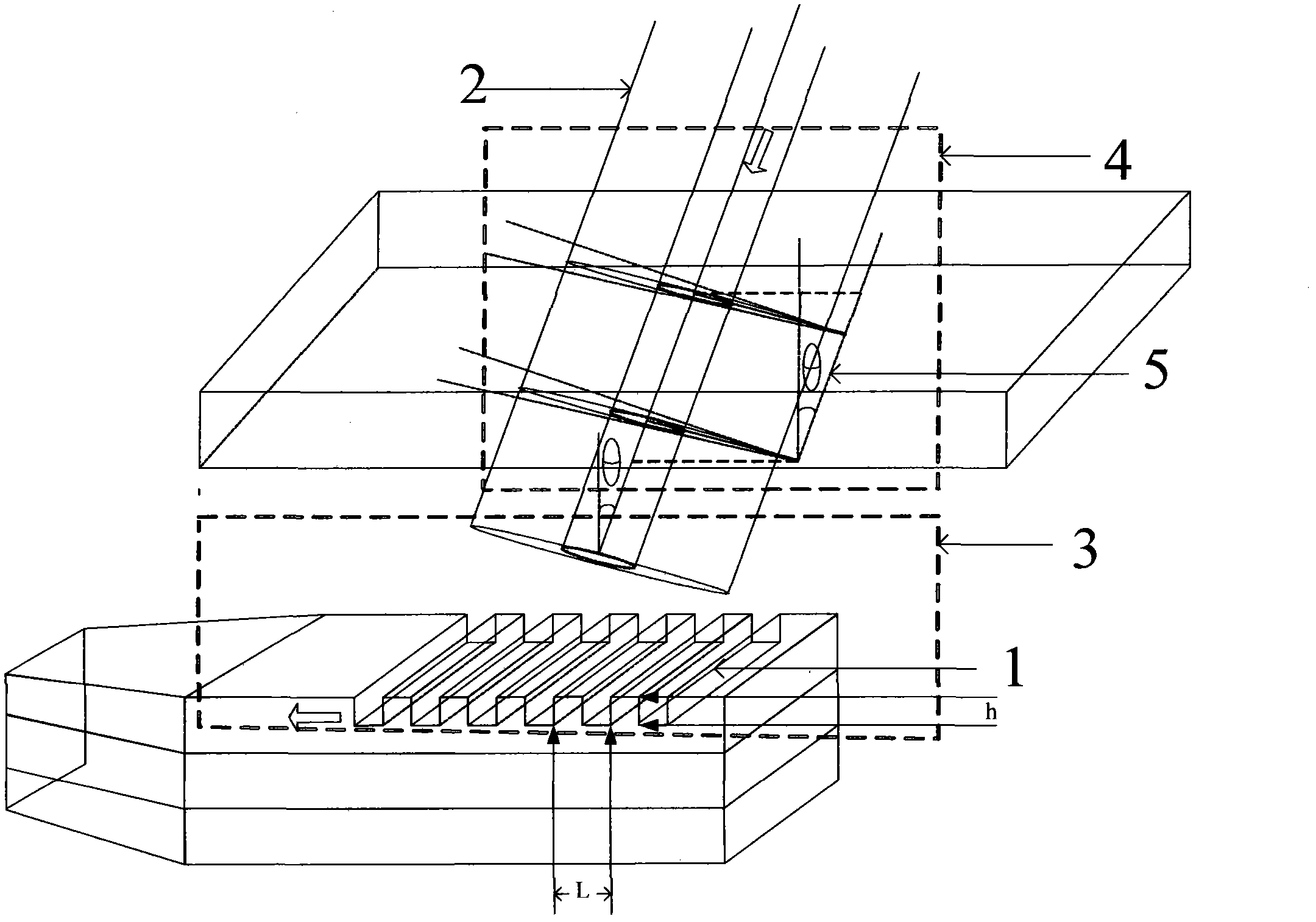

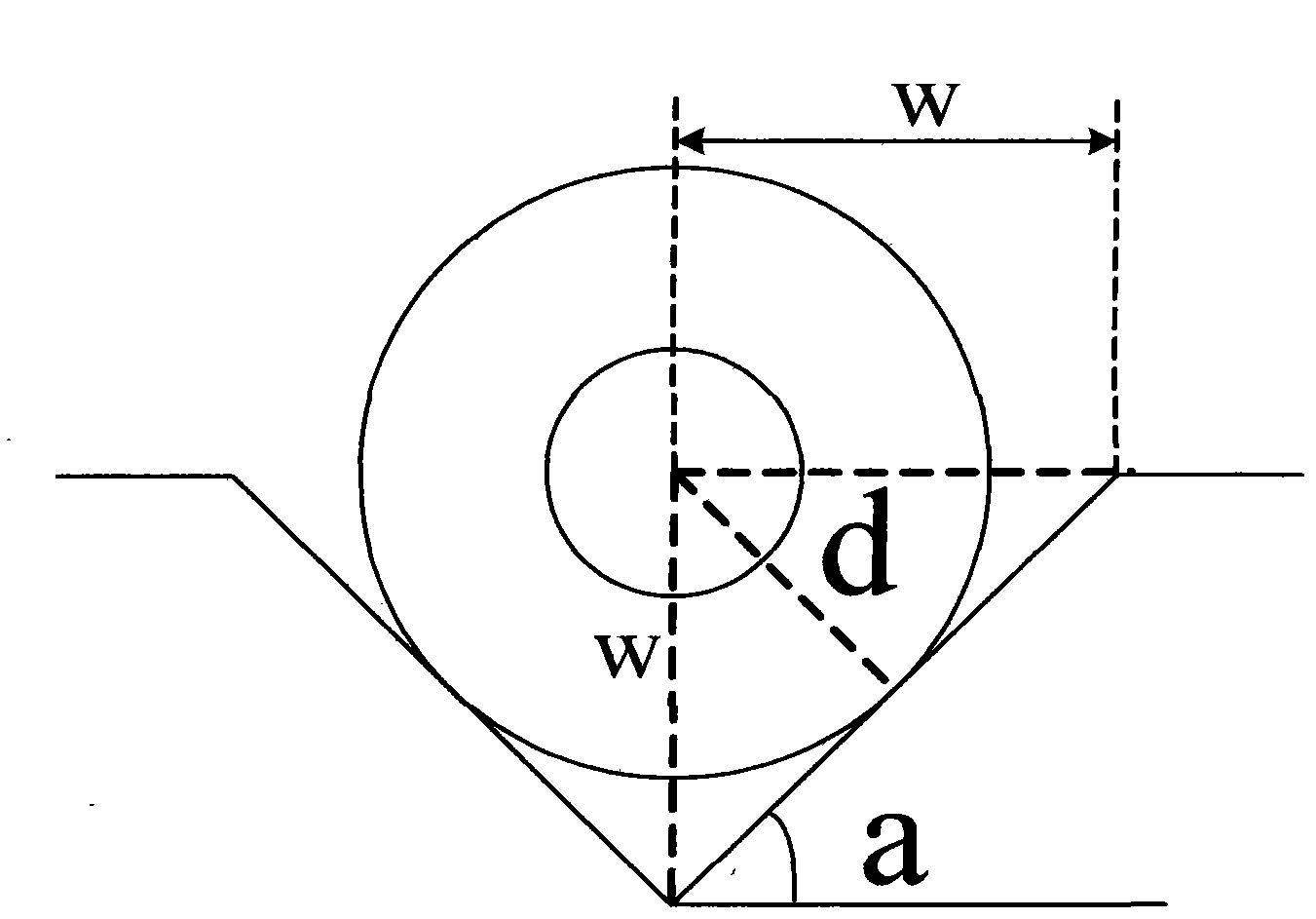

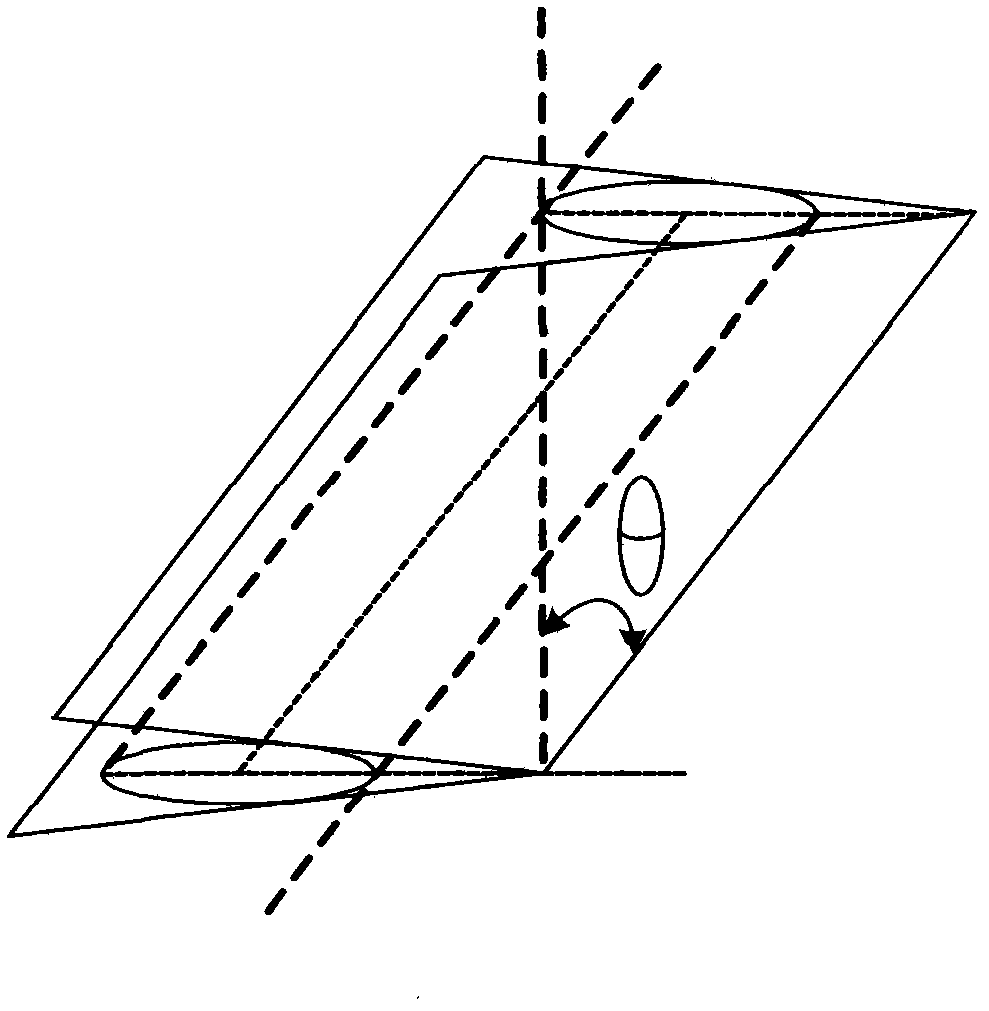

[0031] Such as figure 1 As shown, the coupling package structure includes a silicon-based nanowaveguide grating 1, a single-mode fiber 2, an inner package (coupling package end) 3, an outer package 4, and a V-shaped fiber positioning groove 5. The inclination angle of the V-shaped fiber positioning groove 5 is theta. The inner package is formed by dispensing and curing the refractive index matching paste coated on the surface of the grating and the planed vertical optical fiber by dispensing and curing the low refractive index ultraviolet curing adhesive material. The external packaging body is mainly composed of an external packaging box containing the entire grating and an internal packaging body, and its top has a through V-shaped optical fiber positioning groove. The duty ratio of the silicon-based nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mode field diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com