Plane parallel three-degree-of-freedom precise operating platform

A technology of operating platform and degrees of freedom, applied in microscopes, optics, instruments, etc., can solve the problem that the displacement resolution of piezoelectric actuators and flexible hinge structures cannot be effectively used, and the high-precision motion accuracy, end motion accuracy and positioning of the operating platform cannot be achieved. Accuracy reduction and other problems, to achieve the effect of wide practicability, increase the range of motion, and reduce the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

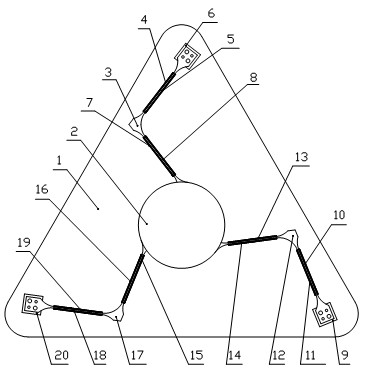

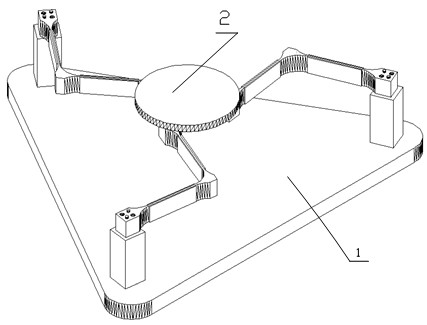

[0019] Such as figure 1 and figure 2 As shown, the brackets 6, 9, 20 are fixedly connected on the base 1, and the stage 2 is connected to the brackets 6, 9, 20 through three flexible transmission links 3, 12, 17. The three flexible transmission links 3 , 12 , 17 are distributed around the stage 2 in sequence.

[0020] One end of the flexible transmission link 3 is fixedly connected to the support 6, and the other end is fixedly connected to the stage 2; one end of the flexible transmission link 12 is fixedly connected to the support 9, and the other end is fixed to the stage 2 Connection; one end of the flexible transmission link 17 is fixedly connected to the bracket 20 , and the other end is fixedly connected to the stage 2 .

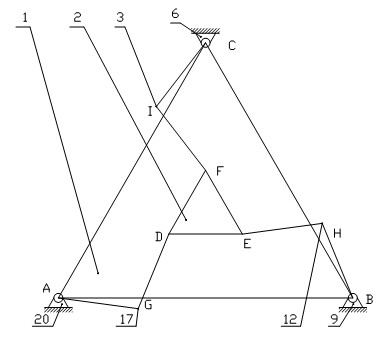

[0021] Such as image 3 As shown, the geometric centers C, B, A of the connecting parts of the brackets 6, 9, 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com